This is a shameless plug but I can certainly help...I offer front horns plans on my website. I include the AutoCAD files as well.

I have a growing number of different designs, and I can customize to your needs since I’m an avid Solidworks user able to do flat shapes from bent wood designs.

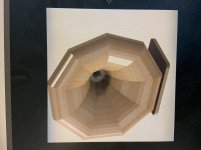

Summer Rain Front Horn for BG Neo8, flat response from 180Hz -20kHz

Mini Version (25% smaller) 280Hz -20kHz

Or

Summer Rain Front Horn using 8” diameter driver...180Hz - 3kHz (driver dependant).

Summer Rain Front Horn Drawing Package – Joseph Crowe

What bandwidth of horn are you looking for? I recently built a small Yuichi biradial that uses the Beyma TPL-150.

I have a growing number of different designs, and I can customize to your needs since I’m an avid Solidworks user able to do flat shapes from bent wood designs.

Summer Rain Front Horn for BG Neo8, flat response from 180Hz -20kHz

Mini Version (25% smaller) 280Hz -20kHz

Or

Summer Rain Front Horn using 8” diameter driver...180Hz - 3kHz (driver dependant).

Summer Rain Front Horn Drawing Package – Joseph Crowe

What bandwidth of horn are you looking for? I recently built a small Yuichi biradial that uses the Beyma TPL-150.

Yuichi's site is hanging on only in the internet archive.

Very important resource -

?z?[???X?s?[?J?[

Speaker Drawings

I made a version of the A290S , scaled by 0.707 for 1.4" drivers, so that's a 415Hz horn. Very good indeed.

Very important resource -

?z?[???X?s?[?J?[

Speaker Drawings

I made a version of the A290S , scaled by 0.707 for 1.4" drivers, so that's a 415Hz horn. Very good indeed.

Very nice, I have been hoping for an FLH, FLH/BLH from Dr @Scottmoose...This is a shameless plug but I can certainly help...I offer front horns plans on my website. I include the AutoCAD files as well.

I have a growing number of different designs, and I can customize to your needs since I’m an avid Solidworks user able to do flat shapes from bent wood designs.

-

Summer Rain Front Horn using 8” diameter driver...180Hz - 3kHz (driver dependant).

Summer Rain Front Horn Drawing Package – Joseph Crowe

What bandwidth of horn are you looking for? I recently built a small Yuichi biradial that uses the Beyma TPL-150.

Do you have a Summer Rain FH/8"ø driver design variant for use with a 6.5"ø Fostex and or MarkAudio driver?

I offer CAD CNC files for Yuichi 290S.

I’ll take you up on that Andrew… or the precursor CAD plans

dave

Very nice, I have been hoping for an FLH, FLH/BLH from Dr @Scottmoose...

Do you have a Summer Rain FH/8"ø driver design variant for use with a 6.5"ø Fostex and or MarkAudio driver?

I have plans for a 300Hz JMLC x9 pedal wood horn that can use 4”-5” fullrange drivers. I’m currently waiting for the FE126EN on back order from Solen.

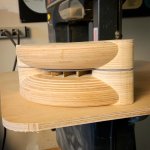

The outside diameter is 24”. It uses bent plywood by soaking in hot water for five minutes. Two layers of 3mm thick Baltic Birch Plywood for the Horn walls.

Flat packs will be available July timeframe. The plans are complete but I’m validating the design once the drivers arrive. It would ideally be suited to use a wood phase plug (see photo).

I purchased a RouterParts Pro Benchtop CNC router which arrives mid May. I’m very excited to start using this machine! 🙂

Attachments

Happy to help, Dave.I’ll take you up on that Andrew… or the precursor CAD plans

dave

Joseph, from one (CNC/CAD) horn builder to another, very well done. How do you fix the individual petals together once bent/dried? Also, can you accommodate a 2-inch throat? Regards.

Joseph, from one (CNC/CAD) horn builder to another, very well done. How do you fix the individual petals together once bent/dried? Also, can you accommodate a 2-inch throat? Regards.

Hi Mr.Trucco, the rear support ribs provide all the strength and rigidity. The pedals are left with a 90 degree cut edge, this forms a vee-groove at the seam on the back side that acts as a glue prep. Run a bead of glue down down this seam to provide the necessary air seal, and further strengthen/stiffen the structure, but it’s not the primary support. The bending of the pedals relies on a holding fixture that requires construction and is detailed out in the plans. This fixture holds one pedal and support rib and allows bending the pedal and holds everything in place while the glue dries between the pedal and support rib.

I’ve tested it and the glue still cures fine even when the wood pedal is soaking wet. It’s kinda fun too.

Great, thanks for reply, Joseph.Hi Mr.Trucco, the rear support ribs provide all the strength and rigidity. The pedals are left with a 90 degree cut edge, this forms a vee-groove at the seam on the back side that acts as a glue prep. Run a bead of glue down down this seam to provide the necessary air seal, and further strengthen/stiffen the structure, but it’s not the primary support. The bending of the pedals relies on a holding fixture that requires construction and is detailed out in the plans. This fixture holds one pedal and support rib and allows bending the pedal and holds everything in place while the glue dries between the pedal and support rib.

I’ve tested it and the glue still cures fine even when the wood pedal is soaking wet. It’s kinda fun too.

And can you kindly confirm if this type of horn can be made with a two inch throat, suitable for compression drivers? Regards. Andrew.

Yes everything about the design is customizable since it’s just me doing all the CAD,CAM, and cutting. There’s no tooling involved so it’s a flexible process.

Actually all the horns I build are one-off projects. The flat packs will be built-to-order as well for this purpose.

Actually all the horns I build are one-off projects. The flat packs will be built-to-order as well for this purpose.

Good one...I enjoyed going through a few of your Youtube clips...well done for posting them in such a helpful and clear way.Yes everything about the design is customizable since it’s just me doing all the CAD,CAM, and cutting. There’s no tooling involved so it’s a flexible process.

Actually all the horns I build are one-off projects. The flat packs will be built-to-order as well for this purpose.

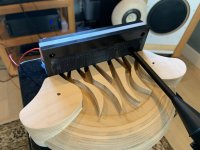

I'm currently building a large 3 way horn system, dual AE TDM10's, Jabo 350Hz horn with Radian beryllium drivers, and Beyma TPL150 tweeter...all CNC'd in euro birch ply.

Attachments

Wow amazing stuff. I’m using the TPL-150H with the B&C 12PE32 as a 2-way in my smaller listening room. I’ve done a couple of different custom horns for this driver. One was a little bi-radial using the JMLC flare in both axis. The vanes kept the wavefront time aligned to reduce cancelation effects.

Attachments

- Home

- Loudspeakers

- Full Range

- Front loaded wood horn Plans