I really like the all-white look of the Fostex FE83-sol and FE103En drivers, but am concerned about the extremely low xmax numbers (less than 1mm).

So I'm looking at some black or black/white drivers and the possibility of applying a thin coat of white paint which hopefully would not impact cone breakup. I will measure the on-axis and off-axis frequency response before and after to confirm. It looks difficult to spray cleanly without getting paint on the rubber surround, so I'm thinking brush-on would be better...

Does anyone have experience/recommendations on paint for paper, plastic, and/or aluminum cones? Any concerns about causing glues to deteriorate?

So I'm looking at some black or black/white drivers and the possibility of applying a thin coat of white paint which hopefully would not impact cone breakup. I will measure the on-axis and off-axis frequency response before and after to confirm. It looks difficult to spray cleanly without getting paint on the rubber surround, so I'm thinking brush-on would be better...

Does anyone have experience/recommendations on paint for paper, plastic, and/or aluminum cones? Any concerns about causing glues to deteriorate?

Your music will sound white. … I'm kidding, but I have painted several speakers with a thin coat of spray paint and never had issues (50cm away). Well they were meant for staying behind grilles, so aesthetic was not an issue. You can always carefully tape the rubber surround before painting.

Painting white onto a black surface is problematical. Best to apply a grey primer first. Brush painting is likely to give a streaky appearance, so spray application is recommended. Apply several light coats until the required coverage is obtained. Ensure each coat is completely dry before applying the next. Careful masking of the rubber surround will be required.

P.S. Acrylic spray paint, as used for plastic model kits, should not affect adhesives.

P.S. Acrylic spray paint, as used for plastic model kits, should not affect adhesives.

Last edited:

It may not affect adhesives, but it will change the response behaviour. Wideband cone drivers generate much of their response through [more or less depending] resonant action of the cone substrate. Painting it will in essence add a damping layer; how much depending on the elasticity of the paint and the mass applied. Only very small masses are needed to create an overall (or localised) effect, so coating the entire cone in primer & an upper layer is likely to reduce HF at the very least, and probably some midband also.

Depending on what you are doing, a point to keep in mind is that

a/ There is no industry standard definition for Xmax, and

b/ Xmax is not a line in the sand; it is not unless otherwise specified the mechanical limit of travel (Xmech), and does not tell you much about driver behaviour. Some drivers overload more gracefully than others; it depends on the suspension and particularly the motor design, neither of which Xmax tell you. To get a better idea of that, you need to measure the individual harmonic distortion levels; 2nd through 5th is usually sufficient. Forget THD, it's almost useless since different types of distortion affect the sound in different ways, and lumping them into a summed value prevents you from assessing these.

FWIW, Fostex drivers typically overload with a reasonable amount of grace & have plenty of mechanical travel beyond Xmax; the drivers are usually suspension limited before you belt the VC off the back-plate too, although anyone with more mechanical sympathy than Captain Caveman (aka a modicum of common sense) is unlikely to get to this point anyway as they'd turn the wick down.

Depending on what you are doing, a point to keep in mind is that

a/ There is no industry standard definition for Xmax, and

b/ Xmax is not a line in the sand; it is not unless otherwise specified the mechanical limit of travel (Xmech), and does not tell you much about driver behaviour. Some drivers overload more gracefully than others; it depends on the suspension and particularly the motor design, neither of which Xmax tell you. To get a better idea of that, you need to measure the individual harmonic distortion levels; 2nd through 5th is usually sufficient. Forget THD, it's almost useless since different types of distortion affect the sound in different ways, and lumping them into a summed value prevents you from assessing these.

FWIW, Fostex drivers typically overload with a reasonable amount of grace & have plenty of mechanical travel beyond Xmax; the drivers are usually suspension limited before you belt the VC off the back-plate too, although anyone with more mechanical sympathy than Captain Caveman (aka a modicum of common sense) is unlikely to get to this point anyway as they'd turn the wick down.

I agree that painting a speaker cone is not a good idea, but at least the OP now knows how to do it - at his own risk of course!It may not affect adhesives, but it will change the response behaviour.

Yep, since they have no low rangeEnough paint to make your cones white will make your driver a midrange.

Xmax is for chumps. Don't be a chump. ;-)

Xmax can be a marginally useful parameter, with the T/S numbers, but by itself it's just for marketing.

With a FR driver you'll really want the driver to move as little distance as possible.

That can either be done by a large diaphragm or by loading a smaller driver, and you'll still get acceptable bass.

Xmax can be a marginally useful parameter, with the T/S numbers, but by itself it's just for marketing.

With a FR driver you'll really want the driver to move as little distance as possible.

That can either be done by a large diaphragm or by loading a smaller driver, and you'll still get acceptable bass.

Enough paint to make your cones white will make your driver a midrange.

+1, but more of a midbass if it has any natural bass performance.

I have lots of experience with coating cones. Adding too much tends to kill the top end. Trying to make a dark cone white is problematic. My experience says to use as little coating as possible, which means cones can only get “darker” in colour.

Another point… there is no real standard for specifiying xMax so it is hard to directly compare.

The Fostex FE series may have a small xMax but the xDesruct (xMech) is way higher. If you need to play louder than they can do, add helper woofers and make a WAW.

dave

Yeah, to get a solid white over black without a primer requires either a thick paint job or using sign painter's white, which is loaded with alum. dust and no, it doesn't add a metallic/'bright' sound to it, but sure looks good. Not as thick a job as the others, but still too thick for a 'FR' driver.

GM

GM

have a look at the SB Acoustics Satori Midrange, the 5" is available in white that may do the job -

SB Acoustics :: 5” SATORI MR13PNW-8

SB Acoustics :: 5” SATORI MR13PNW-8

Sticking to the topic, how about making paper cones darker?

Since many are saying that paint layers will probably change the resonance/top-end/characteristics of a speaker, how about dying (dye) them instead (paper cones only)?

Assuming that it will not warp the paper cones (oil based stain perhaps? Or just a very thin layer of water dye?), will it still possibly have any effect on the sonic signature of the speaker?

Since many are saying that paint layers will probably change the resonance/top-end/characteristics of a speaker, how about dying (dye) them instead (paper cones only)?

Assuming that it will not warp the paper cones (oil based stain perhaps? Or just a very thin layer of water dye?), will it still possibly have any effect on the sonic signature of the speaker?

Assuming that it will not warp the paper cones (oil based stain perhaps? Or just a very thin layer of water dye?), will it still possibly have any effect on the sonic signature of the speaker?

Alcohol based, none according to my daughter's then youthful hearing nor much later with a woman that could perceive a dog whistle. Small drivers were airbrushed, large with a touch-up gun though, so no experience with any brush/wipe on applications.

Great for sun bleached drivers, my only reason for taking the time except for one set of woofers that got a Krylon metallic blue lacquer spray bomb paint job, not caring if its HF response was modified.

GM

If driver have whitish color of membrane it usually implicates that it is natural color of paper. That kind of paper coming from tradition of hand made papers for different purposes but mainly for hand print and fine art. Some brands are using hand made paper for cones even today...

.

Fostex have good cones from very good paper quality. All of the paper sheets have some "glue", something to keep the structure rigid and firm.

.

With applying as-is paint, usually synthetic, with hard solvents, can weak od damage natural structure. Applying water-based acrylic paint could be fatal...

.

DO NOT Paint natural paper cones, just because You do not like the way they look PLEASE.

.

The more convenient way will be to make solution based on Damar lacquer (hard pieces) in pure Turpentine (dont use ready made solutions...). Damar is product of tree and it is hard resin. Dont mind about some wood pieces they will come down to bottom. Turpentine is soft natural resin and will not damage the material. Also it vaporize quick. You can use Medical Benzine too. Every other solvent is too hard, and in some cases can penetrate and damage glue with coil former and cone...

.

2 very thin layers are enough. Some practice on other paper is welcome. Also the brush is from importance. Brush have to be soft, with moderate length. Tip is to have not much lack in the brush. Before applying every time move out some amount of liquid from the brush.

Additionally You can add some little amount of natural Lanolin into the solution. The finest one is in the Breast-recovery tubes and it is easily finds in drug and medical stores.

.

Solution have to be in density like yogurt for example. Do not put too many pieces of Damar in the turpentine. You can use spoon or something else to made powder from pieces of damar on sheet of paper, that will speed up the process of dissolution.

.

It cant add significant additional mass to the cone, like spray or other paint. And it is also good for double cone drivers where little center cone could be treated with 3-4 layers of this solution.

.

Fostex have good cones from very good paper quality. All of the paper sheets have some "glue", something to keep the structure rigid and firm.

.

With applying as-is paint, usually synthetic, with hard solvents, can weak od damage natural structure. Applying water-based acrylic paint could be fatal...

.

DO NOT Paint natural paper cones, just because You do not like the way they look PLEASE.

.

The more convenient way will be to make solution based on Damar lacquer (hard pieces) in pure Turpentine (dont use ready made solutions...). Damar is product of tree and it is hard resin. Dont mind about some wood pieces they will come down to bottom. Turpentine is soft natural resin and will not damage the material. Also it vaporize quick. You can use Medical Benzine too. Every other solvent is too hard, and in some cases can penetrate and damage glue with coil former and cone...

.

2 very thin layers are enough. Some practice on other paper is welcome. Also the brush is from importance. Brush have to be soft, with moderate length. Tip is to have not much lack in the brush. Before applying every time move out some amount of liquid from the brush.

Additionally You can add some little amount of natural Lanolin into the solution. The finest one is in the Breast-recovery tubes and it is easily finds in drug and medical stores.

.

Solution have to be in density like yogurt for example. Do not put too many pieces of Damar in the turpentine. You can use spoon or something else to made powder from pieces of damar on sheet of paper, that will speed up the process of dissolution.

.

It cant add significant additional mass to the cone, like spray or other paint. And it is also good for double cone drivers where little center cone could be treated with 3-4 layers of this solution.

DO NOT Paint natural paper cones

I literally have 100s of drivers out there with cones painted with ModPodge/Puzzlekoat (PVA). A coat (actually 2) of thinned acrylic goes on top after the spots.

I do not advise added too much damar. It stiffens the cone and can cause ringing.

dave

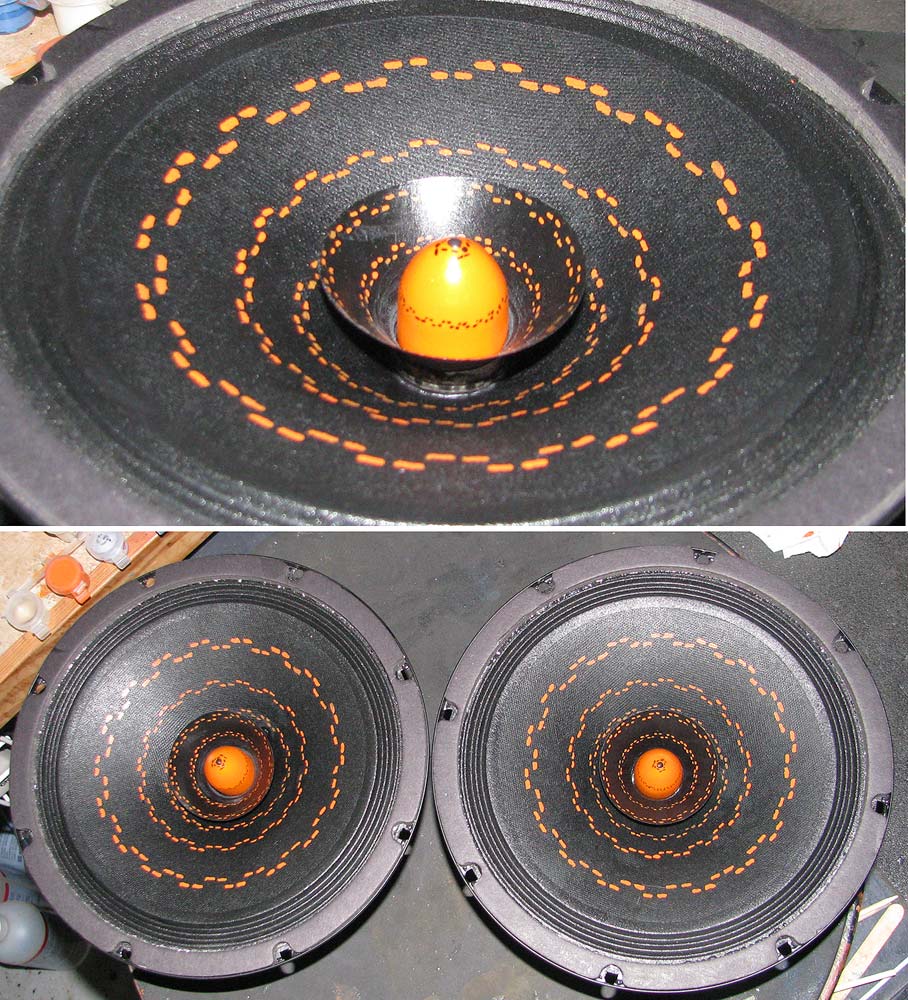

I used thinned modpodge (but not as thin as to warp the cone) with black colourin gin it to move “black” coned paper drivers closer to black.

Alpair blue:

Thanks for the pictures Planet10. May I know what type of black coloring did you use to mix with the ModgePodge? I'm interested in "painting black" the Alpair 10P likes yours. Other than aestheics, what improvements did it make to the sound of the Alpair 10P?

The black food colouring i have is actually an ugly green in the quantities i use. So for black a combination of black ink (actually a dark, dark blue) + a bit of acriylic train paint.

Puzzlekoat/ModPodge is something i have used sinece the late ‘70s. Speaker Tweeks -- Puzzlecoat & Ductseal

dave

Puzzlekoat/ModPodge is something i have used sinece the late ‘70s. Speaker Tweeks -- Puzzlecoat & Ductseal

dave

What about using black India ink? It’s just lampblack (soot) and water and it doesn’t require a binder. I’ve used it on the interiors of wood turned vases to get a “bottomless black” look. I don’t imagine it would add much mass and it doesn’t take much to turn lighter colored wood black. I imagine paper cones would take it quite well.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Painting fullrange driver cone