Hi can someone (because I am not familiar with speaker design software) simulate an appropriate MLTL for my old fostex fe168sigma (whizzer) because BIB cabinet probably wont pass the WAF test . I found something that looks interesting on youtube but there is no data on the construction.

https://www.youtube.com/watch?v=7fxtMqj3UWA .

My room is about 25 square meters and I plan to stick them to back walls as close as I can .

https://www.youtube.com/watch?v=7fxtMqj3UWA .

My room is about 25 square meters and I plan to stick them to back walls as close as I can .

Last edited:

Does the FH-XL pass WAF in your case?

The Frugel-Horn

However, not sure if the FE-168 Sigma will work in that cab - there is a possibility that it will. If the design meets your criterion of acceptability, then maybe the FH-XL design team can comment on driver suitability.

The Frugel-Horn

However, not sure if the FE-168 Sigma will work in that cab - there is a possibility that it will. If the design meets your criterion of acceptability, then maybe the FH-XL design team can comment on driver suitability.

Well maybe but now the problem is that the cabinet is quite deep and will reduce living space .I prefer something with the BIB footprint (20+- cm x 30+- cm)but usual speaker height. .There was a proposal from Bob Brines years ago here Proposals but the images aren't displayed but I would like a 2017 view on construction stuffing etc etc .Here are some photos of my living room as you can see I have limited space for big constructions...

.There was a proposal from Bob Brines years ago here Proposals but the images aren't displayed but I would like a 2017 view on construction stuffing etc etc .Here are some photos of my living room as you can see I have limited space for big constructions...

Last edited:

Greets!

Amp? If a high output impedance, then ideally need to know its value in ohms or at least its DF [damping factor, not terminal connection value], otherwise cab may be too small, hence too 'boomy', requiring ideally too much stuffing.

Also, do you want the driver at your average seated ear height or......to listen vertically off axis?

GM

Amp? If a high output impedance, then ideally need to know its value in ohms or at least its DF [damping factor, not terminal connection value], otherwise cab may be too small, hence too 'boomy', requiring ideally too much stuffing.

Also, do you want the driver at your average seated ear height or......to listen vertically off axis?

GM

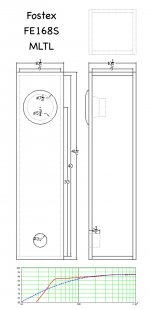

Quick draft using published specs with average seated ear height yields a minimum ~60"/152.4 cm H x 8.45"/21.45 cm W x 4.14"/10.5 cm D [inside dims] tuned to ~42 Hz with a baffle thickness [0.75"/1.9 cm] cutout the way I like to design MLTLs, so not 'cast in stone'. Add a double thickness [1.5"/3.8 cm] base plate and minimal damping on the top, back and one side with 1" acoustic fiberglass insulation or similar.

GM

GM

The amp is a tube el34 single ended (probably with some feedback) 8 ohm taps only and about 10 watt .Greets!

Amp? If a high output impedance, then ideally need to know its value in ohms or at least its DF [damping factor, not terminal connection value], otherwise cab may be too small, hence too 'boomy', requiring ideally too much stuffing.

Also, do you want the driver at your average seated ear height or......to listen vertically off axis?

GM

My listening height is about 90 cms.

OK, then will increase net volume [Vb] a bit:

H = 60"/152.4 cm

W = 11.25"/28.57 cm

D = 4.14"/10.5 cm

Driver down 25.2"/64 cm

Vent down 50.4"/128 cm

Vent dia. = 2"/5.08 cm

Vent length = 0.75"/1.9 cm

All dims are inside [i.d.] and approximate, so can round up to nearest whole number as required/desired.

Add a double thickness [1.5"/3.8 cm] base plate and minimal damping on the top, back and one side with 1" acoustic fiberglass insulation or similar is normally sufficient, though a good plan to be able to add extra damping in the area above, around, the driver with a removable top plate.

Mass loading helps performance too, so adding a block to the rear wall behind the driver to provide a slight pressure when mounting the driver and adding a massive [Marble, slate or similar] top plate to cover the removable one really helps such a tall, thin, light tower.

FWIW I mount these with industrial grade Velcro. That, or just a wood top and Velcro a heavy plant, which of course has great WAF. Depending on how large, massive you make the bases, these might need to be Velcroed to the wall near their tops too.

GM

PS: Please disable the Tapatalk ad, TIA.

H = 60"/152.4 cm

W = 11.25"/28.57 cm

D = 4.14"/10.5 cm

Driver down 25.2"/64 cm

Vent down 50.4"/128 cm

Vent dia. = 2"/5.08 cm

Vent length = 0.75"/1.9 cm

All dims are inside [i.d.] and approximate, so can round up to nearest whole number as required/desired.

Add a double thickness [1.5"/3.8 cm] base plate and minimal damping on the top, back and one side with 1" acoustic fiberglass insulation or similar is normally sufficient, though a good plan to be able to add extra damping in the area above, around, the driver with a removable top plate.

Mass loading helps performance too, so adding a block to the rear wall behind the driver to provide a slight pressure when mounting the driver and adding a massive [Marble, slate or similar] top plate to cover the removable one really helps such a tall, thin, light tower.

FWIW I mount these with industrial grade Velcro. That, or just a wood top and Velcro a heavy plant, which of course has great WAF. Depending on how large, massive you make the bases, these might need to be Velcroed to the wall near their tops too.

GM

PS: Please disable the Tapatalk ad, TIA.

I have found also some ideas about the finishing ,at this company's model (Magno) ,a little taller than theirs but I believe the WAF is ok . ( Geometric Harmony Speakers - Basic )

I plan to have them very close to back wall It will be ok?

I plan to have them very close to back wall It will be ok?

Sorry for my ignorance but I have some questions in order to learn something from the built...

Why do we need to double the top and the bottom ? Logically the smallest surfaces are more rigid than the baffle and the back of the cabinet why we aim these parts?

Do we have to enforce with internal braces the back and the baffle as well the sides or bouble them as well?

Do we need as less resonant cabinet as can be or the cabinet is somehow tuned to resonate in some areas on purpose.

Why do we need to double the top and the bottom ? Logically the smallest surfaces are more rigid than the baffle and the back of the cabinet why we aim these parts?

Do we have to enforce with internal braces the back and the baffle as well the sides or bouble them as well?

Do we need as less resonant cabinet as can be or the cabinet is somehow tuned to resonate in some areas on purpose.

I'm not GM, but FWIW, the top is the high pressure area, so ideally you want to make it as rigid as possible. And if you can put something suitably heavy on it, so much better as you'll mass load all the panels into the floor.

I'd double the front baffle as a minimum since you can't really have too rigid an enclosure, and it's the weakest part of the structure with the large hole cut in it. Bracing is good; ideally the cross-brace type that Dave (planet10) favours to couple all panels together. Just make sure it doesn't disrupt the longitudinal standing wave since GM has designed you a 'real' MLTL. I very much doubt the panels are intended to audibly resonanate, as that would be colouration, and he's not big on that.

I'd double the front baffle as a minimum since you can't really have too rigid an enclosure, and it's the weakest part of the structure with the large hole cut in it. Bracing is good; ideally the cross-brace type that Dave (planet10) favours to couple all panels together. Just make sure it doesn't disrupt the longitudinal standing wave since GM has designed you a 'real' MLTL. I very much doubt the panels are intended to audibly resonanate, as that would be colouration, and he's not big on that.

A bracing like this should work ?

http://www.frugal-phile.com/boxlib/GM-A10-MLTL.pdf

http://www.frugal-phile.com/boxlib/GM-A10-MLTL.pdf

Interestingly, the large ported box designed by Nagoaka has the same internal volume as GMs design, approx 1.6cf. Great minds think alike.

Attached is an older Brines design for the 168S that's about 1.8cf.

In my experiments, reducing the box volume for this driver to below 1cf really reduces the bass output and thins out the sound. The balancing act is critical with the Fostex 168s.

Attached is an older Brines design for the 168S that's about 1.8cf.

In my experiments, reducing the box volume for this driver to below 1cf really reduces the bass output and thins out the sound. The balancing act is critical with the Fostex 168s.

Attachments

I draw a quick plan on mspaint I hope is gonna do the job ...

I plan to have them very close to back wall It will be ok?

Thanks GM

You're welcome!

Looks good to me, though again these are inside dims [i.d.].

Yes, tuned this far below Fs they need to be and one reason why I suggested maybe Velcroing them to the wall.

GM

Sorry for my ignorance but I have some questions in order to learn something from the built...

Why do we need to double the top and the bottom ? Logically the smallest surfaces are more rigid than the baffle and the back of the cabinet why we aim these parts?

Do we have to enforce with internal braces the back and the baffle as well the sides or bouble them as well?

Do we need as less resonant cabinet as can be or the cabinet is somehow tuned to resonate in some areas on purpose.

What all Scott said plus if made using ~3/4"[1.9 cm] thick no void plywood [BB, apple, marine grade], then with such a high aspect ratio it won't need much bracing except around the driver. A single vertical riser board along ~70% of the baffle's, rear panel's height is sufficient. The sides are too narrow to worry about since most of the acoustic pressure is vertical.

If you build it out of thinner material or MDF, then the goal is to tie all six sides together to keep it from 'breathing', tying these to the driver motor brace like shown in Dave P10's drawings. No need to make time consuming holey braces, just hardwood closet rod, scrap ~1x3 boards or cut strips suffices. Frankly, these drivers in this style cab aren't going to be putting out much acoustic pressure, so I never bothered bracing them except for the baffle and driver to mass load it to the cab, but it can't hurt.

Chamfer out the backside of cutout at > 45 deg for this small a driver even with a single ~1.9 cm baffle thickness.

The bottom is normally a single thickness and the base to stabilize it is a separate double thickness piece normally made from a more massive material such as MDF, concrete, whatever you want, though if you want to leave out the extra panel and build in the base, that's fine too.

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- MLTL Enclosure for Fostex fe168sigma (old one)