Hi,

just a quick question: "Has anybody any experience or thoughts about using a torus/doughnut shape as an open baffle for a wide band/full range driver?

I only ask as the shape seems to me to offer two possible advantages:

1: a degree of waveguide type loading

2: the longest possible path from the front to the rear of the driver for any given baffle size.

(a torus having an overall width of 3 x the central hole diameter)

just a quick question: "Has anybody any experience or thoughts about using a torus/doughnut shape as an open baffle for a wide band/full range driver?

I only ask as the shape seems to me to offer two possible advantages:

1: a degree of waveguide type loading

2: the longest possible path from the front to the rear of the driver for any given baffle size.

(a torus having an overall width of 3 x the central hole diameter)

A pity that 'JohninCR' is no longer active in DIY audio [at least here] to tell you about his, but then again it's at least partly because after many speaker alignment experiments from the mundane to the bizarre, he decreed his rolled over dipole waveguide was the 'light at the end of the tunnel' or some-such, ‘disappearing’ shortly thereafter.

Best then to design a proper WG such as a 180 degree rolled over LeCleac’h than just accept a specific mathematical shape.

GM

Best then to design a proper WG such as a 180 degree rolled over LeCleac’h than just accept a specific mathematical shape.

GM

Greg - yes, John was lots of fun - bless him where / whatever he's up to

- maybe he created his own acoustic even horizon and is inside enjoying the hell out of his system, just can't report back 😀

- maybe he created his own acoustic even horizon and is inside enjoying the hell out of his system, just can't report back 😀

Put two LeCleac'h with roundovers back to back and you have a dipole torus speaker...

Isn't that what I suggested? 😉

GM

Hi,

of the two points that I mentioned the second maybe the more interesting, in that, for any open baffle the baffle width is important for the lower frequencies and the torus shape allows the longest path from front to back of any given baffle diameter. Also the dispersion from the driver will be very similar to that of a sphere initially.

To make a torus is considered difficult but I thought I would try the following method:

Take one wheelbarrow/cart tyre inner tube for a 10" wheel (they approximate a torus) remove the air valve from the valve stem and fill the inside of the tyre with expanding cavity foam (a little water needs to be put into the tube for the foam to cure) The expansion of the foam should fill the rubber inner tube to its full shape with some exiting throughout the valve stem. The volume of the torus can be easily calculated so enough foam is added!

When it has set one could trim the valve stem flush and leave the rubber, this would be hidden by the driver mount. It might be possible to remove the rubber tube by cutting through the rubber and peeling off. I'm not sure how well expanding foam sticks to rubber so it might be prudent to oil the interior of the rubber tube before filling with foam if the rubber is to be removed.

I thought of this method of making a close approximation of a torus some time ago and I will try it one day. It would not take long at all.

of the two points that I mentioned the second maybe the more interesting, in that, for any open baffle the baffle width is important for the lower frequencies and the torus shape allows the longest path from front to back of any given baffle diameter. Also the dispersion from the driver will be very similar to that of a sphere initially.

To make a torus is considered difficult but I thought I would try the following method:

Take one wheelbarrow/cart tyre inner tube for a 10" wheel (they approximate a torus) remove the air valve from the valve stem and fill the inside of the tyre with expanding cavity foam (a little water needs to be put into the tube for the foam to cure) The expansion of the foam should fill the rubber inner tube to its full shape with some exiting throughout the valve stem. The volume of the torus can be easily calculated so enough foam is added!

When it has set one could trim the valve stem flush and leave the rubber, this would be hidden by the driver mount. It might be possible to remove the rubber tube by cutting through the rubber and peeling off. I'm not sure how well expanding foam sticks to rubber so it might be prudent to oil the interior of the rubber tube before filling with foam if the rubber is to be removed.

I thought of this method of making a close approximation of a torus some time ago and I will try it one day. It would not take long at all.

Is that even possible in foam core? 😉

Yes, with gore shaped panels scored and curved and hot melt glued.

That seems a lot of work X. Jerryo didn't mention the main advantage which is elimination of diffraction. What I'm wondering is, although a torus would be the ideal, could a square equivalent be almost as effective?

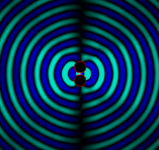

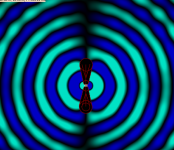

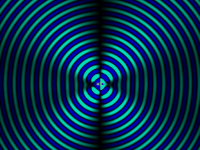

This gives an idea of how effective a torus can be, and with a simple waveguide it could be even better. I used this Ripple Tank Simulation and include the files if anyone want's to have a play with the simulations

Attachments

If the diameter is only 10in (and a circa 3.5in full range) you could glue up several layers of XPS or surfboard foam or even sheets of thick EVA and sculpt it. However, isn’t round torus going to produce equidistant paths and this will cause deep dips corresponding to the 1/2-wave length in the wrap around radial direction?

Assuming 10in outside dia torus and 3in width of toroidal body, pi x 3in is about 0.24m circumference front to back. That will give a deep destructive interface notch at 715Hz. It is deep because the entire perimeter has the same distance. A rectangular “toroid” double horn would have less of a deep notch since distances are varied. Same reason why rectangular flat baffles are superior to round baffles.

Assuming 10in outside dia torus and 3in width of toroidal body, pi x 3in is about 0.24m circumference front to back. That will give a deep destructive interface notch at 715Hz. It is deep because the entire perimeter has the same distance. A rectangular “toroid” double horn would have less of a deep notch since distances are varied. Same reason why rectangular flat baffles are superior to round baffles.

If you take a look at this recently resurrected thread it seems possible to spread the edge diffraction in space and time and have no on-axis nulls, not even the largest first one above the dipole peak This is either very wrong or I have still not understood diffraction from baffle edge

If this is the case in reality then a square shouldn't be any better or worse than a circle?

Here too https://www.diyaudio.com/forums/multi-way/361169-polar-response-frame-ob-speakers-6.html#post6370340

If this is the case in reality then a square shouldn't be any better or worse than a circle?

Here too https://www.diyaudio.com/forums/multi-way/361169-polar-response-frame-ob-speakers-6.html#post6370340

Last edited:

If the diameter is only 10in (and a circa 3.5in full range) you could glue up several layers of XPS or surfboard foam or even sheets of thick EVA and sculpt it. However, isn’t round torus going to produce equidistant paths and this will cause deep dips corresponding to the 1/2-wave length in the wrap around radial direction?

Assuming 10in outside dia torus and 3in width of toroidal body, pi x 3in is about 0.24m circumference front to back. That will give a deep destructive interface notch at 715Hz. It is deep because the entire perimeter has the same distance. A rectangular “toroid” double horn would have less of a deep notch since distances are varied. Same reason why rectangular flat baffles are superior to round baffles.

Hi,

Exactly, a round torus will have an equidistant path length between front and back of the driver and will lead to powerful baffle effects. As nice as the symmetric radiation of a nearly-round baffle is, these effects have to be taken into account. The baffle effects will be reduced considerably with the use of a petal baffle.

I had measurements from comparisons while building the flowers, but sadly these have been lost in a HD crash.

All the best

Mattes

Attachments

How do you mean? Allen showed a few here https://www.diyaudio.com/forums/multi-way/361169-polar-response-frame-ob-speakers-6.html#post6370340 It's the only sim I've ever used, and it has its limitations. It would be nice if somebody, who knew what they were doing, could use a better simulation

I doubt expanded foam would have much effect on low frequencies. It's a nice idea though and i wonder if something with more density could be injected in a similar way?To make a torus is considered difficult but I thought I would try the following method:

Take one wheelbarrow/cart tyre inner tube for a 10" wheel (they approximate a torus) remove the air valve from the valve stem and fill the inside of the tyre with expanding cavity foam (a little water needs to be put into the tube for the foam to cure) The expansion of the foam should fill the rubber inner tube to its full shape with some exiting throughout the valve stem. The volume of the torus can be easily calculated so enough foam is added!

How about something like this?

Tube Full-Round Donut, Stainless Steel | Pegasus Auto Racing Supplies

Tube Full-Round Donut, Stainless Steel | Pegasus Auto Racing Supplies

Wow 😀

Regards my previous post, foam may be good enough if felt is? Dipole wool carpet baffle experiment

Regards my previous post, foam may be good enough if felt is? Dipole wool carpet baffle experiment

- Home

- Loudspeakers

- Full Range

- Torus