Hi ! i have a line preamp solid state with a mains transformer soldered and tightly screwed to the preamp circuits pcb. The transformer is of the type in the picture below

I wonder if its vibrations could in some way cause any noise issues.

I am thinking about mechanically decoupling it in some way from the pcb but it is not that easy because it is designed to be soldered directly to the pcb.

I am thinking about soldering some wires to its terminal and mount it upside down with some rubber sheet/isolators under it

I have seen pictures of preamps where the active circuitry pcb is mounted on a frame on rubber feet ?

Have you ever thought of anything similar ?

Thanks a lot,

gino

An externally hosted image should be here but it was not working when we last tested it.

I wonder if its vibrations could in some way cause any noise issues.

I am thinking about mechanically decoupling it in some way from the pcb but it is not that easy because it is designed to be soldered directly to the pcb.

I am thinking about soldering some wires to its terminal and mount it upside down with some rubber sheet/isolators under it

I have seen pictures of preamps where the active circuitry pcb is mounted on a frame on rubber feet ?

Have you ever thought of anything similar ?

Thanks a lot,

gino

Attachments

Last edited:

Hi ! thanks for the kind and helpful reply. I see. Still there must be a reason why the same manufacturer for their top of the line preamp has decided for an external power supply housed in a separated chassis

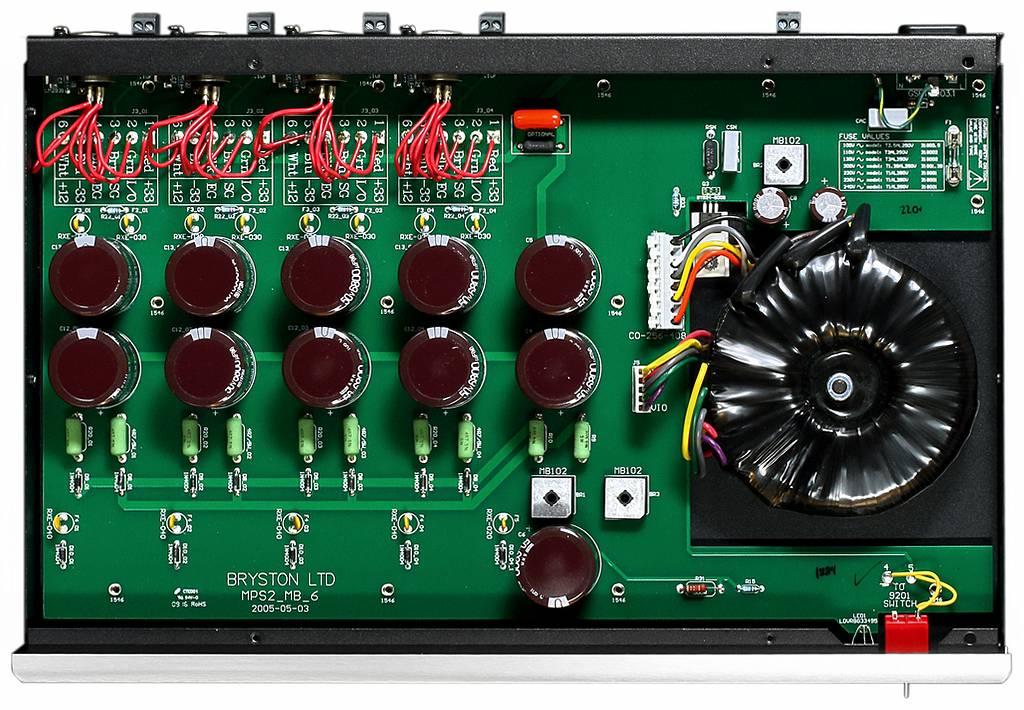

BP-26 – Bryston

And this is supposed to be their very best preamp ever from what i read from the press.

Therefore i wonder what is the rationale behind this design choice. And they are not alone at doing this.

Almost all high end manufacturers use external power supplies for their TOTL preamps. Instead this is very rare for power amps and integrated.

Only to charge more ? i doubt especially considering the seriousness of the brands

I agree that we are not dealing with tubes that for their nature could pick up noise more easily. Still ...

However i notice also that for the high power supply they have decided for a toroidal transformer ... that is what i would like to do in the end.

BP-26 – Bryston

And this is supposed to be their very best preamp ever from what i read from the press.

Therefore i wonder what is the rationale behind this design choice. And they are not alone at doing this.

Almost all high end manufacturers use external power supplies for their TOTL preamps. Instead this is very rare for power amps and integrated.

Only to charge more ? i doubt especially considering the seriousness of the brands

I agree that we are not dealing with tubes that for their nature could pick up noise more easily. Still ...

However i notice also that for the high power supply they have decided for a toroidal transformer ... that is what i would like to do in the end.

Last edited:

I wonder if its vibrations could in some way cause any noise issues.

I would not call them "noise issues" but yes, it is pretty easy to hear how a transformer is mounted, whether it sits on top of wood, plastic, metal, rubber.

All my preamps have external PS but this is also problematic because the dc carrying wires appear even more audible than the AC mains cables. It's a minefield

Some companies are making good business out of upgrading the DC wires for Pass preamps per example.

Thanks ! i see your point perfectlyMy guess is that they choose external psu is to reduce hf radiation to sensitive circuatry, but good shielding and layout is also a way to go

Do you have a *real* problem to solve or is it just anxiety?I wonder if its vibrations could in some way cause any noise issues.

yes, so? .........I have seen pictures of preamps where the active circuitry pcb is mounted on a frame on rubber feet ?

Preamps by definition are sensitive, anything causing less noise is welcome.Therefore i wonder what is the rationale behind this design choice. And they are not alone at doing this.

Almost all high end manufacturers use external power supplies for their TOTL preamps. Instead this is very rare for power amps and integrated.

But design is made by the designer, in this case a very good one.

Doubt you can do better than him.

And preamps use little power, so no big deal in feeding it DC through long wires (coming from another box).

Power amps on the contrary are large, heavy, and by definition power hungry, good design choice is to have the PSU as close as possible, 99.999% of the time meaning inside the same chassis.

Only to charge more ? i doubt especially considering the seriousness of the brands

Toroids are efficient, usually have better regulation than equivalent EI types and are flatter, which makes for more elegant chassis.However i notice also that for the high power supply they have decided for a toroidal transformer ... that is what i would like to do in the end.

Doubly important if you use rack type cabinets.

Not necessary in a preamp where even an EI transformer is small enough.

WHY would you want to add a toroid where the original EI type works flawlessly is beyond me.

I would not call them "noise issues" but yes, it is pretty easy to hear how a transformer is mounted, whether it sits on top of wood, plastic, metal, rubber. All my preamps have external PS but this is also problematic because the dc carrying wires appear even more audible than the AC mains cables. It's a minefield

Hi ! thank you very much indeed for your great advice. I did not think about it really as long as decent wire sections are used. Moreover they have to carry no more than some tenth of Ampere in steady situation. I guess all good preamps are operating in class A and so the current draw (surge aside) should be constant ?

This also is very interesting. It looks like only a design issue. A good dc umbilical can be done in the end. I will try to get some information because i am quite settled on this project. Starting with this old preamp i would like in the future select a nice sounding solid state line stage using +/-24VDC as power. I prefer solid state circuits for potential lower distortion and higher current delivery. It will be a retirement long project. I still think that the preamp is very important for the overall result. I have always been surprised reading reviews of commercial units that the power amps come out better sounding and with the line preamps being the weak link. Strange isn't it ? especially with solid state preamp. The ones good sounding are rare and usually very expensive. I wonder why.Some companies are making good business out of upgrading the DC wires for Pass preamps per example

Ok if they have a Penny&Giles or a TKD pot inside i understand why they are expensive

Thanks a lot again.

gino

Do you have a *real* problem to solve or is it just anxiety ?

Hi ! actually i hear some noise ... but it could be a ground loop issue. It is an unbalanced preamp. Honestly i lost the upper lid and i have to do something about it. I cannot leave the parts inside exposed

A new case at least ... so being in the mod mode i was thinking to mod it further.

i was mixing things. Usually this happens only with tubes. No issue with solid state and i would like to stick with solid state.yes, so? .........

Great ! i have my eyes already on a cheap lab dual power supplyPreamps by definition are sensitive, anything causing less noise is welcome. But design is made by the designer, in this case a very good one.

Doubt you can do better than him. And preamps use little power, so no big deal in feeding it DC through long wires (coming from another box).

very very important. Thanks for the advicePower amps on the contrary are large, heavy, and by definition power hungry, good design choice is to have the PSU as close as possible, 99.999% of the time meaning inside the same chassis.

I see. A form factor issue. Yes they have slim front panels. And so low profile parts inside are needed.Toroids are efficient, usually have better regulation than equivalent EI types and are flatter, which makes for more elegant chassis.

Doubly important if you use rack type cabinets.

Not necessary in a preamp where even an EI transformer is small enough.

WHY would you want to add a toroid where the original EI type works flawlessly is beyond me

the main thing i do not like about it is that is soldered directly to the same boards where preamp circuitry is. I am scared to touch it to feel if it vibrates or not. I do not have specs about its regulation and VA ... there is a copper foil around it hiding brand and model.

It looks like an Hammond transformer https://www.razzmatazz.it/5238/hammond-229c40.jpg

It could be a 30VA thing max.

I have already extract the balance pot because i read that it can introduce some crosstalk ... i hate balance and even more tone controls. They should be made illegal.

Thanks a lot again, gino

Last edited:

I guess all good preamps are operating in class A and so the current draw (surge aside) should be constant ?

Absolutely.

The following observations relate only to my own preamp.

The remote PS houses a very large power transformer, several chokes, a mercury rectifier for B+ and a vacuum rectifier for the negative tail voltage, capacitors and rectifiers for the heaters. It sits on the floor. Two meters away is the actual preamp which houses the local regulation - Salas 1.3 for B+ and 3-terminal regulators for the valves. The topology is balanced differential with an output transformer. Little doubt that the current consumption is fixed by the Sallas CCS. 6 wires are required altogether and for convenience the termination uses cold war military connectors.

For a couple of years i used generic PVC insulated wires until i built a second preamp for the bedroom which used thick magnet wire instead. The difference in sound between the DC carrying PVC wires vs the polyethylene isolated magnet wire was profound and this prompted me to try OCC wire. Initially teflon isolated and eventually, despite the painful procedure, again polyethylene isolated. Each stage brought some improvement but nothing like the initial comparison of multicore PVC copper vs single core polyethylene tubed copper.

Absolutely.

Good ! and thank you very much. This should simplify things because if the draw is constant ... i like it better i do not know why And most of people say that class A is good by definition in general.

The following observations relate only to my own preamp.

The remote PS houses a very large power transformer, several chokes, a mercury rectifier for B+ and a vacuum rectifier for the negative tail voltage, capacitors and rectifiers for the heaters. It sits on the floor. Two meters away is the actual preamp which houses the local regulation - Salas 1.3 for B+ and 3-terminal regulators for the valves. The topology is balanced differential with an output transformer. Little doubt that the current consumption is fixed by the Sallas CCS. 6 wires are required altogether and for convenience the termination uses cold war military connectors.

For a couple of years i used generic PVC insulated wires until i built a second preamp for the bedroom which used thick magnet wire instead. The difference in sound between the DC carrying PVC wires vs the polyethylene isolated magnet wire was profound and this prompted me to try OCC wire. Initially teflon isolated and eventually, despite the painful procedure, again polyethylene isolated. Each stage brought some improvement but nothing like the initial comparison of multicore PVC copper vs single core polyethylene tubed copper.

Wow ! i know nothing on tubes but this sounds like a really impressive unit indeed... Congratulations ! and i am sure its sound should be quite spectacular. I agree with people who think that tubes always sound at least very musical and in the better designs truly spectacular ... but maybe in the future when i will have more time to dedicate to this very beautiful hobby.

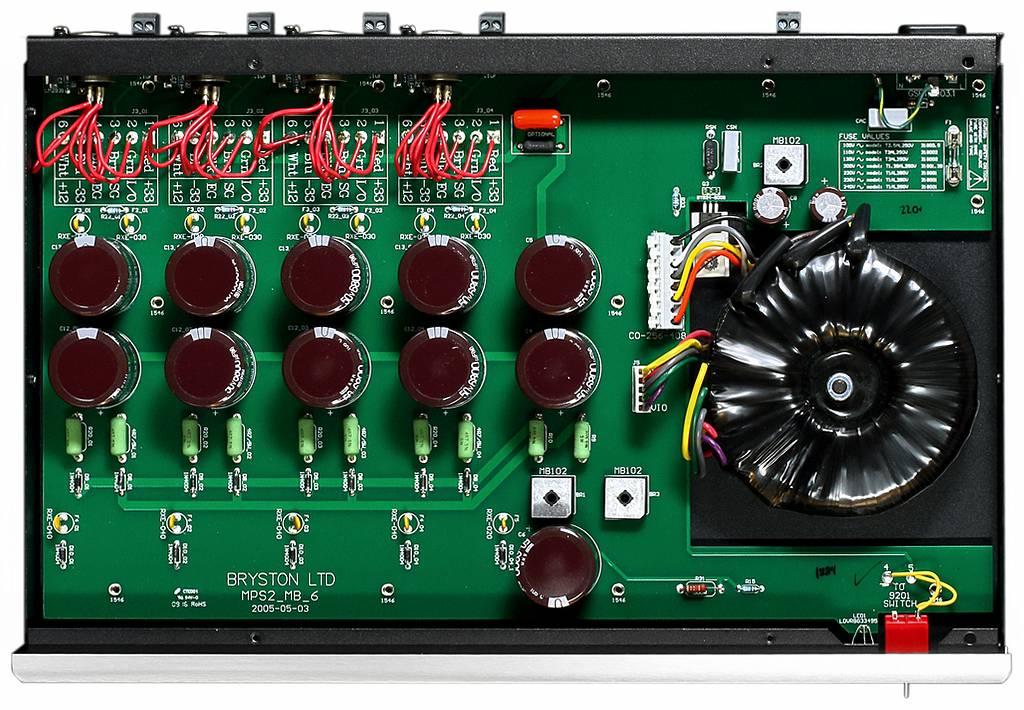

And just as preamp ... line preamp. Moreover very interesting the magnet wires used as DC umbilical. I guess you use them twisted together ? i will need a tre wires cable and i wonder if something like the Kimber solution could work also for a DC umbilical using magnet wires

I am a little worried about their stiffness that could put some stress on the soldered joints ? personally i like very flexible power cords like the ones used for extension the orange type if you know it.

Again if the current draw from the circuit is constant as long as the cable resistance and maybe impedance are low there should not be big issues i guess. But i am not sure.

Stiffness is a huge issue with thick (1mm+) magnet wire. A special attention is required at the points of termination for stress relief and one of my cables ended up having short lengths of multistrand at the ends.

Kimber do not use solid core wires and a similar geometry is pretty much impossible to emulate with solid cores. Otoh what Kimber uses is not a typical multistrand and is much closer in sound to a solid core but with the added convenience of being a lot more pliable and twistable. It would be great if similar wire to Kimber existed, only made out of OCC copper.

Kimber do not use solid core wires and a similar geometry is pretty much impossible to emulate with solid cores. Otoh what Kimber uses is not a typical multistrand and is much closer in sound to a solid core but with the added convenience of being a lot more pliable and twistable. It would be great if similar wire to Kimber existed, only made out of OCC copper.

Stiffness is a huge issue with thick (1mm+) magnet wire. A special attention is required at the points of termination for stress relief and one of my cables ended up having short lengths of multistrand at the ends.

Hi ! it sounds too difficult to me. A friend of mine showed me some litz wires. But they are tricky to solder ... he was using a kind of melting pot but not very healthy process i am afraid. In that way you will have many solid core wires individually isolated. Some people say that they sound very good.

I see. The fact that there are special cords for preamps means that they are critical indeed. I wonder which kind of wires they use. It is not clear to me which parameters must be kept under control ... i guess resistance and inductance. Instead some capacitance could be even beneficial for some filtering effects on high Hz mains noise ? first the regulation ... than i will look about different cords. It is a medium to long term project. In my opinion very good preamps are more rare than power amps. I really do not know why ...Kimber do not use solid core wires and a similar geometry is pretty much impossible to emulate with solid cores. Otoh what Kimber uses is not a typical multistrand and is much closer in sound to a solid core but with the added convenience of being a lot more pliable and twistable. It would be great if similar wire to Kimber existed, only made out of OCC copper

Hi !

I wonder if its vibrations could in some way cause any noise issues.

gino

The vibrations, do you hear them or feel them?

All EI transformers have some Vibrations.. As soon you can hear them, then I would check the Circuit.

What should you check? Check the BIG CAPS and Bridge anything which gives Stress to the transformer that it hauls up in a not normal way.

But don't go and rip your PSU in Pieces.. It looks to me rather old..

[/quote]I am thinking about soldering some wires to its terminal and mount it upside down with some rubber sheet/isolators under it[/END QUOTE]

Ok I see at the Switch that this Switch was build in the 1989. First half of the year.. that's more than 30 years.

The Transformer itself was Checked in 1993= 27years. It's absolutely normal that it vibrates a little bit..

To get rid of to big part of Vibrations, you can do following, and if you make this with the necessary care, then vibrations sure will be removed by a good percentage. and its almost free, no need to invest a lot of money.

1.Get Electrical Lacquer say 0.5lt. and also 0.5l of the necessary thinner. Both of this are only a few Euros.. MAKE sure that you get HEAT RESISTANT, at least 70degrees Celsius Lacquer. and that the LACQUER is not NITRO but Synthetic resin. This will stick longer and also take longer to dry. Nitro will degrade faster. Bejer LACQUER have this in 1lt cans or so.

2.De-solder all Wires from the transformer to the circuit

3.Make sure you have noted down which wire goes to what Soldering point on the board, of use your XIAOMI to take some pictures..

4. Now unscrew the Transformer

5. Take a big enough Bowl or something which the Transformer fits in, and fill it to 1 quarter with lacquer an then use thinner to make it just good fluid so that not drops from but runs instead..

6. Place the Transformer in there for say an hour or two making sure that you turn it to all sides after 10 - 15 Minutes so the the lacquer can get into the transformer to all air-gaps there might be.

7. Use a long wire and stick this one through the screw holes and hang the transformer to dry, this will take some time and it depends on the air-gaps which were inside.. but I can assure you that it takes at least 24 - 48 hours to fully dry out.

8.When dry and finished then place it back in the BOX. Make sure that all wires which may got some Lacquer are cleaned of otherwise it will be hard to solder them back.

9. And yes if you can get some hard rubber feet, and drill a hole inside. Stick a Aluminum pipe with diameter of the applying screw through the hole and cut this shorter than the thickness of the HARD RUBBER.

EXAMPLE: if the rubber is 5mm thick then the pipe only 3mm. this is to prevent hitting either the transformer nor the Case with that Pipe. it gives stability and also reduces vibration at the same time..

I'm sure that this procedure will remove Vibrations.

But you can have this more easy.. Get a new Toroidal transformer with the same Values..

I would take a look at those 4700uf /50 Volts caps. I see that the hat of the lower of them *in the picture* is bend a little bit, this is a sign of degrading.

If you go and work on that transformer then also exchange both Caps.. it will give less stress on the Rectifier and this will also reduce Vibrations on that Transformer. Otherwise use a Rubber mat underneath the Case, this also will reduce Vibrations, not of the PSU but on whatever it is placed on.

My 5 cents to this Issue.

Regards Chris

In my opinion very good preamps are more rare than power amps.

In full agreement here. Imho the high end marketplace is littered with mediocre sounding preamps.

The vibrations, do you hear them or feel them ?

All EI transformers have some Vibrations.. As soon you can hear them, then I would check the Circuit.

Hi ! let me put my words in another way. I have this old Bryston preamp ... i cannot find the lid anymore. To use it practically i have to replace the case at least. So i am thinking to do something to the circuit.

Looking at the TOTL preamps from Bryston i see that they have an external power supply separated by the circuits board.

So the idea is to build a two chassis thing extracting the present transformer and put it in the other case ... or even add another regulation stage upstream the original one. A sane move ? maybe not. Maybe yes. That would leave distortion fugures the same but eventually could decrease the already low noise.

the regulation stage is just two fixed single chip +/-24V regulators ... nothing high end i guessWhat should you check? Check the BIG CAPS and Bridge anything which gives Stress to the transformer that it hauls up in a not normal way. But don't go and rip your PSU in Pieces.. It looks to me rather old..

I should measure the noise first you are right ... i will look for suggestion in the forum I would like to use the laptop to measure it

I understand i need a usb sound card with very low own noise and a SW that i have already (i have used Arta)

Problem is that USB sound cards can be very noisy by themselves.

And maybe a noise spectrum could be even more telling about noise distribution ? from a review i understand that the distortion instead is quite low. No problem with the amp circuit ...

I am thinking about soldering some wires to its terminal and mount it upside down with some rubber sheet/isolators under it

Ok I see at the Switch that this Switch was build in the 1989. First half of the year.. that's more than 30 years. The Transformer itself was Checked in 1993= 27years. It's absolutely normal that it vibrates a little bit..

To get rid of to big part of Vibrations, you can do following, and if you make this with the necessary care, then vibrations sure will be removed by a good percentage. and its almost free, no need to invest a lot of money.

1. Get Electrical Lacquer say 0.5lt. and also 0.5l of the necessary thinner. Both of this are only a few Euros.. MAKE sure that you get HEAT RESISTANT, at least 70degrees Celsius Lacquer. and that the LACQUER is not NITRO but Synthetic resin. This will stick longer and also take longer to dry. Nitro will degrade faster. Bejer LACQUER have this in 1lt cans or so.

2. De-solder all Wires from the transformer to the circuit

3. Make sure you have noted down which wire goes to what Soldering point on the board, of use your XIAOMI to take some pictures..

4. Now unscrew the Transformer

5. Take a big enough Bowl or something which the Transformer fits in, and fill it to 1 quarter with lacquer an then use thinner to make it just good fluid so that not drops from but runs instead..

6. Place the Transformer in there for say an hour or two making sure that you turn it to all sides after 10 - 15 Minutes so the the lacquer can get into the transformer to all air-gaps there might be.

7. Use a long wire and stick this one through the screw holes and hang the transformer to dry, this will take some time and it depends on the air-gaps which were inside.. but I can assure you that it takes at least 24 - 48 hours to fully dry out.

8. When dry and finished then place it back in the BOX. Make sure that all wires which may got some Lacquer are cleaned of otherwise it will be hard to solder them back.

9. And yes if you can get some hard rubber feet, and drill a hole inside. Stick a Aluminum pipe with diameter of the applying screw through the hole and cut this shorter than the thickness of the HARD RUBBER.

EXAMPLE: if the rubber is 5mm thick then the pipe only 3mm. this is to prevent hitting either the transformer nor the Case with that Pipe. it gives stability and also reduces vibration at the same time..

I'm sure that this procedure will remove Vibrations.

Wow ! thank you very much for the extreme detailed instructions. I see a very challenging task for me. I sincerely do not know if i am up to it.

Thinking more about the all issues, before touch anything i should maybe measure the actual noise coming out the preamp ?

Moreover how much of this noise could be vibes generated instead of the result of a improvable regulations ? circuit aside i mean for instance the caps you mention maybe too old to be perfectly working. Maybe just replacing them can suppress some noise ?

I read an article by John Curl about preamps. He advises to use split bobbins type ones in preamps power supplies. Like EI type or R-Core type.But you can have this more easy.. Get a new Toroidal transformer with the same Values ...

(actually i am thinking about the R-core type) He says they can suppress better high Hz noise from the mains, where fixed regulators are said to provide poor performance.

Unfortunately i cannot find graph showing the PSRR in the audio range for any 24V part ... strange. Noise suppression should be clearly showed i guess in a graph. A good graph can show clearly what is going on.

I would take a look at those 4700uf /50 Volts caps. I see that the hat of the lower of them *in the picture* is bend a little bit, this is a sign of degrading. If you go and work on that transformer then also exchange both Caps ... it will give less stress on the Rectifier and this will also reduce Vibrations on that Transformer. Otherwise use a Rubber mat underneath the Case, this also will reduce Vibrations, not of the PSU but on whatever it is placed on. My 5 cents to this Issue. Regards Chris

for sure caps they will go. I like Nichicon ones a lot. I have seen also Roederstein parts used in very high end units. I will check dimensions.

In case i remove the transformer and place it externally there will be space to add some more caps. I like the approach Ps Audio follow in their older preamps ... like the 5.0 and 5.5 models. They have only the transformer put in an external box and from the rectifiers down all in the same box with circuits. There must be some considerations behind this design choice i guess.

In full agreement here. Imho the high end marketplace is littered with mediocre sounding preamps.

Hi thanks a lot for the important confirmation. I am focusing my attention only on line preamps these days. I have already a decent power amp but still struggling with preamps ... no one convinces me completely. And most of them have too high gain. I guess all this search will take time.

Kind regards, gino

Last edited:

Is that a SIGNAL cable?

Almost choked on my coffee.

Have you heard about the wonderful new invention, the SHIELDED cable?

Based on the latest works of that controversial young guy, Faraday.

Is that a SIGNAL cable?

Almost choked on my coffee.

Have you heard about the wonderful new invention, the SHIELDED cable?

Based on the latest works of that controversial young guy, Faraday.

Hi ! i see your point. This was the cheap version ... there was another one with silver wires. I did not understand the reason for not using a shield

@ginetto61

KimberKable is around for about 30 years by now..

from my point of view.. to expensive..

The way these are braided, constructs the shield.. Still to expensive..

Invest in good Hardware is the better choice. I have seen People using Arm-thick Loudspeaker Cables in their houses, and when they like to clean the carpet then need a Crane to lift the cables.. but does it increase the Quality of sound more than 0.0001%?

I doubt that.

A friend of mine had the Electricity Company pulling a Cable from Mains CUT OUT to his Music Room with a diameter of 3X 25mm Copper for AC.. and Special Cut Out..

He used 6 Rowen CLASS A Mono Blocks and more that fancy things.. Speakers were also Rowen. Speaker Cables at least 25mm in diameter.

Asked him, If I could listen to the system, he replied " but of course, I will let you know as soon I switch the system on next time, it needs to get warm for 4days at Idle.."

I'm still waiting listen to that system, but this will not happen anymore, my friend was killed in a Car Accident .. the following year.. Sad but true story.

It's all about what you believe and in the end it's all about the same..

OK. Good cable, with -OF- Oxygen Free - COPPER and good shielded may also a carbon shield extra and good connected eventually gold-plated Jacks are sure to be better than any standard Cable. And after the input in the Pre-amp or Line-drive, or Power amp there the cable has no more influence anymore.. Cause many Manufacturers running thin wires to the PCB of the Amp. And not seldom stiff wires instead of threaded wires..

So what you gain before the AMP you will loose after it's back-plate..

But this everyone's own choice..

The stiffness of the cables also putting lots of unnecessary force on the Jacks, both sides, just to wonder why after a time of use the cable and Jacks have failing contacts, after the system needs to be moved to clean or whatever reason it might be..

Tried to explain this like I have seen in my long way with high end..

Greetings

Chris

KimberKable is around for about 30 years by now..

from my point of view.. to expensive..

The way these are braided, constructs the shield.. Still to expensive..

Invest in good Hardware is the better choice. I have seen People using Arm-thick Loudspeaker Cables in their houses, and when they like to clean the carpet then need a Crane to lift the cables.. but does it increase the Quality of sound more than 0.0001%?

I doubt that.

A friend of mine had the Electricity Company pulling a Cable from Mains CUT OUT to his Music Room with a diameter of 3X 25mm Copper for AC.. and Special Cut Out..

He used 6 Rowen CLASS A Mono Blocks and more that fancy things.. Speakers were also Rowen. Speaker Cables at least 25mm in diameter.

Asked him, If I could listen to the system, he replied " but of course, I will let you know as soon I switch the system on next time, it needs to get warm for 4days at Idle.."

I'm still waiting listen to that system, but this will not happen anymore, my friend was killed in a Car Accident .. the following year.. Sad but true story.

It's all about what you believe and in the end it's all about the same..

OK. Good cable, with -OF- Oxygen Free - COPPER and good shielded may also a carbon shield extra and good connected eventually gold-plated Jacks are sure to be better than any standard Cable. And after the input in the Pre-amp or Line-drive, or Power amp there the cable has no more influence anymore.. Cause many Manufacturers running thin wires to the PCB of the Amp. And not seldom stiff wires instead of threaded wires..

So what you gain before the AMP you will loose after it's back-plate..

But this everyone's own choice..

The stiffness of the cables also putting lots of unnecessary force on the Jacks, both sides, just to wonder why after a time of use the cable and Jacks have failing contacts, after the system needs to be moved to clean or whatever reason it might be..

Tried to explain this like I have seen in my long way with high end..

Greetings

Chris

Last edited:

@ginetto61

KimberKable is around for about 30 years by now.. from my point of view.. to expensive.. The way these are braided, constructs the shield.. Still to expensive..

Hi ! thanks for the kind and helpful advice. I think they are only for line level signals not phono. The lack of a shield is strange. I do not know what a shield can do wrong.

Invest in good Hardware is the better choice. I have seen People using Arm-thick Loudspeaker Cables in their houses, and when they like to clean the carpet then need a Crane to lift the cables.. but does it increase the Quality of sound more than 0.0001%?

I doubt that.

A friend of mine had the Electricity Company pulling a Cable from Mains CUT OUT to his Music Room with a diameter of 3X 25mm Copper for AC.. and Special Cut Out..

He used 6 Rowen CLASS A Mono Blocks and more that fancy things.. Speakers were also Rowen. Speaker Cables at least 25mm in diameter.

Asked him, If I could listen to the system, he replied " but of course, I will let you know as soon I switch the system on next time, it needs to get warm for 4days at Idle.."

thanks for the very useful advice. I have a similar friend who spent a small fortune on fancy cables.

I'm still waiting listen to that system, but this will not happen anymore, my friend was killed in a Car Accident .. the following year.. Sad but true story. It's all about what you believe and in the end it's all about the same..

really sorry to hear this.

this i understand. What i do not understand why not to put thicker wires where the current is high ? like the wires going to the speaker outs ?OK. Good cable, with -OF- Oxygen Free - COPPER and good shielded may also a carbon shield extra and good connected eventually gold-plated Jacks are sure to be better than any standard Cable.

And after the input in the Pre-amp or Line-drive, or Power amp there the cable has no more influence anymore.. Cause many Manufacturers running thin wires to the PCB of the Amp. And not seldom stiff wires instead of threaded wires..

So what you gain before the AMP you will loose after it's back-plate..

but also on the voltage lines feeding the output devices ...

Another strange thing is that looking at a power bjt pins are big the same

It would be also easier to identify them ... small section pin Base, medium section pin Collector and bigger section pin Emitter ? in accordance with the current likely to flow through i mean ....

i agree completely on this point. I do not like rigid connections at all.But this everyone's own choice..

The stiffness of the cables also putting lots of unnecessary force on the Jacks, both sides, just to wonder why after a time of use the cable and Jacks have failing contacts, after the system needs to be moved to clean or whatever reason it might be..

Tried to explain this like I have seen in my long way with high end..

Greetings

Chris

The above mentioned friend at certain point used strange signal cable that looked like pipes ... they were solid core copper. I do not remember the brand. They were bent to be put in place. Very strange cables ... but he liked the sound a lot.

I was doing some cables with a cheap mini coaxial bulk cable and used them also for rca digital

Thanks a lot again, gino

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Mains transformer vibrations and circuits