Got a reply from Varathane tech support.

They say that Varathane 1 step poly and stain is designed for wood and wood absorbs the stain. the primer layer on my MDF is preventing this process, resulting in stain accumulating.

Only 1 way to find out. I will try it on bare piece of MDF.

regards

Prasi

They say that Varathane 1 step poly and stain is designed for wood and wood absorbs the stain. the primer layer on my MDF is preventing this process, resulting in stain accumulating.

Only 1 way to find out. I will try it on bare piece of MDF.

regards

Prasi

Prasi,

Maybe OT since you have started building the cabinets with MDF. Quality plywood is available in India - I recall using Indian made marine ply - it was 19mm 11 layer "garjan plywood", probably made by "Green Ply" - very heavy and robust. Not 100% void free, but not that many voids... Marine ply is usually 2-2.5x the price of standard ply; you might find decent 8-11 layer 18-19mm plywood even in standard varieties.

For wood veneer there is a very thin type which is <1 mm thick, a bit like paper. There is an another type which is very thin plywood and ~2-2.5 mm thick. I have used both and both work fine. You can stick the veneer to your speaker box using contact adhesives or wood glues like aliphatic resin or PVA. With wood veneer you will also have to stain and finish them - a furniture painter might be able to help with that if you go that route.

Hope what you're trying out works satisfactorily. Keep us posted on your progress.

Maybe OT since you have started building the cabinets with MDF. Quality plywood is available in India - I recall using Indian made marine ply - it was 19mm 11 layer "garjan plywood", probably made by "Green Ply" - very heavy and robust. Not 100% void free, but not that many voids... Marine ply is usually 2-2.5x the price of standard ply; you might find decent 8-11 layer 18-19mm plywood even in standard varieties.

For wood veneer there is a very thin type which is <1 mm thick, a bit like paper. There is an another type which is very thin plywood and ~2-2.5 mm thick. I have used both and both work fine. You can stick the veneer to your speaker box using contact adhesives or wood glues like aliphatic resin or PVA. With wood veneer you will also have to stain and finish them - a furniture painter might be able to help with that if you go that route.

Hope what you're trying out works satisfactorily. Keep us posted on your progress.

Last edited:

Now as the boxes are already built, I must salvage whats available.

Definitely, and that should be possible too with your hard work and with some help from the forum.

If the painting experiments do not give you satisfactory results, something like this can help you dress up the boxes:

Decorative Veneer Plywood, Thickness: 3mm | ID: 2026807473

You can give them a call to check pricing and availability.

I have used truck bed liner rolled on speakers and it gives a hard finish that will not telegraph joints. Doesn't look much like wood.  The last speakers that I built used truck bed liner on five sides and varnished wood for the front panel. Came out quite nice. There are versions of it that you can tint if you don't want black or white.

The last speakers that I built used truck bed liner on five sides and varnished wood for the front panel. Came out quite nice. There are versions of it that you can tint if you don't want black or white.

It is Duratex. I have used Duratex and stuff marketed as truck bed liner and haven't noticed a difference. Do not buy water based truck bed liner. It is definitely inferior. Roll 2 coats on and get down to listening. I have no patience when it comes to finishing, so the combination of Duratex on 5 sides and wood finish (varnish/shellac/oil/wax/whatever) on the front baffle works for me.

I have no patience when it comes to finishing, so the combination of Duratex on 5 sides and wood finish (varnish/shellac/oil/wax/whatever) on the front baffle works for me.

+1 I resemble this remark! I went you one better, matte black spray bomb'd only the parts of the speaker system I could see through full size grills.

GM

OK, we all agree we are lazy and MDF is a bear to finish for us.

With any surface except MDF, there are lots of pretty easy ways to paint, varnish, or stain without too much effort. I rather like real wood. Can't we buy "one-side-good" MDF or wood-veneer covered or even plastic-veneer covered?

B.

With any surface except MDF, there are lots of pretty easy ways to paint, varnish, or stain without too much effort. I rather like real wood. Can't we buy "one-side-good" MDF or wood-veneer covered or even plastic-veneer covered?

B.

In pre-cut lengths, i.e. premium shelving, etc., ditto HDF and have recommended them on occasion for smaller, higher Qt systems. Ikea has been a popular outlet in recent years.

Don't know about nowadays, but use to be able to buy large sheets from local cabinet makers, though at least in my locale they would only do whatever minimum order their supplier demanded or charged you that price even if only buying a single sheet.

GM

Don't know about nowadays, but use to be able to buy large sheets from local cabinet makers, though at least in my locale they would only do whatever minimum order their supplier demanded or charged you that price even if only buying a single sheet.

GM

They lay-up veneer on mdf. Actually it's a preferred core. Graining mdf is an art. I worked for an Italian millwork shop in Chicago back in the day. They had a guy in the finishing department that was a true artist. Another guy and myself got pulled off a job in the Loop and were sent out to a residence in Lake Forest. We met the shop truck with a "Greek" style table in the back. The kid driving the truck jumped up in back to grab one of the "marble" pedestals. I yelled to him to wait so I could give him a hand (avoid a hernia or blown disc). "No, I got it." he picked it up like nothing and humped it to the tail. I'd swear it was marble even right up to my face. The whole table and both pedestals where done. Plaster, primer, base coat, feather graining, top coat, just unbelievably beautiful work.

Last edited:

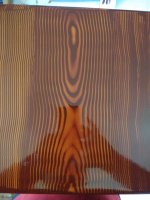

Finally, after almost 2 months of struggle, I am able to get the desired wood finish on the speakers. Here is a WIP pics. Looks good isnt it? Its with enamel paint.

It took many many trials with various paints, tools, methods.

I had lots of trouble with orange peal, and then dust.

For the orange peal, sanding of primed surface plays very important role. Atleast 3-4 layers of primer sanded till you get a very smooth surface without the peal.

For dust, a method i am successful at is as follows.

After the top coat, till the paint dries, many many dust particles will settle down on the surface.

Use 2000 grit sand paper with wet sanding, to get rid of those, to the extent possible without affecting the finish.

Then prepare a very very thinned paint of your top coat and put a thin layer of it with a rag. This will dry pretty quick, before the dust has a chance to settle. Voila, you get a very smooth surface, without loosing the texture.

regards

Prasi

It took many many trials with various paints, tools, methods.

I had lots of trouble with orange peal, and then dust.

For the orange peal, sanding of primed surface plays very important role. Atleast 3-4 layers of primer sanded till you get a very smooth surface without the peal.

For dust, a method i am successful at is as follows.

After the top coat, till the paint dries, many many dust particles will settle down on the surface.

Use 2000 grit sand paper with wet sanding, to get rid of those, to the extent possible without affecting the finish.

Then prepare a very very thinned paint of your top coat and put a thin layer of it with a rag. This will dry pretty quick, before the dust has a chance to settle. Voila, you get a very smooth surface, without loosing the texture.

regards

Prasi

Attachments

Last edited:

I used to cover MDF with the thinnest triplex I could get. Usually 3mm and normally it is used for doors. Pro: it is real wood and easier to handle than veneer. Con: either the corners are not very beautiful (exposed end grain) or you have to very carefully make some kind of lap joint.

Finally you could use plastic laminate with wood grain surface structure. Not the glossy type!

Finally you could use plastic laminate with wood grain surface structure. Not the glossy type!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- MDF speaker finishing techniques