Hi, I have recently fitted a new DC motor, speed controller, and PSU (cheap wall wart job I had lying around) to my DIY effort turntable and I have ended up with a very annoying very high pitch noise coming through the speakers as soon as I switch it on. The sort of high pitch that not everyone can hear, my wife can't. It doesn't change with motor speed, and it doesn't go away when a record is playing. I can filter it out using the high filter switch on my amp (1970s vintage with a low and high filter presumably for turntable issues!) But then I loose some of the top notes on the records and they sound a bit depressed.

Anyone experienced this? Or can point me in the direction of a solution? Or at least the location of the problem?

Cheers

Ben

Anyone experienced this? Or can point me in the direction of a solution? Or at least the location of the problem?

Cheers

Ben

I include some photos of various parts of the turntable:

1. general view

2. audio connection side

3. motor from above, blue wire taped to the motor is earthing the motor case to the ground terminal on the back - I was experimenting with earthing an this arrangement removed all back ground noise except the high pitch squeal.

4. the PSU

5. the motor, speed controller and power cables from below. I have soldered 1 uf capacitors between each motor terminal and its case to try and remove the high pitch noise. It doesn't work!

Also, if I hold the motor still, the noise is still present.

So I think it points towards either the speed controller or the PSU - I don't think its motor noise.

Is there a cheap way of proving the PSU is the problem - i don't really want to buy a linear PSU only to find it wasn't that.

Ben

1. general view

2. audio connection side

3. motor from above, blue wire taped to the motor is earthing the motor case to the ground terminal on the back - I was experimenting with earthing an this arrangement removed all back ground noise except the high pitch squeal.

4. the PSU

5. the motor, speed controller and power cables from below. I have soldered 1 uf capacitors between each motor terminal and its case to try and remove the high pitch noise. It doesn't work!

Also, if I hold the motor still, the noise is still present.

So I think it points towards either the speed controller or the PSU - I don't think its motor noise.

Is there a cheap way of proving the PSU is the problem - i don't really want to buy a linear PSU only to find it wasn't that.

Ben

Attachments

Is it a BLDC motor? Does the PSU use PWM for the output.

A lot of the cheap controllers use PWM at 10kHz to power these motors and it can radiate noise into your system.

It is not limited to cheap controllers. The VPI HW40 uses a $570 controller and it also uses 10kHz PWM and can radiate up to 180mVPP of noise into 47kΩ.

A lot of the cheap controllers use PWM at 10kHz to power these motors and it can radiate noise into your system.

It is not limited to cheap controllers. The VPI HW40 uses a $570 controller and it also uses 10kHz PWM and can radiate up to 180mVPP of noise into 47kΩ.

As Your arm isn't all metal, I would wrap some braid on the cables for shielding and would connect them to system ground.

I also see a lot of cable hanging before the arm.

You could also try some ferrite stuff (old VGA cables / computer PSU) around the motor wires or even shield the motor like the laminate stuff wrapped around tape decks motors.

I also see a lot of cable hanging before the arm.

You could also try some ferrite stuff (old VGA cables / computer PSU) around the motor wires or even shield the motor like the laminate stuff wrapped around tape decks motors.

Is it a BLDC motor? Does the PSU use PWM for the output.

A lot of the cheap controllers use PWM at 10kHz to power these motors and it can radiate noise into your system.

It is not limited to cheap controllers. The VPI HW40 uses a $570 controller and it also uses 10kHz PWM and can radiate up to 180mVPP of noise into 47kΩ.

Presumably BLDC means brushless DC motor, no it's got brushes.

I'll see if I can use an app to identify the frequency of the noise. It should stand out.

Some of those ferrite chokes sound like a cheap and easy thing to try, so I'll give that ago also.

And if I put a capacitor across the input to the speed controller, do I need to go high or low with capacitance. Will my 1uf be worth a try, or I have some much higher capacitance from an amp.

Cheers for all the suggestions, I think my initial capacitors acros the motor have actually made things worse. Listening last night the low pass filter on the amp could remove the noise, only lower it's volume.

Assuming that you don't want to try building a specific DC supply controller for your motor, you could try just getting the maximum separation you can between the signal cables and motor electronics.

I've had some experience with this on my Heybrook TT2 where I'd been tolerating a buzz, hum , rice krispie noise that was only present when the motor was running, and only audible close to the speakers. But it really began to get on my nerves.

With the arrangement of phono pre, preamp, and power amp I had to have the phono cables running within a few inches of the motor supply board and mains lead. It was a complete pain (I had to reposition the TT supports), but I rearranged everything so I could have the phono leads head in the opposite direction to the motor and completely away from any mains/motor cabling.

The result was complete silence.

I've had some experience with this on my Heybrook TT2 where I'd been tolerating a buzz, hum , rice krispie noise that was only present when the motor was running, and only audible close to the speakers. But it really began to get on my nerves.

With the arrangement of phono pre, preamp, and power amp I had to have the phono cables running within a few inches of the motor supply board and mains lead. It was a complete pain (I had to reposition the TT supports), but I rearranged everything so I could have the phono leads head in the opposite direction to the motor and completely away from any mains/motor cabling.

The result was complete silence.

Presumably BLDC means brushless DC motor, no it's got brushes.

I'll see if I can use an app to identify the frequency of the noise. It should stand out.

Some of those ferrite chokes sound like a cheap and easy thing to try, so I'll give that ago also.

And if I put a capacitor across the input to the speed controller, do I need to go high or low with capacitance. Will my 1uf be worth a try, or I have some much higher capacitance from an amp.

Cheers for all the suggestions, I think my initial capacitors acros the motor have actually made things worse. Listening last night the low pass filter on the amp could remove the noise, only lower it's volume.

A brushed DC motor may still have a controller with PWM output. If this is the case, and it is the source of your noise, I don't know if a cap across the output will be sufficient; it may require an LC filter. It may be easier/better to just replace the controller with a regulated DC output type rather than PWM with a switching frequency in the audio range.

Is there a cheap way of proving the PSU is the problem - i don't really want to buy a linear PSU only to find it wasn't that.

Ben

Its very likely to be the speed controller. You need one with ultrasonic PWM, and that's not universal by any means.

1uF is probably too large across the motor terminals, that's going to cause high current spikes. 10nF ceramic is much better compromise between filtering out RFI and not generaring big current spikes from the speed controller PWM.

Use twisted pair wherever high current supply of motor drive wiring is involved,

much less EMI is radiated from twisted pair than random wires snaking around.

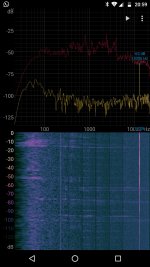

I've not got round to trying any fixes yet, but I have run a frequency analysis on my phone. There is a very high peak at 13khz. And I looked up the speed controller I bought it runs at 10khz nominally, given inaccuracies in the speed controller and my phone doing a fast Fourier transform, I suspect the speed controller is the candidate. I've ordered a new one which runs at 25khz, pretty sure that's out side my audible range by a few Hz!

Hopefully I'll be able to post the out put of the FFT, in case anyone is interested, my wife wasn't.

Hopefully I'll be able to post the out put of the FFT, in case anyone is interested, my wife wasn't.

Thank you very much for everyone's help on this.

I have installed a new 25khz PWM speed controller, and the high pitched noise has disappeared, or at least shifted beyond my hearing range.

Also I twisted the wire pairs together and installed a ferrite choke on the power cable for good measure. These two didn't fix the problem, but seem to be good practice any way.

cheers

Ben

I have installed a new 25khz PWM speed controller, and the high pitched noise has disappeared, or at least shifted beyond my hearing range.

Also I twisted the wire pairs together and installed a ferrite choke on the power cable for good measure. These two didn't fix the problem, but seem to be good practice any way.

cheers

Ben

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Turntable high pitch noise problem