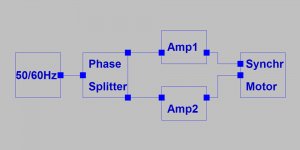

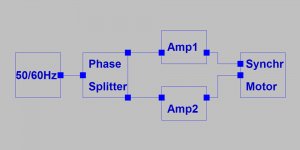

Driving a synchronous turntable motor needs two signals 90 degrees apart, generated with a stable 50Hz/110V or 60Hz/230V frequency depending on the country where you live.

The simplest way is to use the local mains frequency and a capacitor to do the phase shifting for the second phase.

The mains frequency however is most of the time not being a perfect sine shaped wave and may be further polluted by many high frequency peaks caused by domestic equipment, apart from the fact that the mains frequency is jittering around the nominal frequency caused by varying loads in your local area.

Stable phase shifting by means of a capacitor works only when 1) the input signal is a perfect sine shaped signal and 2) with a non-varying load. None of both is true when feeding the motor directly from the mains supply.

To have a better situation to start with, VPI offers the SDS, a device that is producing a stable sine shaped signal to directly drive the motor, thereby isolating all problems that comes with the mains supply.

However, phase shifting needed for the second motor drive voltage is still done by the same capacitor as before. Since the load that the motor presents to this capacitor is not stable, the second phase will be a jittering signal leading to torque changes and hence to rumble.

Linn with its well praised LP12 turntable, uses the Lingo power supply to provide the two motor phases electronically, thereby ensuring a perfect constant torque motor drive, preventing the need to use a super heavy platter to damp the motor vibrations.

That a capacitor is not the ideal component for making the second phase can be shown with a so called Lissajou figure, by offering one phase to the X input and the other phase to the Y input of a scope.

Two sine shaped signals, each 90 degrees apart, will result in this way in a perfect circle.

Zero degrees phase shift will result in a straight line, tilted 45degrees and all phases in between will result in an oval shaped, but only if the phase shift between the two phases is constant all the time.

If the phase shift is not constant, it will result in a distorted oval or circle.

So lets have a look at the Lissajou figure of the phases directly on the motor driving a VPI Scoutmaster.

So what you see is a distorted oval, telling two things. Because it is not a circle but an oval means that the phase shift is not 90 degrees, causing the motor to have less torque.

And because of the distortion of the oval it is obvious that the phase shift jitters, and so does the motor thereby causing rumble.

The solution is of course the way Linn did it by supplying the two phases instead of just one, and to get rid of the dreaded capacitor used for this function.

The 50/60 Hz generator can be made in many ways, to give a few examples:

- precision sine wave generator

- digitally, starting with a Xtal osc, dividing to 50 or 60Hz, then bandpass filtering to get a sinus shaped signal

- using a uProcessor and let the internal D/A convertor generate a sinus

In my case I used a Project Speed box that is using the third example and generated a signal of 50Hz and 67.5 Hz for 33 1/3 and 45 RPM, but it will be pretty easy to use some low cost uP and do the programming yourself.

Depending on the quality of the signal you may have to add some filtering.

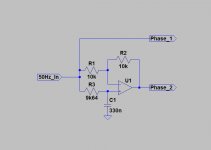

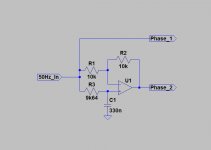

Then comes the phase splitter.

The frequency where the phase shift is 90 degrees is 1/(2 x Pi x R3 x C1).

In the example above this is 50Hz.

By changing the value of R3, you can alter the 90 degree phase shift point to your need.

You could even add a second resistor plus a switch parallel to R3 to be able to switch between 33 1/3 and 45 RPM.

Gain of this splitter is 1X, so both phases have the same amplitude. It is therefore wise to have a signal coming from the generator that can be varied in amplitude, this will affect both phases.

Next in line are the 2 amplifiers steering the turntable motor.

You could make your own design for a 110V or 230V amplifier, which can be done, but it is not the easiest way.

What I did was to use a cheap (second hand) stereo amplifier and feed it with the signals from the phase splitter to get an output signal of 15 Volt, by varying the amplitude of the generator output.

The output of the stereo amp is fed to two small 15V/230V toroid trafos that are directly feeding the turntable motor.

Again displayed as a Lissajou figure, this is how it looks.

Hans

The simplest way is to use the local mains frequency and a capacitor to do the phase shifting for the second phase.

The mains frequency however is most of the time not being a perfect sine shaped wave and may be further polluted by many high frequency peaks caused by domestic equipment, apart from the fact that the mains frequency is jittering around the nominal frequency caused by varying loads in your local area.

Stable phase shifting by means of a capacitor works only when 1) the input signal is a perfect sine shaped signal and 2) with a non-varying load. None of both is true when feeding the motor directly from the mains supply.

To have a better situation to start with, VPI offers the SDS, a device that is producing a stable sine shaped signal to directly drive the motor, thereby isolating all problems that comes with the mains supply.

However, phase shifting needed for the second motor drive voltage is still done by the same capacitor as before. Since the load that the motor presents to this capacitor is not stable, the second phase will be a jittering signal leading to torque changes and hence to rumble.

Linn with its well praised LP12 turntable, uses the Lingo power supply to provide the two motor phases electronically, thereby ensuring a perfect constant torque motor drive, preventing the need to use a super heavy platter to damp the motor vibrations.

That a capacitor is not the ideal component for making the second phase can be shown with a so called Lissajou figure, by offering one phase to the X input and the other phase to the Y input of a scope.

Two sine shaped signals, each 90 degrees apart, will result in this way in a perfect circle.

Zero degrees phase shift will result in a straight line, tilted 45degrees and all phases in between will result in an oval shaped, but only if the phase shift between the two phases is constant all the time.

If the phase shift is not constant, it will result in a distorted oval or circle.

So lets have a look at the Lissajou figure of the phases directly on the motor driving a VPI Scoutmaster.

So what you see is a distorted oval, telling two things. Because it is not a circle but an oval means that the phase shift is not 90 degrees, causing the motor to have less torque.

And because of the distortion of the oval it is obvious that the phase shift jitters, and so does the motor thereby causing rumble.

The solution is of course the way Linn did it by supplying the two phases instead of just one, and to get rid of the dreaded capacitor used for this function.

The 50/60 Hz generator can be made in many ways, to give a few examples:

- precision sine wave generator

- digitally, starting with a Xtal osc, dividing to 50 or 60Hz, then bandpass filtering to get a sinus shaped signal

- using a uProcessor and let the internal D/A convertor generate a sinus

In my case I used a Project Speed box that is using the third example and generated a signal of 50Hz and 67.5 Hz for 33 1/3 and 45 RPM, but it will be pretty easy to use some low cost uP and do the programming yourself.

Depending on the quality of the signal you may have to add some filtering.

Then comes the phase splitter.

The frequency where the phase shift is 90 degrees is 1/(2 x Pi x R3 x C1).

In the example above this is 50Hz.

By changing the value of R3, you can alter the 90 degree phase shift point to your need.

You could even add a second resistor plus a switch parallel to R3 to be able to switch between 33 1/3 and 45 RPM.

Gain of this splitter is 1X, so both phases have the same amplitude. It is therefore wise to have a signal coming from the generator that can be varied in amplitude, this will affect both phases.

Next in line are the 2 amplifiers steering the turntable motor.

You could make your own design for a 110V or 230V amplifier, which can be done, but it is not the easiest way.

What I did was to use a cheap (second hand) stereo amplifier and feed it with the signals from the phase splitter to get an output signal of 15 Volt, by varying the amplitude of the generator output.

The output of the stereo amp is fed to two small 15V/230V toroid trafos that are directly feeding the turntable motor.

Again displayed as a Lissajou figure, this is how it looks.

Hans

Hi Hans

Was looking at the Project speed boxes looks like they want low watt motors. Yours has a amp before the step up tramformers so how many watts can it put out?

The reason I ask is the one Hurst motor is a 14 watt motor. Also could I come off my phoenix eagle which is good for 15 watts and split there?

Thanks Tom

Was looking at the Project speed boxes looks like they want low watt motors. Yours has a amp before the step up tramformers so how many watts can it put out?

The reason I ask is the one Hurst motor is a 14 watt motor. Also could I come off my phoenix eagle which is good for 15 watts and split there?

Thanks Tom

Hello Hans,

what do you think about using a commercial amplifier with 100V outputs to directly drive the motor?

Any amplifier capable of generating a high enough voltage and supplying at least 100mA will do.

A motor normally running at 110v rms will probably work at 100v rms.

Give it a try, and if it works you won'tneed the trafo's.

Hans

You would need a very large amp to directly drive a 115VAC motor. 115V RMS is 325VPP so you would have to have ±163VDC rails minimum. This would equate to a 1.6kW amp into 8 Ohms. You could drive the motor at a lower voltage (75VAC), but it will most likely have trouble starting a heavy platter, especially at 45 RPM. 75V RMS is ~700W into 8 Ohms.

I've completely given up on Hurst motors for turntables, I think they are ill-suited for the task. All of the Hurst motors I have vibrate terribly, and some of them would not run from a dual phase supply without modification. The Premotec motors behave better in all aspects, but are very low power (torque). I've been using a BLDC motor with 3 phase drive and it is head and shoulders above the Hursts:

BLDC Turntable motor

I've completely given up on Hurst motors for turntables, I think they are ill-suited for the task. All of the Hurst motors I have vibrate terribly, and some of them would not run from a dual phase supply without modification. The Premotec motors behave better in all aspects, but are very low power (torque). I've been using a BLDC motor with 3 phase drive and it is head and shoulders above the Hursts:

BLDC Turntable motor

You would need a very large amp to directly drive a 115VAC motor. 115V RMS is 325VPP so you would have to have ±163VDC rails minimum. This would equate to a 1.6kW amp into 8 Ohms. You could drive the motor at a lower voltage (75VAC), but it will most likely have trouble starting a heavy platter, especially at 45 RPM. 75V RMS is ~700W into 8 Ohms.

BLDC Turntable motor

There are many PA amplifiers being able to supply these high voltages. However they are meant to be driving the speakers through local step down transformers, their power output is just average.

The advantage is that you can attach many small speakers and the line from the amplifier to speaker can be relatively thin.

Such amplifier could without a doubt drive a turntable motor.

Hans

Thanks Hans,

I have verified that the hurst motor that came with my VPI HW-19 will start up on 100 VAC and the standard phasing cap. It is an early platter with lead filling so pretty heavy compared to the latest stuff. When I run it at a lower voltage it seems to help with the vibration. I ended up building a separate motor pod though as the vibration never got to the level where I could not detect it in the plinth when the motor was attached to the base.

I have verified that the hurst motor that came with my VPI HW-19 will start up on 100 VAC and the standard phasing cap. It is an early platter with lead filling so pretty heavy compared to the latest stuff. When I run it at a lower voltage it seems to help with the vibration. I ended up building a separate motor pod though as the vibration never got to the level where I could not detect it in the plinth when the motor was attached to the base.

I hadn't considered PA amps which are available in 70VRMS and 100VRMS. The 70V version would most likely be too low to drive a motor, but 100V might work. Both are rated at peak output, not continuous levels that would be needed for a motor, although the motor power is considerably less than most of these amps are rated for. Most of these amps use internal step up transformers, so I'm not sure what you are gaining by doing this? There are directly coupled 100V PA amps, but they are considerably mroe expensive and usually high power (250W or more). To each his own I guess.

Hans-

I just re-read your first post and there are a couple of inaccuracies in it:

Torque ripple (cogging) is not caused by incorrect phase alignment of the drive signals, it is caused by the variable reluctance of the stator cores and their interaction with the PM rotor. Motor vibration can be reduced by careful adjustment of the 2 phases (90° is not necessarily the optimum value and it will vary with load), but there will always be a certain amount of cogging in AC synch motors with iron cores. Linn motors driven by the Lingo still exhibit torque ripple.

Your first Lissajou pattern is distorted because one (or both) of the input signals is not a clean sinewave, not because of phase jitter. If the phase of one of the signals is wobbling, the oval will also wobble back and forth or be blurred, but it does not cause the type of distortion your screen shot shows.

Using a dual phase supply is definitely a step in the right direction with AC synch motors. I would suggest using caution though when working with the Hurst motors as half of the ones I've tested will stall when driven this way (the other half ran smoother and had more torque than when driven from a single supply).

I just re-read your first post and there are a couple of inaccuracies in it:

Torque ripple (cogging) is not caused by incorrect phase alignment of the drive signals, it is caused by the variable reluctance of the stator cores and their interaction with the PM rotor. Motor vibration can be reduced by careful adjustment of the 2 phases (90° is not necessarily the optimum value and it will vary with load), but there will always be a certain amount of cogging in AC synch motors with iron cores. Linn motors driven by the Lingo still exhibit torque ripple.

Your first Lissajou pattern is distorted because one (or both) of the input signals is not a clean sinewave, not because of phase jitter. If the phase of one of the signals is wobbling, the oval will also wobble back and forth or be blurred, but it does not cause the type of distortion your screen shot shows.

Using a dual phase supply is definitely a step in the right direction with AC synch motors. I would suggest using caution though when working with the Hurst motors as half of the ones I've tested will stall when driven this way (the other half ran smoother and had more torque than when driven from a single supply).

OK we went from set up transformers to direct voltage out. It looks like you are going to need a pretty good size pa amp to do this.

So back to the step up transformer out. Audio amps talk in watts out to 4/8/16 load speakers. So if we work backwards let's say I need 15 watts for the current motor. Using a step up transformer how many watt amp is needed. Also was thinking about car amps that are pretty high powered in a small package.

Thanks Tom

So back to the step up transformer out. Audio amps talk in watts out to 4/8/16 load speakers. So if we work backwards let's say I need 15 watts for the current motor. Using a step up transformer how many watt amp is needed. Also was thinking about car amps that are pretty high powered in a small package.

Thanks Tom

Of the AC synchronous motor types, the one that is most suited to this application is the Hysteresis Synchronous type, which use a high magnetic hysteresis material in the rotor for torque production. With good clean drive signals, these motors will accelerate most any load (like a massive platter) smoothly and lock into synchronous operation with essentially zero torque ripple. I'm not aware of anyone who is manufacturing them these days, buy they are sometimes available as surplus. Hurst, among others, used to manufacture them.

If you are going for low ripple torque with a PMBDC motor, it takes more than a clean sinusoidal current drive to get there. You also need a motor with a sinusoidal torque-angle characteristic. When driven with a sinusoidal current in each phase, a 3-phase PMBDC motor with a sinusoidal torque-angle will produce a ripple free output torque. Distortion on either the current or torque-angle waveform will generate ripple torque.

If you are going for low ripple torque with a PMBDC motor, it takes more than a clean sinusoidal current drive to get there. You also need a motor with a sinusoidal torque-angle characteristic. When driven with a sinusoidal current in each phase, a 3-phase PMBDC motor with a sinusoidal torque-angle will produce a ripple free output torque. Distortion on either the current or torque-angle waveform will generate ripple torque.

In my experience, it's not as simple as you would like it to be. In theory, a 15W motor should require a little more than 15W output at the amp (allowing for 5-15% loss in the xfmr). However at start up, there will be a significant current draw due to core magnetization in the xfmr, so it might require a much larger amp to prevent oscillations or overload resulting in the amp shutting down.

At start up, the xfmr will present a very low impedance to the output of the amp. Assuming it can handle this, it will stabilize and the impedance seen by the output of the amp will be (approximately), the DC resistance of the motor coils divided by the square of the xfmr turns ratio. Calculating the turns ratio is not as straight forward as it seems: a 12V-120V xfmr does not have a 10:1 turns ratio. Most of the xfmrs will be designed for 115VAC input, but the rated output voltage is at full load. A close approximation of turns ratio would be input voltage/no load output voltage, which for a 12VAC xfmr will be ~15V so the turns ratio is closer to 7.66:1.

Your 15W motor should have windings of ~880 Ohms; using a 12V xfmr, the load presented to the amp would be ~15 Ohms and you would need to provide 15VRMS (42VPP) to get 115VAC at the output of the xfmr.

This is an oversimplification of the process and ignores losses in the xfmr, back EMF generated by the motor and parasitic components throughout, but it should be a reasonably close approximation.

At start up, the xfmr will present a very low impedance to the output of the amp. Assuming it can handle this, it will stabilize and the impedance seen by the output of the amp will be (approximately), the DC resistance of the motor coils divided by the square of the xfmr turns ratio. Calculating the turns ratio is not as straight forward as it seems: a 12V-120V xfmr does not have a 10:1 turns ratio. Most of the xfmrs will be designed for 115VAC input, but the rated output voltage is at full load. A close approximation of turns ratio would be input voltage/no load output voltage, which for a 12VAC xfmr will be ~15V so the turns ratio is closer to 7.66:1.

Your 15W motor should have windings of ~880 Ohms; using a 12V xfmr, the load presented to the amp would be ~15 Ohms and you would need to provide 15VRMS (42VPP) to get 115VAC at the output of the xfmr.

This is an oversimplification of the process and ignores losses in the xfmr, back EMF generated by the motor and parasitic components throughout, but it should be a reasonably close approximation.

Last edited:

So it is more complex than I imagined. That happens to me all of the time  getting back to optimal drive... If a perfect wave is not optimal could feed back generate the required wave to smooth the motor? I.E if you drove one identical motor with another and used the coils of the non driven motor to feedback a voltage to the amplifying stage would you end up with the right wave shape?

getting back to optimal drive... If a perfect wave is not optimal could feed back generate the required wave to smooth the motor? I.E if you drove one identical motor with another and used the coils of the non driven motor to feedback a voltage to the amplifying stage would you end up with the right wave shape?

Marcus your post caught my eye on the hysteresis type motor so I looked it up. Seems they where use a lot on reel to reel tape decks. Did these tape decks use any special power supplies or just ac from the wall. If you where a betting man would you think you would get a better running motor with a hysteresis motor with ac from the wall or a standard synchronous motor with a controller with or without phrase control?

Thanks Tom

Thanks Tom

Hans-

I just re-read your first post and there are a couple of inaccuracies in it:

Torque ripple (cogging) is not caused by incorrect phase alignment of the drive signals, it is caused by the variable reluctance of the stator cores and their interaction with the PM rotor. Motor vibration can be reduced by careful adjustment of the 2 phases (90° is not necessarily the optimum value and it will vary with load), but there will always be a certain amount of cogging in AC synch motors with iron cores. Linn motors driven by the Lingo still exhibit torque ripple.

Your first Lissajou pattern is distorted because one (or both) of the input signals is not a clean sinewave, not because of phase jitter. If the phase of one of the signals is wobbling, the oval will also wobble back and forth or be blurred, but it does not cause the type of distortion your screen shot shows.

Using a dual phase supply is definitely a step in the right direction with AC synch motors. I would suggest using caution though when working with the Hurst motors as half of the ones I've tested will stall when driven this way (the other half ran smoother and had more torque than when driven from a single supply).

I can just tell what my experience was so far.

Removing the belt and putting the stylus on an LP with the engine running, resulted in a much lower rumble noise with the two phase steering.

That's why I have made the same setup for a number of friends with VPI turntables with exactly the same result.

Never was there a motor that stalled during start up, but that may be because of the large power margin the amps could supply.

So whatever it may be called or what the exact cause is, rumble was significant lower, that's all that counted for me.

Because of the possibility to adjust the drive voltage, I tuned the voltage giving the lowest rumble, which was lower than the 230V that the motor was designed for.

And although the belt is screaming a bit, I never had a problem at start up and speed is reached in halve a turn with the heavy scoutmaster platter including an also heavy peripheral ring.

Hans

So what kind of current are we looking at to be on the safe side? I also push both my 32 lb and 38 pound platters to start them.

Thanks Tom

When using an amplifier capable of at least 30W@8Ohm per channel, you will have more than enough power to drive the motor.

I have never measured the current at start up, but I will try to do this tomorrow and publish the results.

As Scott Wurcer recently mentioned: it doesn't matter who is right, it only matters to get it right.

Hans

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Optimally driving a (VPI) synchronous turntable motor