A few weeks ago, I bought a Weathers "the Townsend" turntable off the bay for a fair price. After opening the original box i was little put off by the extremely light weight of the platter (less than 1 pound!) and the miniscule size of the idler and motor. (Pics below). Well after fiddling a bit to get the speed right and the tonearm to track correctly, I found it sounded as good as any of the idler wheel tt's I have. (dual 1019, qrk 12 c, dual 1219, rek o kut l34 etc) It had the idler wheel magic of clearing up the smeared low level music and just more of a sense of realism then my belt drives. It got me thinking that if the idler wheel turntable's forte is speed stability, how come this puny idler wheel matched up to a light weight platter could sound so good. This turntable could not possibly hold its speed as good as the qrk or dual turntables with their heavy platters. A dust brush could slow the Weathers down! It had to be something else, I thought. So with that in mind, I cobbled up the below idler wheel mounted on a dust brush pedestal. Rested it to the platter of my Ariston rd 40 belt drive and bingo! Same sound as from an idler drive! No smearing of the low level music, and the same sense of the musicians being in the room with me! My guess is that the idler dampens the platter in a good way and clears up the low level sounds. Tried it on my Empire and same results. It's easy to a-b test since I can place the idler on and off the platter in a second or two. Has anyone else tried this and had similar results? Or am I imagining this? I think I have a pretty good ear and it sure sounds better to me. I would love for someone else to try this to see if it's as noticeable as I think. Or better yet. Could someone tell me how to go about testing this through the speakers. I know my turntables are not high end by any means so maybe this would not have as profound an effect on say a Sota Sapphire!

BTW, I posted this on another site, but received all kinds of unrelated

And..

I see at least one person on here agrees that the driveline vibrations are all to do with the sonic differences between belt, direct, and idler drive turntables.

My theory as stated above is that the freewheeling idler on the outside of the belt drive platter dampens the rotating platter's bad vibrations and lets the high fidelity lor lack of) of the recording shine through unimpeded. Any thoughts on how to test. Im not afaid to be "proved" wrong either. I'm on a mission to find outt one way or another. Please help!

Thank you all in advance!

BTW, I posted this on another site, but received all kinds of unrelated

And..

I see at least one person on here agrees that the driveline vibrations are all to do with the sonic differences between belt, direct, and idler drive turntables.

My theory as stated above is that the freewheeling idler on the outside of the belt drive platter dampens the rotating platter's bad vibrations and lets the high fidelity lor lack of) of the recording shine through unimpeded. Any thoughts on how to test. Im not afaid to be "proved" wrong either. I'm on a mission to find outt one way or another. Please help!

Thank you all in advance!

Great experiment! I did something similar with two identical platters from direct-drive turntables, one passive and one active. The passive platter is being driven by the active platter acting as the motor. The interface is either VHS tape as "belt-drive" or a salvaged Lenco idler wheel as "idler-drive" and finally "direct-drive" of itself. Each has its sonic character of its genre. The VHS set-up sounded like belt-drive and idler wheel set up sounded like idler-drive, etc... I think you made a great point about the idler wheel damping the platter plays a role in the sound but I also believe the compliant characteristic of the interface--be it a belt, tape, thread, or idler wheel--gives the set-up its sonic signature. Even a thicker puck has a "thicker" sound over a thin one. It's almost like a tone control. Idler wheel invariably gives a more meaty robust juicy sound and I miss that when I switch to VHS tape but lower noise and less fiddling is attractive to me. It's like food: there's no "best" food. Try everything!

Here's a thread that shows pictures of the VHS tape set-up. Not discussed in the thread but I also did an idler experiment with a Technics SL-1700Mk2 table acting as motor, idler wheel from Lenco, driving the same platter. The Technics has speed adjustment so it's convenient but the beveled platter doesn't help so I added another platter on top acting as pulley. I would have used a Technics SL-M2 or M3 if I had one at the time.

Below are pictures that give you some ideas.

Here's a thread that shows pictures of the VHS tape set-up. Not discussed in the thread but I also did an idler experiment with a Technics SL-1700Mk2 table acting as motor, idler wheel from Lenco, driving the same platter. The Technics has speed adjustment so it's convenient but the beveled platter doesn't help so I added another platter on top acting as pulley. I would have used a Technics SL-M2 or M3 if I had one at the time.

Below are pictures that give you some ideas.

Now I know I'm on the right website!! Nice work. Love peoples experiments!

I agree with the tonal change the idler makes too. Kind of like a miniature spinning subwoofer. I also find that high frequency sounds are increased too with the freewheeling idler.

In my sleep deprived stupor, I forgot to post my pictures. Will do that later on.

Any ideas on how I can measure the frequency change would be appreciated!

Regards,

Dominic

I agree with the tonal change the idler makes too. Kind of like a miniature spinning subwoofer. I also find that high frequency sounds are increased too with the freewheeling idler.

In my sleep deprived stupor, I forgot to post my pictures. Will do that later on.

Any ideas on how I can measure the frequency change would be appreciated!

Regards,

Dominic

Dominic: thanks for taking the time to post about your efforts and findings. So your guess is that the idler is damping the platter better than the belt does? I should think that you can tap a platter with the idler engaged (static) and tap it with something metal then listen to the ring. You can ten disengage the idler drive and pace a TT belt around the platter and repeat the process. You should be able to hear the difference between the two set ups. I would guess off the top of my head that the belt will do a better job of damping the platter as it is making contact over a much larger area. I suspect that platter resonance is not the only variable at play here.

What about if you were to run a belt with an equivalent pull force on the platter as the idle has push force? That way you can know that the main bearing is being offset as much with both drives. There must be a host of physical differences between the two drive methods. This is very interesting though. If this were simply a matter of damping one could damp a platter which was belt driven and it ought to sound the same as a non damped platter with an idler drive. Or if you were to install an idler wheel with no drive and then use the belt to power the platter what then? Please keep us posted as to what you try next and what you find. Best regards Moray James.

What about if you were to run a belt with an equivalent pull force on the platter as the idle has push force? That way you can know that the main bearing is being offset as much with both drives. There must be a host of physical differences between the two drive methods. This is very interesting though. If this were simply a matter of damping one could damp a platter which was belt driven and it ought to sound the same as a non damped platter with an idler drive. Or if you were to install an idler wheel with no drive and then use the belt to power the platter what then? Please keep us posted as to what you try next and what you find. Best regards Moray James.

Very interesting and cool observations. I had a variety of belt drives over the years, but my first idler (in modern history) a TD-124/II ended that run. I now have two TD-124, and it is precisely the drive and dynamics, and the good low level detail I find attractive about this table. I've had to work to get it quiet, and while definitely not as quiet as an SME 20, it is quieter than any of the records I play.. (Great main bearing and heavy cast iron platter, the motor is noisy but fairly well isolated at this point)

Another set up with my Technics SL-M3 few years ago. I don't have the M3 anymore but I still have an SL-M2 that's smaller footprint but using the same motor and platter. This time I used dental floss. And it sounded nice and no teeth pulling sound.

Another DD table that works really well is a JVC QL-F6 that has pitch control. Of course the disadvantage of such set up is that it takes so much table space!

What is the sound of one wheel spinning? This one uses idler and it's not a "bad" one either.

Another DD table that works really well is a JVC QL-F6 that has pitch control. Of course the disadvantage of such set up is that it takes so much table space!

What is the sound of one wheel spinning? This one uses idler and it's not a "bad" one either.

Last edited:

@ Moray...directdrive makes an interesting point to about the wheel coloring the sound. I thought that was part of it. Don't mind me forgetting some things in my first post. I'm a little shell shocked from all the unrelated and naysaying posts on my thread on that other forum. What a waste of bandwidth that one was. I baled out officially this am.

Can't even download my own pics from there!!

Pics this evening.

@ Kevinkr. The belt/idle sound ( we all know idlers have a distinct sound that i like the best..no offense..lol) of the td124 is one of the other reasons i did my experiment. While not a thorens, I have similar combo on a Kenwood..4021 it something. It too has more of a feeling of being in the room with musicians.

I think I can measure a change or no change in frequencies with and without freewheeling idler. Maybe I will search the speaker forum for tips on how too. I do appreciate the tip about checking tone of platter. And the dual belt thing to counter act the pulling on the bearing is interesting too. On the rd40, the idler was positioned to push the bearing where the belt pulls it. On the Empire, could not do this. Not sure it even compensated for the belt pull anyway.

Also, I was able to induce rumble with added bass and very high volume with the freewheeling idler. None whatsoever without it. That's why I thought it added a tone also. May be the only reason for the idlers charestic sound. Maybe not. I hope to find out!!

Dominic

Can't even download my own pics from there!!

Pics this evening.

@ Kevinkr. The belt/idle sound ( we all know idlers have a distinct sound that i like the best..no offense..lol) of the td124 is one of the other reasons i did my experiment. While not a thorens, I have similar combo on a Kenwood..4021 it something. It too has more of a feeling of being in the room with musicians.

I think I can measure a change or no change in frequencies with and without freewheeling idler. Maybe I will search the speaker forum for tips on how too. I do appreciate the tip about checking tone of platter. And the dual belt thing to counter act the pulling on the bearing is interesting too. On the rd40, the idler was positioned to push the bearing where the belt pulls it. On the Empire, could not do this. Not sure it even compensated for the belt pull anyway.

Also, I was able to induce rumble with added bass and very high volume with the freewheeling idler. None whatsoever without it. That's why I thought it added a tone also. May be the only reason for the idlers charestic sound. Maybe not. I hope to find out!!

Dominic

Over the years, my own suspicion on the sonic character of a turntable is determined mainly by three things. Let's focus on the three major genres, direct-drive (DD), belt-drive (BD), and idler-drive (ID). Let's assume all three turntables having the same bearing, same plinth, same platter--similar to my experiments above--to eliminate variables. The stylus, the one thing that actually creates a signal, does NOT care or know what drive system is being used, right? But it does "feel" few things in the process of creating a signal. And I believe these factors that the stylus can interact creates the sonic or tonal characters we associate with the three different genres: Torque, Cogging, Compliant characteristic of the Interface.

Below is an email, with minor edit, I sent to a friend a year ago discussing drive systems and their sonic attributes. They are not scientific studies, just mere observations from listening and tinkering so please don't take it so seriously, just in case the scope-jockeys want to jump on me! Once again, I don't favor one genre over the other and I like all flavors... just like my food.

Thank god for copy-and-paste! That's a lot of typing that I didn't have to redo.

.

Below is an email, with minor edit, I sent to a friend a year ago discussing drive systems and their sonic attributes. They are not scientific studies, just mere observations from listening and tinkering so please don't take it so seriously, just in case the scope-jockeys want to jump on me! Once again, I don't favor one genre over the other and I like all flavors... just like my food.

Torque. Sonically, the higher the torque the better dynamic and bass. This, I believe, has to do with the lessening stylus drag. The stylus simply plow through the groove without slowing down by the friction. Yes, the higher the torque the better in the dynamics department but the penalty is the higher the torque the higher the cogging. Even worse in slow speed.

Cogging. The fancy words in engineering term is torque linearity, any ripple or irregularity in the rotation the cartridge will tell you. It's a temporal thing and noise issue, like hum in amps.

Compliance of interface. Unless we have a perfect motor with zero cogging and zero vibration, we have to rely on some ways to combat those things and this is the key to the "sound" or tone of a turntable. All interface has compliance even a direct drive because it uses magnet and magnetic force is compliant otherwise we would be using gear drive! So we have three types of interface, whether it's a magnet, a belt, a wheel, they are all compliant, degrees of springiness, mostly made of rubber.

My conclusion is that regardless of which drive system IF one turntable has the same characteristic in Torque, Cogging, and Compliance, as another turntable that uses a different drive method, the sound will be the SAME. That is, a belt drive turntable having the same torque, same degree of cogging, and same interface compliance, as a direct drive or idler drive table, the sound will be the same or close to be the same. Of course, I haven't taken into the effect of bearing quality, material, coupling, etc... into account. But the "sound" of a turntable will be determined primarily by those three factors.

Let's examine each drive system:

Belt drive. Typically it uses the softest interface, a rubber belt that stretches which made worse by having a small pulley that can have slippage. It is not surprising it has the softest mellowest sound and quite easy on the ear because it filters and round off the cogging but at the same time round off the transience and attacks, much like the soft clipping nature of tube. Notice manufacturers beginning to use low compliant material like silk thread or magnetic tape like VHS or 1/4" tape. But materials like that are unforgiving on the quality of the motor and vibration. It puts a great demand on the motor. Another approach is to use huge mass and weak motor to "nudge" the platter to keep it up to speed. It works but very expensive and how it combats stylus drag is still questionable. I personally prefer bigger pulley with slower motor running at 300rpm so it's only 5Hz resonance, two octaves below audibility. And the pulley to platter ratio is 1 to 9. The beauty of belt drive is its mechanical simplicity and cheap cost and easy to get good sound. I think belt drive also preserve the "air" and spaciousness and ambiance better than other in the high frequency, all the microscopic groove modulations are preserved better due to the nature of its drive system. Alas, the lower frequencies are not the same story.

Idler drive. It has the thickest tone and not surprisingly it uses the thickest interface, a rubber wheel. A rubber wheel is a very effective way to transfer torque to the platter, hence the dynamic sound. It's also, by nature, the noisiest due to the closest contact with a typically fast motor. Not all idler table sound the same, depending on the thickness and softness of the tire. Personally, I like the sound when the tire is thick and soft, which is a combination that produces juiciest tone. Lenco doesn't have that tone but makes up for high torque and stable speed due to its clever vertical wheel system and its low contact area of the thin tire creates low noise. There's a lot of voodoo science and myth in idler system. I think a lot of people are simply surprised by how good it can sound and underestimated the effect of stylus drag so when they all of a sudden experience something so dynamic and tonally robust it startles them. There's no myth, it sounds good for a reason. It is best in the midrange and mid bass but lose out that tiny airiness on top and the tightness at the bottom.

Direct drive. I think "magnetic drive" is a better term but since the platter shares the same bearing with the motor we have to settle for the direct drive term. The amount of magnetic force and torque linearity/cogging are paramount in the sound of DD. I think modern DD designers are beginning to employ some of the techniques of belt drive in better bearing and platter quality. The more I read in internet forums, the more I feel people are misunderstanding DD. The concept of direct drive is really simple. But one thing the naysayer keep repeating is that the motor is directly underneath the platter so therefore it's noisy. It is, in fact, the QUIETEST system. There is only ONE single moving part and the speed is at 33rpm, which is HALF hertz! All platters in belt drive and idler turntables spins at half hertz PLUS noise from the high speed motor! In DD, the trick is to start with a good motor without complicated electronics. Sure, the complicated electronics can help smoothing things out but the motor itself needs to be high quality and smooth rotation/low cogging to begin with. Many Japanese DD tables rely on enormous electronic tricks to get a smooth rotation and STILL requires the inertia of the platter mass to smooth things out, hence my preference for coreless motors (of course its downside is weak torque) as right below the platter is a magnet on top of a series of iron-less coils. How simple can you get? The trick is to get these coils to nudge the magnet to spin smoothly. By overlapping the coils symmetrically, like the Dual motor, the force is very even and canceling out the cogging and add in the platter mass and inertia, you get very smooth rotation, smooth sound. The DD genre was on the right track with coreless motor but unfortunately its development got stopped by CD. I think the Brinkmann Bardo is on the right track by employing a lot of techniques from belt drive, such as bearing quality and platter mass and construction. And most importantly, the servo system is not as brutal as previous generation, much gentler and softer approach. I think the deconstructive approach will help the development of DD, that is, demystifying the genre. Looking at separate components and attack the issues one by one without losing sight of the big picture. Typically bass dynamic and tightness is, not surprisingly, its strong suit.

Again, regardless of which drive system a turntable uses, the torque, cogging, and interface compliance determines the majority of the sound and can possibly simulate one another, at least some if not all. Anything beyond that is called a hobby.

Thank god for copy-and-paste! That's a lot of typing that I didn't have to redo.

.

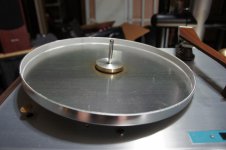

Pics as promised! First is the rim drive weathers motor and rubber wheel. The coin is for size reference. This is the reason I pursued this as posted earlier. Second is of the platter.Under a pound!! How can torque have anything to do with the idler sound if I can literally slow the platter on the weathers with a dust brush?! However when running, it sounds like an idler drive as stated! Third is of freewheeling idler on the ariston rd40, and fourth on the empire.

Directdrive, good work on your experiments. Careful on the finish on that Jvc. As you can tell Im a sucker for the rosewood base also!

I am going to read your email excerpt either later or tomorrow and comment on the "torque factor".

Later folks. And many thanks to all for commenting in a positive manner!

EXCELLENT!

Dominic

Directdrive, good work on your experiments. Careful on the finish on that Jvc. As you can tell Im a sucker for the rosewood base also!

I am going to read your email excerpt either later or tomorrow and comment on the "torque factor".

Later folks. And many thanks to all for commenting in a positive manner!

EXCELLENT!

Dominic

Attachments

Dominic: thanks for taking the time to post about your efforts and findings. So your guess is that the idler is damping the platter better than the belt does? I should think that you can tap a platter with the idler engaged (static) and tap it with something metal then listen to the ring. You can ten disengage the idler drive and pace a TT belt around the platter and repeat the process. You should be able to hear the difference between the two set ups. I would guess off the top of my head that the belt will do a better job of damping the platter as it is making contact over a much larger area. I suspect that platter resonance is not the only variable at play here.

What about if you were to run a belt with an equivalent pull force on the platter as the idle has push force? That way you can know that the main bearing is being offset as much with both drives. There must be a host of physical differences between the two drive methods. This is very interesting though. If this were simply a matter of damping one could damp a platter which was belt driven and it ought to sound the same as a non damped platter with an idler drive. Or if you were to install an idler wheel with no drive and then use the belt to power the platter what then? Please keep us posted as to what you try next and what you find. Best regards Moray James.

Moray, there was an article on the internet by a well regarded turntable manufacturer discussing his thoughts about eliminating friction in the bearing from the belts pulling action. He mentioned two opposing belts and a few other ideas he had. Will look up and read later on.

I plan on cobbling up a microphone set up going into to a preamp, than into a computer program to measure frequency change. Just to either prove or diprove any sound difference coming from my speakers caused by the addition of a freewheeling idler to the outside of the turntable platter. I just hope its not me "expecting" to hear this. Judging from direct drives first reply, I am not the only one to hear this difference! The folks designing speaker systems on this site should be able to help. Will search and probably make a thread when I finish working today.

That's all for now. Peace!

Dominic

Another belt-drive example from a blog, using a Technics SP-15 as motor driving a high mass platter:

DD, thanks for this! Those platters! Whoa! Epitome of inertia! Also, I am fascinated with the tonearm on his blog. Thanks again. I still have to check out the rest of your finds. Between work and crashing early from lack of sleep, I don't have much time. Will catch up over weekend.

Have a good one!

Dominic

Dominic: I don't think that a little friction is a bad think in fact it probably helps as long as your motor is up to the task some friction is fine. My best guess is what I mentioned before the idler applies more direct force on the platter than a belt drive does. So with more applied force the idler could well be applying a bias force on the spindle in the bearing assembly, in other words the idler is tilting the platter/spindle assembly inside the bearing assembly and that is making the platter more stable as it rotates. With a belt for drive the platter has more ability to wander and move about. The main bearing on the bottom of the spindle hunts for the point where it wants to spin on the thrust pad and so the platter can wobble back an forth within the slack of the keeper bearings. All that motion would explain the degraded sound. A simple test would be to tilt a belt drive table just enough to affect the same or similar offset or bias to the bearing assembly. Try that on a belt drive and tell me if it then sounds like an idled drive. Have a great weekend. Best regards Moray James.

PS: take a look at the three point contact bearing in a Well Tempered turn table, two points at the top of the spindle on one side and one contact point at the bottom of the spindle 180 degrees opposed. The platter is made to stand up and not allowed to wobble. With keeper bearings you will always have the slack in the bearing to permit wobble.

PS: take a look at the three point contact bearing in a Well Tempered turn table, two points at the top of the spindle on one side and one contact point at the bottom of the spindle 180 degrees opposed. The platter is made to stand up and not allowed to wobble. With keeper bearings you will always have the slack in the bearing to permit wobble.

Last edited:

Magic? Say it isn't so...

(or my take on on idler v. DD v. belt drive)

First I believe there to be good to excellent examples of each type.

Regarding the various drive schemes and hybrids:

Belt drive: easy to make, relatively easy to control, dampened belt. Best with "low-ish" power motors (operating at 250-300 Hz), higher mass platters (10 lbs.+). Accuracte machining, and implementation (including taking the belt mechanics into consideration) are required as well as precision machining.

DD: Hard to make, but when done correctly a potentially superior choice, particularly if the electronics are excellent. Often with "low mass" platters (2-5 lbs.) and slow powerful motors. The platter only acts as a surface to set records onto.

Rim drive or idler drive: Simple AC drive is easy, as long as accurately designed and machined (or in the case of the Dual and Lenco types with easy to use mechanical speed adjustments--I'm sure there are others so don't beat me up for not researching every idler speed adjustment types on idlers). Usually powerful motors spinning at high RPM and "medium" mass platters (say 5-10 lbs.).

Of course the hybrids: Belt drive to idler, idler to platter (as per Thorens, and VPI, etc). Often medium to heavy platters and powerful motors.

To me the crux of it all is the ability to conserve enough inertia to maintain a constant speed and reduce any motor effects (or minimize them), and the audible characteristics of the top plate, plinth, and platter.

My experiments with turntables thus far (and I am not suggesting I am an expert or have a lot of experience with anything but belt drives), is that to me the idler drive provides a good balance between a DD and a belt drive.One thing I was never expecting is the increase in soundstaging using an idler.

Regarding the need to offset a belt "pull" or idler "push" via additional belts or drives, the only thing I might suggest is the use of multiple motors. If enough inertia is conserved within the platter/motor/bearing system, then it becomes a moot point to offset the lateral force, just as it is moot to do the same for the cartridge mass riding within the groove.

(or my take on on idler v. DD v. belt drive)

First I believe there to be good to excellent examples of each type.

Regarding the various drive schemes and hybrids:

Belt drive: easy to make, relatively easy to control, dampened belt. Best with "low-ish" power motors (operating at 250-300 Hz), higher mass platters (10 lbs.+). Accuracte machining, and implementation (including taking the belt mechanics into consideration) are required as well as precision machining.

DD: Hard to make, but when done correctly a potentially superior choice, particularly if the electronics are excellent. Often with "low mass" platters (2-5 lbs.) and slow powerful motors. The platter only acts as a surface to set records onto.

Rim drive or idler drive: Simple AC drive is easy, as long as accurately designed and machined (or in the case of the Dual and Lenco types with easy to use mechanical speed adjustments--I'm sure there are others so don't beat me up for not researching every idler speed adjustment types on idlers). Usually powerful motors spinning at high RPM and "medium" mass platters (say 5-10 lbs.).

Of course the hybrids: Belt drive to idler, idler to platter (as per Thorens, and VPI, etc). Often medium to heavy platters and powerful motors.

To me the crux of it all is the ability to conserve enough inertia to maintain a constant speed and reduce any motor effects (or minimize them), and the audible characteristics of the top plate, plinth, and platter.

My experiments with turntables thus far (and I am not suggesting I am an expert or have a lot of experience with anything but belt drives), is that to me the idler drive provides a good balance between a DD and a belt drive.One thing I was never expecting is the increase in soundstaging using an idler.

Regarding the need to offset a belt "pull" or idler "push" via additional belts or drives, the only thing I might suggest is the use of multiple motors. If enough inertia is conserved within the platter/motor/bearing system, then it becomes a moot point to offset the lateral force, just as it is moot to do the same for the cartridge mass riding within the groove.

Nanook, a few self proclaimed audiophile experts on another forum gave me hell for saying the idler drive turntables soundstage is just better. However i am on a mission to either prove or disprove there is a difference for the better and i don't think it's from what every else says. Peace. Out for now!

Dominic

Dominic

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Idler wheel "magic"...