I have to quote myself to restore the images, so here is reply #6 in this thread:

The slate improved the sound compared to the original Dual 701. Dual 701 is not a bad design, but it's arm could be better, somewhat overengineered to my liking.

I was not very satisfied with the stroboscope light, because I wanted the stroboscope to be visible during record playing. The stroboscope is printed at the underside of the acrylic platter, and with the light emitting diodes under the printing, the stroboscope was only visible without a record on the platter.

I did use this circuit for the stroboscope light:

I replaced the leds with a brighter one taken from a broken computer mouse and put a couple of zeners in the circuit:

The result was a much brighter and sharper blinking, so that the stroboscope got clearer and sharper. I placed the led behind the platter, angled slightly upwards, and now I can see the stroboscope clearly through the edge of the platter.

The slate improved the sound compared to the original Dual 701. Dual 701 is not a bad design, but it's arm could be better, somewhat overengineered to my liking.

I was not very satisfied with the stroboscope light, because I wanted the stroboscope to be visible during record playing. The stroboscope is printed at the underside of the acrylic platter, and with the light emitting diodes under the printing, the stroboscope was only visible without a record on the platter.

I did use this circuit for the stroboscope light:

I replaced the leds with a brighter one taken from a broken computer mouse and put a couple of zeners in the circuit:

The result was a much brighter and sharper blinking, so that the stroboscope got clearer and sharper. I placed the led behind the platter, angled slightly upwards, and now I can see the stroboscope clearly through the edge of the platter.

Last edited:

And here is my reply #13 in this thread:

The mass of the platter is 2.4 kg, together with the rotor of the motor the total should be around 4 kg.

The platter from above, with flash:

The markings on the underside of the platter should be clear enough

The motor and the spindle on top. Also a picture of the motor from above:

The led behind the platter:

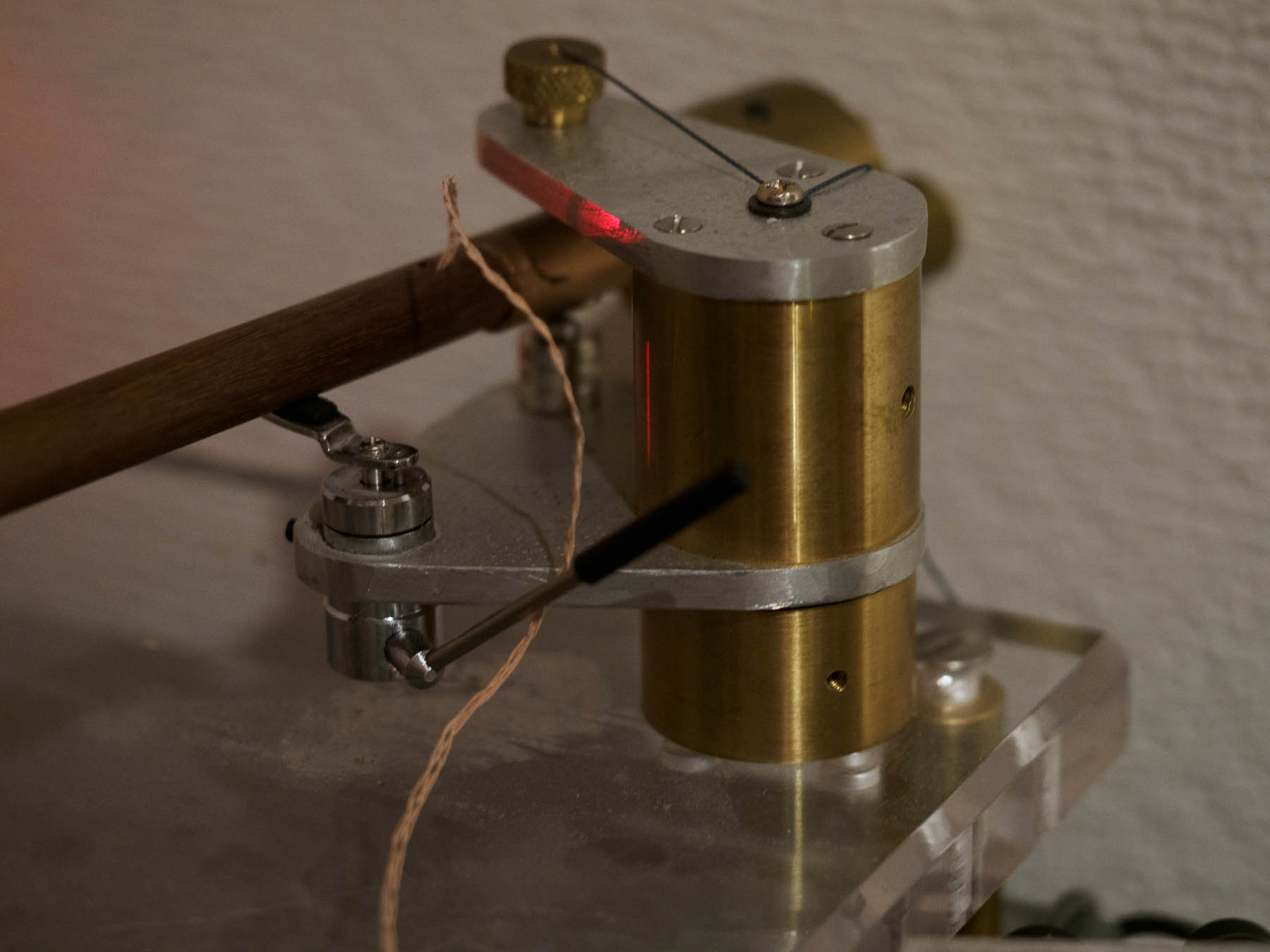

And here are some of the parts for the arm, brass and cocombole:

The mass of the platter is 2.4 kg, together with the rotor of the motor the total should be around 4 kg.

The platter from above, with flash:

The markings on the underside of the platter should be clear enough

The motor and the spindle on top. Also a picture of the motor from above:

The led behind the platter:

And here are some of the parts for the arm, brass and cocombole:

Have you thought of decoupling the spindle from the bearing shaft by adding a gap? This way, the noise from the bearing will not transmit all the way up to the spindle which is touching the record. So many bearing shafts are machined with the spindle as one piece and I think separate them should help reducing noise. I think cutting a gap shouldn't be too hard. The top half can be glue to the acrylic platter and the bottom half stays on the motor and is used for centering the platter, and the two parts don't touch each other.

Since I have the Dual motor and the acrylic platter myself, it's something I contemplated of doing, except I am not a machinist.

Anyway, just a thought!

Long time, no see  This project has been frozen too long, but two days ago I could finally spin records with the cocombole/pernambuco (I am not sure what is correct) arm, and it sounds really good. There have been a lot of procrastination in this project, so almost 15 years have passed. In the meantime I have moved three times, and a few years ago, I retired from work.

This project has been frozen too long, but two days ago I could finally spin records with the cocombole/pernambuco (I am not sure what is correct) arm, and it sounds really good. There have been a lot of procrastination in this project, so almost 15 years have passed. In the meantime I have moved three times, and a few years ago, I retired from work.

But the slate turntable have been sitting on top of my rack, with the unfinished arm laying around for years. While I was still in work, I machined the arm in a lathe. Without the lathe, I could never managed to make a hole trough the arm. Then: to solder the ultrathin wires seemed scary to me, but at last I had to.

So here it is, playing records and making me enjoy it a lot

But the slate turntable have been sitting on top of my rack, with the unfinished arm laying around for years. While I was still in work, I machined the arm in a lathe. Without the lathe, I could never managed to make a hole trough the arm. Then: to solder the ultrathin wires seemed scary to me, but at last I had to.

So here it is, playing records and making me enjoy it a lot