I'd offer two observations. 1) I can frost the bottom of a glass beaker by cleaning dirty parts in a fairly short amount of time. 2) Plastic beakers used in a high power industrial unit have shown minimal damage.

So, I think there's significant risk here, but also the potential of cleaning otherwise uncleanable records. What I'd do is immerse half of a record you don't want or care about, and run it for an hour or so. Play it and look for 0.5 revolution sound changes. You may be able to establish some audible damage threshold, then set a maximum cleaning time of a hundredth or thousandth of that. Also listen for problems at all different time periods, since ultrasonic cleaners tend to produce standing waves and may clean far better in one part of the tank, than others.

It's tough to diy a cleaner, and there are many inexpensive imports on the market now. For diy you need some fairly large piezoelectric disks, and a suitable high voltage/high current generator. There are only a couple circuit on the web, and they're pretty poor. I don't think the mist humidifiers have a large enough disk to accomplish much. BTW, never use one of those if you own LPs and tts, good cameras and lenses, or much of anything else you value. The white water deposits are ruinous.

So, I think there's significant risk here, but also the potential of cleaning otherwise uncleanable records. What I'd do is immerse half of a record you don't want or care about, and run it for an hour or so. Play it and look for 0.5 revolution sound changes. You may be able to establish some audible damage threshold, then set a maximum cleaning time of a hundredth or thousandth of that. Also listen for problems at all different time periods, since ultrasonic cleaners tend to produce standing waves and may clean far better in one part of the tank, than others.

It's tough to diy a cleaner, and there are many inexpensive imports on the market now. For diy you need some fairly large piezoelectric disks, and a suitable high voltage/high current generator. There are only a couple circuit on the web, and they're pretty poor. I don't think the mist humidifiers have a large enough disk to accomplish much. BTW, never use one of those if you own LPs and tts, good cameras and lenses, or much of anything else you value. The white water deposits are ruinous.

Hi there...

How interesting!! I am busy with a very similar project.

I got hold of an old Whaledent Ultrasonic cleaner used by dentists.

I tried the unit by holding a record halfway suspended in the unit with a chopstick. It does work.

Use a quality detergent but only add as much until water is slightly slippery to the touch. Dont add loads of detergent - wont work - only have to act as a wetting agent.

I am going to use a over rotisary motor (spit griller) - 2 rpm.

GD

How interesting!! I am busy with a very similar project.

I got hold of an old Whaledent Ultrasonic cleaner used by dentists.

I tried the unit by holding a record halfway suspended in the unit with a chopstick. It does work.

Use a quality detergent but only add as much until water is slightly slippery to the touch. Dont add loads of detergent - wont work - only have to act as a wetting agent.

I am going to use a over rotisary motor (spit griller) - 2 rpm.

GD

I'm interested in you progress, but also worry about damage. It may work fine with vinyl, as the pliability of the material may prevent small pieces from being chipped off. The suggested test should tell you something.

One method I've considered is CO2 snow cleaning. A little expensive and bulky but might work quite well - http://www.co2clean.com/index.html

I'm tempted to rent a unit and try it.

Sheldon

One method I've considered is CO2 snow cleaning. A little expensive and bulky but might work quite well - http://www.co2clean.com/index.html

I'm tempted to rent a unit and try it.

Sheldon

Hello again!

The main reason I chose to use this method, is that a friend of mine have done it this way for years. But he has done it the hard way, turning one record a 1/4 turn every 5 minutes or so. Never heard any complaint from him though, only praise.

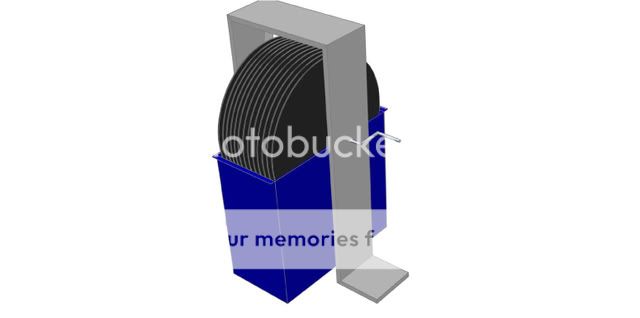

Anyhow, as the project goes on, I found out that it would be a good idea to use a ball bearing on one of the side's, and this is how it turned out to be:

And a new wheel, with slightly different color

With spacer's and axel:

Lars

The main reason I chose to use this method, is that a friend of mine have done it this way for years. But he has done it the hard way, turning one record a 1/4 turn every 5 minutes or so. Never heard any complaint from him though, only praise.

Anyhow, as the project goes on, I found out that it would be a good idea to use a ball bearing on one of the side's, and this is how it turned out to be:

And a new wheel, with slightly different color

With spacer's and axel:

Lars

I gave my idea of using an ultrasonic cleaner to clean vinyl to Mr. Lars.

There has been a few comments on the posibility of eroding the microgrooves in the vinyl. I contacted Branson (a major manufacturer of ultrasonic cleaners) and got this in reply:

"Dear Mr. Kise

You are the expert of cleaning LP’s in an ultrasonic bath. You know whether it has damage the grove or not.

In general the statement is correct. Ultrasonic cleaning is an aggressive method of cleaning as you are bombarding a surface with molecule. Some surfaces exposed long time to ultrasonics can erode. The aluminum foil is an example. But it only eroded the aluminum when the foil is thinner than 50 microns.

In general 40 kHz used like you do on plastics will not erode a surface; if it did you should have noticed it.

Yes, by stirring the liquid you will reduce the efficiency, but sometimes you need to stir or rotate or recirculating the liquid. For industrial applications where these additional forces are applied to the product we use a more density ultrasonics to overcome these reductions.

Slow rotation of discs will not disturb the ultrasonics.

Best regards

Wim van der Wal

Sales & Marketing Manager Commercial Products

Europe, Africa & Middle East

Branson Ultrasonics BV

Vlierberg 26A

NL-3755 BS Eemnes

There has been a few comments on the posibility of eroding the microgrooves in the vinyl. I contacted Branson (a major manufacturer of ultrasonic cleaners) and got this in reply:

"Dear Mr. Kise

You are the expert of cleaning LP’s in an ultrasonic bath. You know whether it has damage the grove or not.

In general the statement is correct. Ultrasonic cleaning is an aggressive method of cleaning as you are bombarding a surface with molecule. Some surfaces exposed long time to ultrasonics can erode. The aluminum foil is an example. But it only eroded the aluminum when the foil is thinner than 50 microns.

In general 40 kHz used like you do on plastics will not erode a surface; if it did you should have noticed it.

Yes, by stirring the liquid you will reduce the efficiency, but sometimes you need to stir or rotate or recirculating the liquid. For industrial applications where these additional forces are applied to the product we use a more density ultrasonics to overcome these reductions.

Slow rotation of discs will not disturb the ultrasonics.

Best regards

Wim van der Wal

Sales & Marketing Manager Commercial Products

Europe, Africa & Middle East

Branson Ultrasonics BV

Vlierberg 26A

NL-3755 BS Eemnes

Well, here we go again.

I have had problems thinking what to do about the connection/transmission between the axel and the large wheel.

This is the solution I came up with, so far.

(if any of you has another solution, don't hesitate to give it to me )

)

I only squeezed a tube and did the same thing with the axel:

Not the prettiest solution, but it works.

It has to come on and off in a easy way, I don't want it to be complicated. With 10 or 15 records on it, it will be quite heavy so...

The other side:

Lars

I have had problems thinking what to do about the connection/transmission between the axel and the large wheel.

This is the solution I came up with, so far.

(if any of you has another solution, don't hesitate to give it to me

I only squeezed a tube and did the same thing with the axel:

Not the prettiest solution, but it works.

It has to come on and off in a easy way, I don't want it to be complicated. With 10 or 15 records on it, it will be quite heavy so...

The other side:

Lars

Cal Weldon said:How are you preventing the LP's from spinning on the axle?

This is how Cal, and it's not actually spinning, with the 1 turn per 4 minutes ratio

Lars

240z4u said:Consider me subscribed!

Its neat to see someone thinking outside the normal solution.

Your acrylic work is amazing, great craftsmanship!

Evan

Thank you very much Evan.

I hope this inspires people to try to make their own. I really has belief in this project, and can already confirm that the records becomes very clean indeed.

More pictures coming soon.

Regards

Lars

While I must applaud the ingenuity, I have to offer a voice of caution about the use of alcohol in the cleaning solution.

Ultrasonics are commonly used in laboratories to aid the solvation of substances that are difficult to dissolve. I would fear that the ultrasonic bath might help the alcohol dissolve components of the vinyl.

A little alcohol in a solution used in an Okki Nokki will not do much harm, but it could be very damaging in conjunction with the ultrasonic effect.

I have no direct evidence to support what I am saying - but I would be very nervous about using alcohol in the cleaning solution.

Ultrasonics are commonly used in laboratories to aid the solvation of substances that are difficult to dissolve. I would fear that the ultrasonic bath might help the alcohol dissolve components of the vinyl.

A little alcohol in a solution used in an Okki Nokki will not do much harm, but it could be very damaging in conjunction with the ultrasonic effect.

I have no direct evidence to support what I am saying - but I would be very nervous about using alcohol in the cleaning solution.

Very lovely, Sclalars!

You are doing what I have been wondering about ever since I first saw an ultrasonic cleaner. The problem with that cleaner was that it was used as a degreaser with freon, initially, and later a more environmentally friendly liquid. This setup would have destroyed the vinyl for sure.

Good going. You have me at the edge of my seat

You are doing what I have been wondering about ever since I first saw an ultrasonic cleaner. The problem with that cleaner was that it was used as a degreaser with freon, initially, and later a more environmentally friendly liquid. This setup would have destroyed the vinyl for sure.

Good going. You have me at the edge of my seat

I have no direct evidence to support what I am saying -

Thanks for making that clear. I have used Isoprop in 50% solution to clean records for the last 50 years, and have yet to encounter a record damaged through the solution.

Baxthorpe said:While I must applaud the ingenuity, I have to offer a voice of caution about the use of alcohol in the cleaning solution.

Ultrasonics are commonly used in laboratories to aid the solvation of substances that are difficult to dissolve. I would fear that the ultrasonic bath might help the alcohol dissolve components of the vinyl.

A little alcohol in a solution used in an Okki Nokki will not do much harm, but it could be very damaging in conjunction with the ultrasonic effect.

I have no direct evidence to support what I am saying - but I would be very nervous about using alcohol in the cleaning solution.

I am curious to know what makes you nervous about using alcohol if you have no direct evidence? I have a buddy who swears by alcohol pads to clean his albums.

dnsey said:Beautifully constructed!

For the removable shaft drive, why not cut slots in the outer tube, and fit a short pin in the inner.

Yesss, that's the the way to do it, or at least something similar. I did try to remove the metal tube, and just made a split in the acrylic tube, and it was a success

Thanx dnsey!

Shaun said:Very lovely, Sclalars!

You are doing what I have been wondering about ever since I first saw an ultrasonic cleaner. The problem with that cleaner was that it was used as a degreaser with freon, initially, and later a more environmentally friendly liquid. This setup would have destroyed the vinyl for sure.

Good going. You have me at the edge of my seat

Thank you Shaun!

Here is my first idea of a washer. A hand turned one:

Would probably work also, and are easy to make.

Lars

audio-kraut said:

Thanks for making that clear. I have used Isoprop in 50% solution to clean records for the last 50 years, and have yet to encounter a record damaged through the solution.

Isoprop combined with distilled water is the most common prescription to clean records here in Norway, so I'm not that anxious about this issue.

Lars

The mixture is 7 parts of destilled water (or norwegian spring water!), 1 part of alcohol and a little synthetic detergent. Just enough to break up the surface.

After we have heard som concerns about erroding the vinyl, we will do some long term testing to see.

Will you let me do the testing Lars?

After we have heard som concerns about erroding the vinyl, we will do some long term testing to see.

Will you let me do the testing Lars?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- I made myself a record cleaner