1 lb copper bar. 1 pound copper bullion. .999 fine - eBay (item 180526683194 end time Sep-26-10 18:23:24 PDT)

1lb copper block?

this also have 8oz ones...

Would these make good heatsinks for lm3875 dual mono? I noticed Peter Daniels likes to use copper blocks on his amps, and these seem pretty cheap. Any thoughts?

1lb copper block?

this also have 8oz ones...

Would these make good heatsinks for lm3875 dual mono? I noticed Peter Daniels likes to use copper blocks on his amps, and these seem pretty cheap. Any thoughts?

Did it before with similar copper blocks. It just works, but aside of looking fancy there is no benefit.

Did it before with similar copper blocks. It just works, but aside of looking fancy there is no benefit.

Did you compare the sound to aluminum😀

1 pound of copper bar is pretty small for an unfinned block for heatsink though.

I remember seeing full-copper finned fanned heatsinks weighing 1kg for computer use.

I remember seeing full-copper finned fanned heatsinks weighing 1kg for computer use.

your 1lb of copper is about 3.5cub in.

Looking at the pic, I'll guess that the copper block is ~2.5in long.

@$6.5 +4.5post that 1lb block is costing you >$24,000.00 per tonne

Looking at the pic, I'll guess that the copper block is ~2.5in long.

@$6.5 +4.5post that 1lb block is costing you >$24,000.00 per tonne

jordyyy:

I've built 4 LM3875 Gainclones, each with a 5" * 2.5" * 0.75" copper heatsink. The copper blocks work well but are a royal pain to drill; you gotta go verrry slowly or you'll break your bits.

Regards,

Scott

I've built 4 LM3875 Gainclones, each with a 5" * 2.5" * 0.75" copper heatsink. The copper blocks work well but are a royal pain to drill; you gotta go verrry slowly or you'll break your bits.

Regards,

Scott

Copper will make NO DIFFERENCE to the sound AT ALL. It is purely the temperature of the output devices that is of concern.

Try to keep them below 60 Degrees C for reliability. Some people say 80 Degrees C is OK but electrolytics start to dry out pretty quickly under elevated temperatures.

With all heatsinks you are after surface area so a block will have nothing like the surface area of a finned heatsink. If you can saw a few channels into the block to make it into a conventional heatsink topography then you are talking. Copper is a better conductor of heat than alluminium.

Try to keep them below 60 Degrees C for reliability. Some people say 80 Degrees C is OK but electrolytics start to dry out pretty quickly under elevated temperatures.

With all heatsinks you are after surface area so a block will have nothing like the surface area of a finned heatsink. If you can saw a few channels into the block to make it into a conventional heatsink topography then you are talking. Copper is a better conductor of heat than alluminium.

Last edited:

If you want to get what copper has to offer you have to focus on what that is. Copper has higher thermal conductivity but much lower thermal mass. In other words, copper is great in a well calculated amount for immediately spreading heat from a small area to a larger one so that the resistance of the Second interface can be made less significant. A the package you're still limited by the area of the thermal pad, and to get absolute maximum thermal performance you should already be exploring things like electrically non-insulated connections from package to sink, otherwise the copper probably wont do much of anything. Copper is great for very small heatsinks where high thermal mass is impossible anyway. A sink with lots of aluminum in it will stay at the same temperature for longer than one made entirely of copper, increasing thermal stability over the copper sink no matter what is the average temp of the sink or ambient air.

Last edited:

Also, you would do well to paint the copper matte black (except where the transistors are mounted), this will significantly improve heat radiation.

If you're trying to get low noise, you'll want it as cold as possible. You could pot low signal circuits in epoxy or silicone, encase them in metal, then mount them to a small Peltier. Thermal noise generally doesn't do much with power circuits, but they shouldn't reach 60C unless they're running at high load.Try to keep them below 60 Degrees C for reliability. Some people say 80 Degrees C is OK but electrolytics start to dry out pretty quickly under elevated temperatures.

Just use heatsinks available from computer stores, they easily deal with 100w of heat, probably more since power semiconductors are less sensitive to temperature than high speed VLSI. Realistically, they would be enough for most DIY since 100w of dissipation is a lot for a single transistor unless you're dealing with many kW of power.

1 lb copper bar. 1 pound copper bullion. .999 fine - eBay (item 180526683194 end time Sep-26-10 18:23:24 PDT)

1lb copper block?

this also have 8oz ones...

Would these make good heatsinks for lm3875 dual mono? I noticed Peter Daniels likes to use copper blocks on his amps, and these seem pretty cheap. Any thoughts?

You need more than thermal mass. You also need radiation capability. Mass just takes time to heat up but doesn't get rid of the heat. IOW you want modest mass with lots of fins. Aluminum is fine for this task as it is cheap and extrudes nicely.

G²

I have been thinking about a similar use for some copper bars I have.

I think if you pursue Andrew E's (unusual number of "Andrews" on the previous page!) reasoning it might be profitable. What I am going to do is this.

(a) mount the power transistors on the copper but

(b) get some sheet Aluminium, say, 2-3mm think and bolt several sheets to the copper block. These will need to be bent, formed etc. And heat sink compound between the sheets. All good common sense stuff.

This means you can take advantage of the ability of the copper to conduct the heat away from the transistor quickly. The Al sheet then provides the appropriate larger radiating area to the air.

Bit of drilling, cutting and bolting involved but that's what we're here for.

My bars are 10mm bus bars from an electrical installation somewhere (a friend got them).

They will be the heat sinks for a class A amp. Given that copper has about twice the thermal conductivity as Al and that the average power tranny heatsink is 5mm I am interested to see if they do keep the package cooler given an equivalent radiating area for the Al fins.

Anyway it will be fun........

I think if you pursue Andrew E's (unusual number of "Andrews" on the previous page!) reasoning it might be profitable. What I am going to do is this.

(a) mount the power transistors on the copper but

(b) get some sheet Aluminium, say, 2-3mm think and bolt several sheets to the copper block. These will need to be bent, formed etc. And heat sink compound between the sheets. All good common sense stuff.

This means you can take advantage of the ability of the copper to conduct the heat away from the transistor quickly. The Al sheet then provides the appropriate larger radiating area to the air.

Bit of drilling, cutting and bolting involved but that's what we're here for.

My bars are 10mm bus bars from an electrical installation somewhere (a friend got them).

They will be the heat sinks for a class A amp. Given that copper has about twice the thermal conductivity as Al and that the average power tranny heatsink is 5mm I am interested to see if they do keep the package cooler given an equivalent radiating area for the Al fins.

Anyway it will be fun........

Last edited:

It might work. But imho it looks stupid because you need surface area to radiate the heat. If you build it with this block as heatsink it will only look like you don't know what you're doing. If you want something cheap: take apart an old PC power supply and use it's heatsinks and fan.

I want something aesthetically pleasing and cheap (and works well!). Which isn't so easy to do. Im a product design student... So, basically I am looking for good options, and I'm curious about the freedom copper blocks haha. If they are not a good option, its no problem, there are other heat sinks, and ways to hide the heat sinks =) I am getting mixed review on them, so ill keep my options open. I am waiting to here back about the thickness of materials our laser cutter can cut at school, which will determine the chassis ill make, which will alloy me to choose which heat sink to use with my design.

Another possibility here if the block is of the correct dimensions, bore a hole or two through the block from side to side, making sure that you leave an area where holes from a perpendicular face can be drilled for mounting your active device(s). Make these bore holes of a size that you can solder copper pipe into. Then you use this block with a pump and external heat radiator. Voila!, a heat exchanger.

Dave

Dave

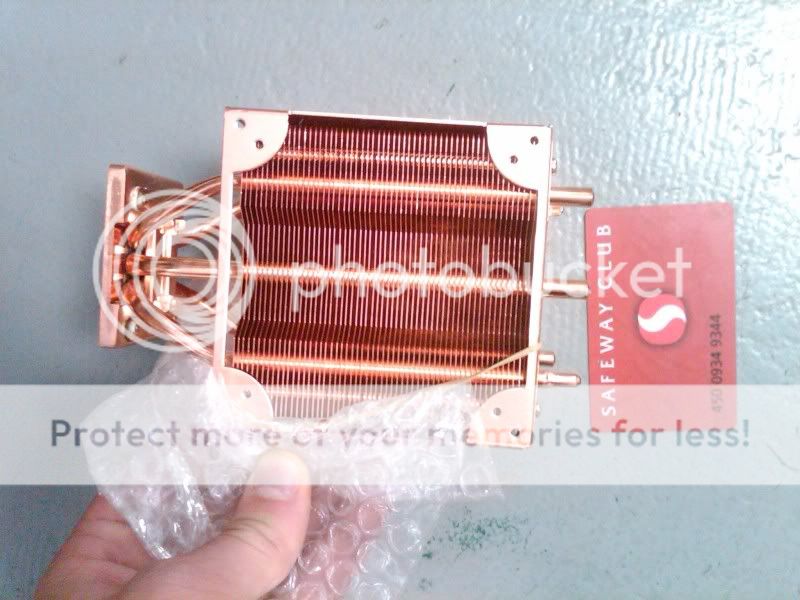

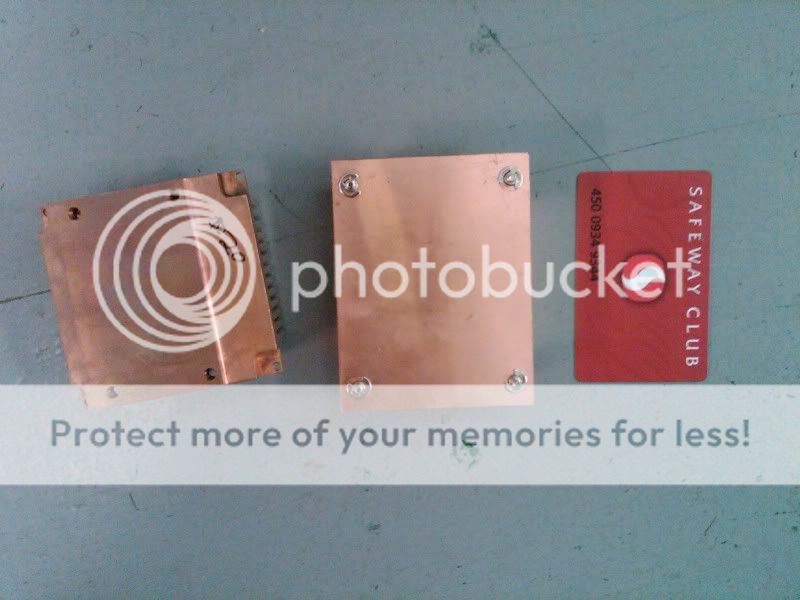

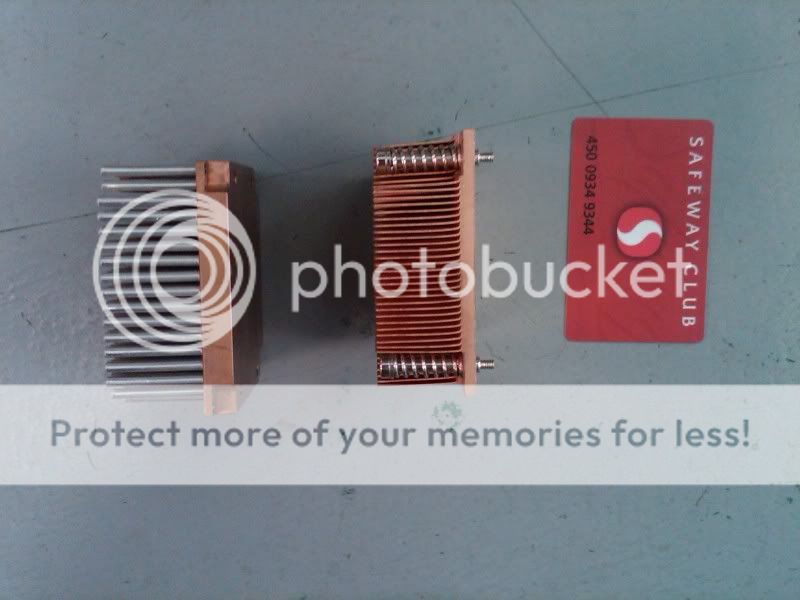

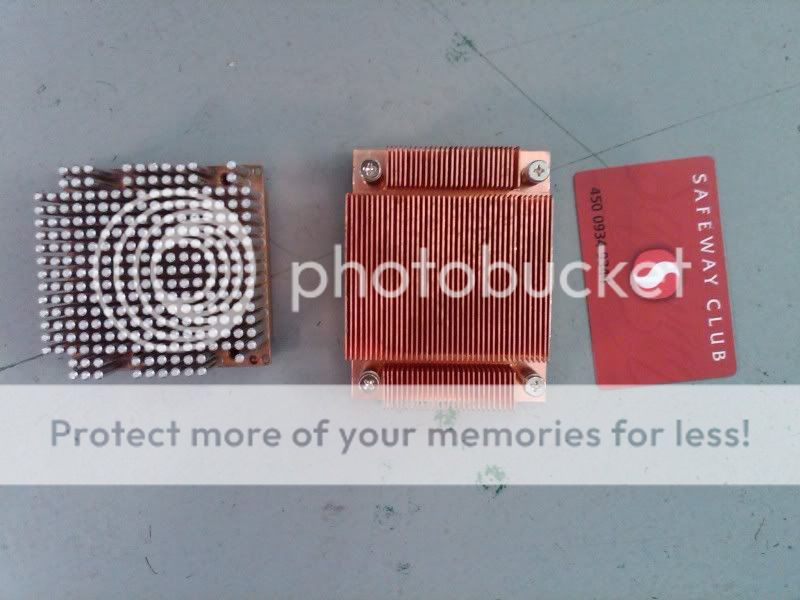

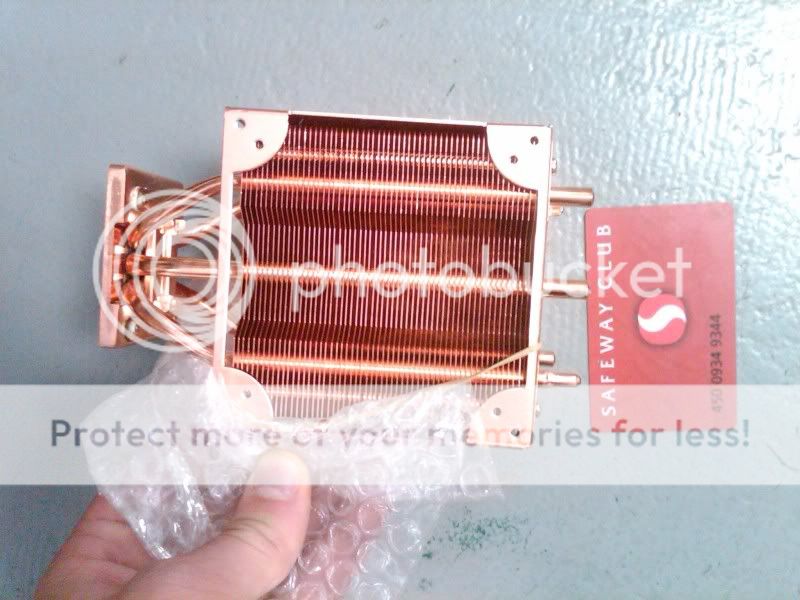

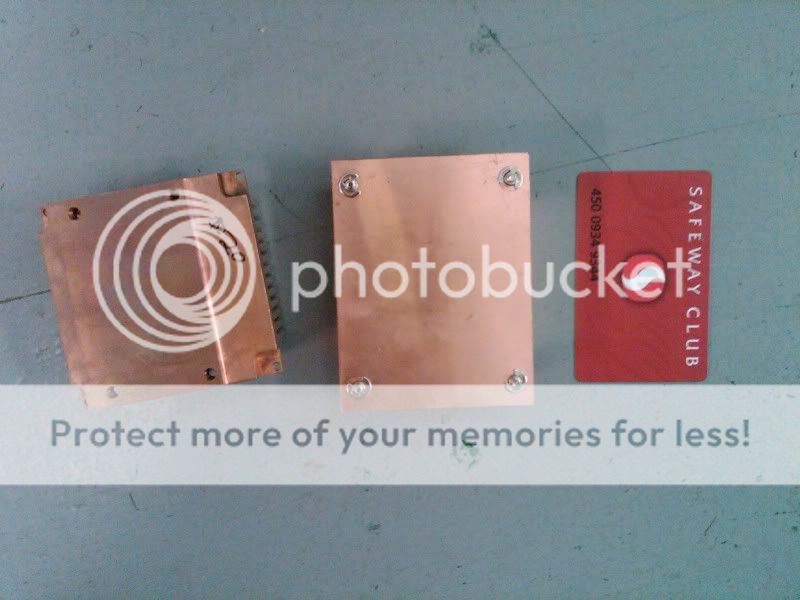

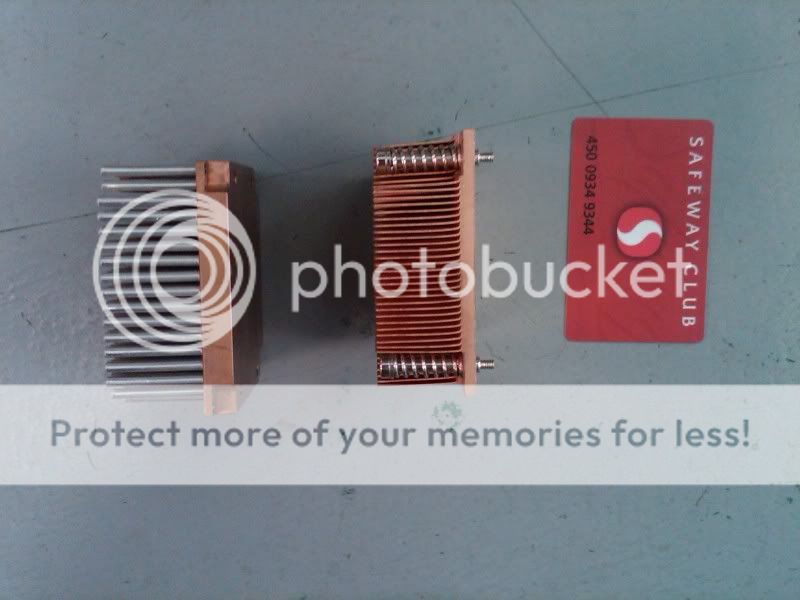

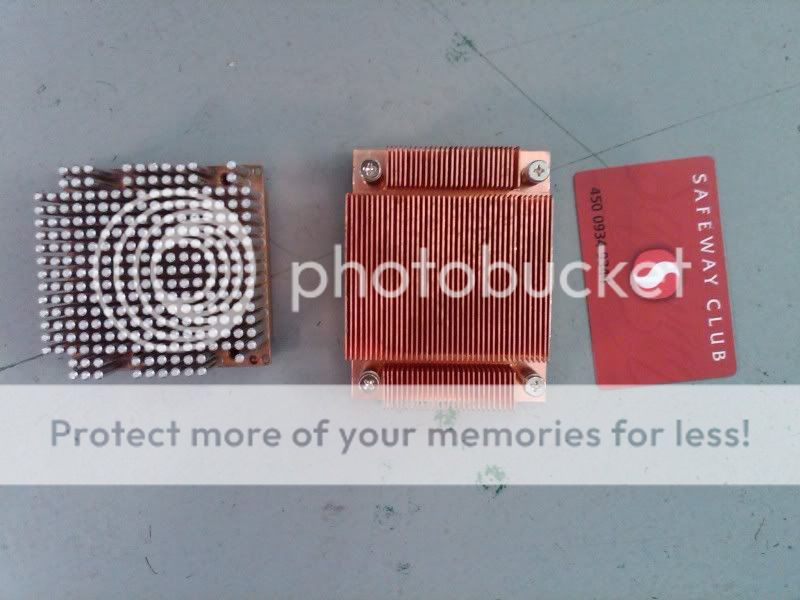

I found these at a recycle electronics store, would any of these be good for 2 lm3875 chips or would i need more heat sink? The first 2 pictures are a heat pipe which is $25. The other 2 heatsinks are $20 and $30. The safeway club card is for size reference, same size as a credit card.

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- would this make a good copper heatsink??