Interesting.

I'd argue that Qms is fairly irrelevant in quantifying the performance of a driver.

The Q-factors are only measured at Fs, where the cone is acting as a piston, resonating

as a mass on a spring. At that frequency, Qes dominates for >90% of drivers.

Chris

Hi,

Qes only dominates Qts if Qms is relatively high. I had

a look at Zaphs 5.5" drivers and the most common value

of Qms is around 3. Which reduces Qts to about 0.5

when Qes is about 0.6, which is not irrelevant.

Lowest Qms is about 2, and high is say 5 to 10.

For sure high Qms is nothing to worry about.

rgds, sreten.

Last edited:

Selenium WPU 1507 15" PA woofer. I use them in Altec 825 and 210 enclosures. Good fit.

Qms: 27

https://www.lautsprechershop.de/pdf/selenium/selenium_wpu1507.pdf

Qms: 27

https://www.lautsprechershop.de/pdf/selenium/selenium_wpu1507.pdf

For the most part, it is desired that the Qms does not contribute significantly to the overall Qts. In the case of the Dipole15 and LO15, Qms is high because of the kapton voice coil former. If we were to wind the same coil on an anodized aluminum former, the Qms would be lower. It would then play more of a roll in the overall Qts. The ideal situation lets the motor and Qes handle all the damping. This of course means that you need linear motor strength throughout the travel. Otherwise Qts will go up the farther away from center the coil moves.

For the most part, it is desired that the Qms does not contribute significantly to the overall Qts. In the case of the Dipole15 and LO15, Qms is high because of the kapton voice coil former. If we were to wind the same coil on an anodized aluminum former, the Qms would be lower. It would then play more of a roll in the overall Qts. The ideal situation lets the motor and Qes handle all the damping. This of course means that you need linear motor strength throughout the travel. Otherwise Qts will go up the farther away from center the coil moves.

Qms is defined as the mechanical damping at the spring-mass resonance of the cone. How does VC former material contribute?

Chris

Hi chris661,

The idea behind it is that the Aluminium former, or other conductive materials, suffers from losses: Eddy currents. Since the aluminium VC former is not part of the electrical circuit these losses are (mainly) reflected in an increase in mechanical resistance and lower the Qms.

Cheers,

Djim

The idea behind it is that the Aluminium former, or other conductive materials, suffers from losses: Eddy currents. Since the aluminium VC former is not part of the electrical circuit these losses are (mainly) reflected in an increase in mechanical resistance and lower the Qms.

Cheers,

Djim

Last edited:

from reading all this, I have a question.

My woofers have a LOW Qms (Qms #one is 2.00, the #two 1.40).

Also Qes is low (#One 0.44; #two 0.20). And the Fres is unequal too: #1 52, #2 something like 38-42.

Although on an open baffle simulator the sound pressure equates to almost the same - within a dB 😕

What should I do to get them more equal. (I think) I like a higher Qms; I am afraid I cannot increase the Qes.

Might be a stupid question all together.

My woofers have a LOW Qms (Qms #one is 2.00, the #two 1.40).

Also Qes is low (#One 0.44; #two 0.20). And the Fres is unequal too: #1 52, #2 something like 38-42.

It is a 38 cm speaker, paper cone. Paper surround (3 plies) & Alnico magnet. Built in 1956 or so.

So they differ.Although on an open baffle simulator the sound pressure equates to almost the same - within a dB 😕

What should I do to get them more equal. (I think) I like a higher Qms; I am afraid I cannot increase the Qes.

Might be a stupid question all together.

You could chip away some magnet material 😉I am afraid I cannot increase the Qes

No seriously, their exact placement (in the room) is most likely contributing to a lot more than an 1 dB difference, so not really something you should worry about.

Johan

I was surprised by the open baffle simulation, seeing the big 'differences' in parameters; but as I read in this thread, the parameters are only based on one frequency: the resonance.

There is something evasive going on.

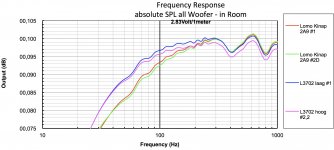

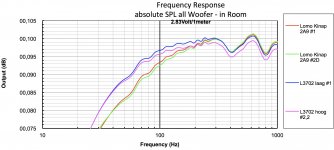

Now I liked the L3702 very much in the room, but it only started to shine at louder levels. Then the sound was really what I preferred: on voices, singers. It has Qms 5,12, Qts 0,56.

On low level detail the 2A9 shines, it gives more depth and background, small music details, but bass lacks on open baffle. So needs more correction. I dropped the OB idea [for now].

I plan to go closed box.

Question: would the difference in parameters also be negligable in a closed box?

It implies those big differences in parameters do not say much.

What if I make a pertinax spider? Should increase the Qms I expect.

There is something evasive going on.

Now I liked the L3702 very much in the room, but it only started to shine at louder levels. Then the sound was really what I preferred: on voices, singers. It has Qms 5,12, Qts 0,56.

On low level detail the 2A9 shines, it gives more depth and background, small music details, but bass lacks on open baffle. So needs more correction. I dropped the OB idea [for now].

I plan to go closed box.

Question: would the difference in parameters also be negligable in a closed box?

Found a calculator. Targeting a Qts of the box of 0,6, I get: #1 - 50 liters, F3 119, Fb 98; #2 - 46 liters, F3 122, Fb 101.

That also is a small difference in my opinion.It implies those big differences in parameters do not say much.

What if I make a pertinax spider? Should increase the Qms I expect.

Last edited:

There's something upside down in this discussion of Q that misses the point. That may be why this discussion is so unfocused. Granted, Q is inherent in the T/S analysis. But that alone does not make it a useful way to think about driver SQ because Qms is an umbrella for a number of design factors that should be explored individually.

The essential question is what driver follows the input signal best, both transiently and alternating-steady-state. Damping is a loss and can't be considered beneficial per se. So drivers with heavy cone assemblies* and enough damping to lower Qms aren't smart even if they seem to sim well... which is essentially a steady-state condition.

But Qes arises from error signals (AKA back EMF) and, I would intuit, isn't lossy except vis a vis cone error. Cone motion at Fs is error and high Qes is beneficial in controlling it but high mechanical damping isn't helpful.

B.

*which is the trend, given the marketing pressure to come up with out of this world power handling specs with VCs wound with 14 gauge wire... which may be reason to favour the approach found in legacy drivers... which is exactly what Joachim Gerhard of Audio Physik quoted in post #6 is saying

The essential question is what driver follows the input signal best, both transiently and alternating-steady-state. Damping is a loss and can't be considered beneficial per se. So drivers with heavy cone assemblies* and enough damping to lower Qms aren't smart even if they seem to sim well... which is essentially a steady-state condition.

But Qes arises from error signals (AKA back EMF) and, I would intuit, isn't lossy except vis a vis cone error. Cone motion at Fs is error and high Qes is beneficial in controlling it but high mechanical damping isn't helpful.

B.

*which is the trend, given the marketing pressure to come up with out of this world power handling specs with VCs wound with 14 gauge wire... which may be reason to favour the approach found in legacy drivers... which is exactly what Joachim Gerhard of Audio Physik quoted in post #6 is saying

Last edited:

The essential question is what driver follows the input signal best, both transiently and alternating-steady-state.

Damping is a loss and can't be considered beneficial per se. So drivers with heavy cone assemblies* and enough damping to lower Qms aren't smart even if they seem to sim well... which is essentially a steady-state condition.

Ben, thanks. This reasoning I though would lead me into the direction of a pertinax spider: it can be made much less stiff than a treated cloth surround.

When I re-spidered  my Lowther driver I saw the the stock replacement part is foam and is very 'sloppy'. I choose a natural rubber version that was a little bit heavier and even more sloppy. Sound is gorgeous. (Lowther PM2 is also very low Qts by the way).

my Lowther driver I saw the the stock replacement part is foam and is very 'sloppy'. I choose a natural rubber version that was a little bit heavier and even more sloppy. Sound is gorgeous. (Lowther PM2 is also very low Qts by the way).

my Lowther driver I saw the the stock replacement part is foam and is very 'sloppy'. I choose a natural rubber version that was a little bit heavier and even more sloppy. Sound is gorgeous. (Lowther PM2 is also very low Qts by the way).

my Lowther driver I saw the the stock replacement part is foam and is very 'sloppy'. I choose a natural rubber version that was a little bit heavier and even more sloppy. Sound is gorgeous. (Lowther PM2 is also very low Qts by the way).So a stiff spider is not needed.

Caveat:

But I cannot say (design, set a goal) what the stiffness is of a spirally formed piece of pertinax; can't measure. Is is just old school work where people like Rullit are using those old techniques again.

I made a pertinax spider in 2012 for a subwoofer: the outcome was a Fres on both subwoofer speakers of 29 Hz. So my artwork worked.

I made a pertinax spider in 2012 for a subwoofer: the outcome was a Fres on both subwoofer speakers of 29 Hz. So my artwork worked.

If I recall, Rice and Kellogg used spiral spiders - which is where the name "spider" comes from. The point is that the spiral is a way of making a very long flexible support wrapped in a small space. But starched cloth also serves as a dust cover.

Data point: I recently re-surrounded my legacy Stephens 150W woofer which had an Fs of 21 Hz (don't ask me why I did it, too embarrassing to say). With a nice modern looking rolled rubber-like surround that went to 34 Hz. With a new treated-cloth surround it went to about 27 Hz.

Instead of comparing and rating drivers by Q, I think we need a figure of merit representing "motor force compared to mass". The bigger the better.

B.

Data point: I recently re-surrounded my legacy Stephens 150W woofer which had an Fs of 21 Hz (don't ask me why I did it, too embarrassing to say). With a nice modern looking rolled rubber-like surround that went to 34 Hz. With a new treated-cloth surround it went to about 27 Hz.

Instead of comparing and rating drivers by Q, I think we need a figure of merit representing "motor force compared to mass". The bigger the better.

B.

Instead of comparing and rating drivers by Q, I think we need a figure of merit representing "motor force compared to mass". The bigger the better.

B.

Agree.

My 2A9 has the 'biggest' Alnico magnet assembly you can find: at some 12 Kg it is hefty. And it does give a lot of control. But the control eats lows (like Zeus eats his children).

The big advantage of the monitor from the 50-ies is that the whole cone assembly comes loose and can be replaced with a drop-in in minutes. Now that is pro.

That makes it easy to fiddle with.

I sold the good sounding L3702's (not a perfect pair). Don't ask either. That is the strange thing about tha hobby.

Instead of comparing and rating drivers by Q, I think we need a figure of merit representing "motor force compared to mass". The bigger the better.

B.

We have one. It's called sensitivity, and higher is only better if it suits your design goals.

Right and in keeping with the Lotus versus Corvette metaphor. But then doesn't "sensitivity" miss why the Lotus is better*?We have one. It's called sensitivity, and higher is only better if it suits your design goals.

So, shouldn't damping or something needs to be added to the index to characterize a driver that follows a transient signal? Perhaps sensitivity times Qms?

Triode_al is right to point out how the various parameters interact esp when a "good" parameter (like BL) leads to bad results. Or the interaction of FR and driver diameter. Seems ridiculous to me that we expect a properly designed Rice-Kellogg device to produce a flat FR without massaging the FR using EQ.

B.

*disclosure: I'm biased, ahem, ahem

1) you can do nothing. You have what you have.My woofers have a LOW Qms (Qms #one is 2.00, the #two 1.40).

Also Qes is low (#One 0.44; #two 0.20). And the Fres is unequal too: #1 52, #2 something like 38-42.

It is a 38 cm speaker, paper cone. Paper surround (3 plies) & Alnico magnet. Built in 1956 or so.What should I do to get them more equal. (I think) I like a higher Qms; I am afraid I cannot increase the Qes.[/I]

Way back then speakers were **stiff** and that´s an understatement.

You have low(ish) resonance frequency only because those edges and suspensions have been massaged to death ... talk about speaker loosening 🙂

Want to loosen the stiff one?

Cool, just play some music LOUD (some 10W RMS) for 10/15 years and it will catch up 🙂

2) you want modern speaker specs? ... buy modern speakers 😉

You want old speakers? fine with me, but accept their idiosincracies.

Like driving a Ford T: fine, just don´t complain about the low MPG, stiff suspension, hand cranked starter and somewhat uncomfortable interior 🙂

Want some music while riding?

Cool, just don´t install a modern Audio system, I guess riding Uncle Joe in the back seat while playing some Banjo, Fiddle or Harmonica will be Vintage consistent.

Not suggesting Acoustic Guitar because you won´t hear it over the engine roar 😉

Did you notice that the 1960 Stephens driver I discussed in post #21 didn't change Fs in 50 years? Started with an Fs about 20 Hz and stayed there; hard to find a similar fabulous spec today for a light-weight cone assembly. A lovely VC with edge-wound wire.1) you can do nothing. You have what you have.

Way back then speakers were **stiff** and that´s an understatement.

You have low(ish) resonance frequency only because those edges and suspensions have been massaged to death ... talk about speaker loosening 🙂

...

I am at a loss to hear of any important advances in cone driver design between then and now for the generic Rice-Kellogg cone driver which is all but universal.

Yes, some advances of a modest sort (cone materials, eddy current coils, analysis of impedance match to the surround, labels printed on the dust cap in big white letters...) but these are not substantive improvements for subs and there's no sense using cone drivers above that band. Likely the debate about under- and over-length VCs and much else about self-evident magnet issues goes back 100 yrs.

We need alternative driver concepts like full-range plasma, not trivial improvements.

B.

Last edited:

I still don't get it. How can a driver with T/S, constructed with more or less the same size and shape, and even as far as the same cone material as another driver with the same parameters have a different frequency response, or the one sound good and the other bad? Surely physics says that with that spring/damper system, and that rigidity, and that much copper wire over that diameter and length, in that magnet must sound the same when reproduced?

My guess is that no-name driver with identical physical properties to big-name driver only sounds bad because it doesn't sport the logo.

My guess is that no-name driver with identical physical properties to big-name driver only sounds bad because it doesn't sport the logo.

I do not subscribe to that sort of conspiracy cynicism, magazine reviews aside....My guess is that no-name driver with identical physical properties to big-name driver only sounds bad because it doesn't sport the logo.

Ceteris paribus*, as we say, is a dead-end argument since one person's equal is another person's not quite equal.

But since my old post here, I've seen descriptions of a few cone-like drivers that may materially advance the art.

B.

*all else equal

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Woofer with high Qms