Not with 2382's or 2405's in it.Never heard Drew Daniels's monster JBL system. Maybe that's the Holy Grail...

Wooden mid horns can be quite rewarding to make yourself.

I went from a small metal exponential midhorn with a compression driver to wooden tractrix midhorn with a cone driver and the improvement in clarity and loss of tunnel sound was amazing.

I went from a small metal exponential midhorn with a compression driver to wooden tractrix midhorn with a cone driver and the improvement in clarity and loss of tunnel sound was amazing.

Its not difficult, and no special tools required

You only need good working space, and its a hell of dusty mess

oh, btw

If you are interested, and know how to handle glassfiber laminate, I have "plans" fore doing an easy mold fore elliptical horn, with complex rounded mouth shapes

Afterwards, if you like, It will also be fairly easy to do a 2-part professional mold

But I hate polyesther

You only need good working space, and its a hell of dusty mess

oh, btw

If you are interested, and know how to handle glassfiber laminate, I have "plans" fore doing an easy mold fore elliptical horn, with complex rounded mouth shapes

Afterwards, if you like, It will also be fairly easy to do a 2-part professional mold

But I hate polyesther

Last edited:

Mentioning cheese, you just made me remember

You can make this cheese cutting bow like thing

A big one ofcourse

If you put a battery on the string it will get hot

Then you can cut solid polystyrene blocks pretty accurately by following two carefully alligned shape pattern plates

The hard ones fore flooring will be tough enough without any further treatment

Its easy to glue solidly together with polyurethane glue

If you want it to be tougher, paint it, and it will take epoxy laminating

Or maybe ask for poly blocks in surfboards shops

But if reinforcing, I would do that part before assembling

If you want it to be heavier and more durable, put it in a plywood/MDF box

If you are good, you can make some real good looking horns quite easy, and cheap

Last edited:

That's true (i.e., I could be a victim of self-deception). Though hearing differences in speakers is not exactly an extraordinary claim.

Never heard Drew Daniels's monster JBL system. Maybe that's the Holy Grail...

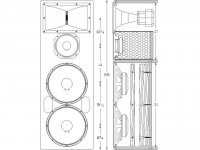

I have read that "Back in the day" Drew Daniels most popular JBL speaker used two 15" ported woofers, a 10" midrange (JBL 2125 or 2123 ? ) and a compression driver horn tweeter.

I've moved away from small diameter midrange speakers to 8" - 10" almost full range drivers for a wider BW midrange, and I like the dynamics and coherence from crossovers around 80Hz and 1,500Hz. RAAL type ribbons have been the only 96+ db/watt tweeter alternative that my ears like.

Maybe speaker technology has advanced to where a dynamic midange driver can now integrate into a horn sytem.

Attachments

Where can you get wooden horns like the ones below, or at least elliptical ones (not necessary wooden either) for compression drivers? 400hz or below cf. Only ones ive seen are Fostex H400 and the Pi speakers ones, but at ridiculous prices... Around 600 usd a pair is more realistic to me.

In reference to Pi Speakers, I think you must be talking about our wood tweeter horn, which is rather expensive at $700. Our midhorn is only a hundred bucks, not too expensive. It's pretty easy to make. The tweeter horn is more difficult because it is curved, really a work of art. All the cost is in machine time, with some assembly and finishing time afterwards too. My goal when I started making them was $400, but when we had done a few, we realized it cost nearly twice that to make them.

Here's a photo of one of our wood tweeters on top of one of our wood midranges. You can see what I mean:

Round horns are easy to make. They don't cost much at all because you can turn them on a lathe. But I've never been a fan of round horns. Elliptical and rectangular horns are more difficult, because they have to be cut on a multi-axis CNC machine. Best to go with a 5 axis machine, but you can do them on 3 axis machines with the right mounting procedures, but it takes several steps with repositioning between each one. It's trickier that way, and requires you to figure out a way to mount the part so that it remains indexed between flip operations. We do it with mounts that stay on the part until it is finished, when they are cut off like risers in a casting. Either way - 3 axis or 5 axis - you have to make hundreds of cutting passes and it takes a lot of machine time. Unless you own the machine, it costs $$$.

Our midhorn is only a hundred bucks, not too expensive. It's pretty easy to make.

I found your $700 tweeter horn no problem (Parts & Options).

But no midhorn kit at that price. Where should I be looking?

Well, yeah, you're right. Got me.

I kinda sometimes forget not everyone knows my situation since we're such a small community (we audiophiles).

My cabinetmaker died last summer, so I took the $100 flat pack kits off the shopping cart to give time for the new cabinetmaker to get them down. They were a hundred bucks when I was selling them, and they'll be available at that price again in a few months (hopefully) but now all I can do is give you the plans and let you cut your own out. But the midhorn isn't hard to make 'cause it's all flat sides.

I can still make CNC cut stuff 'cause the CNC shop guys are all still there. The new assembly guy can make my boxes and so most of my cabinets are available now, but not midhorns. Those have been on hold now for some time.

I kinda sometimes forget not everyone knows my situation since we're such a small community (we audiophiles).

My cabinetmaker died last summer, so I took the $100 flat pack kits off the shopping cart to give time for the new cabinetmaker to get them down. They were a hundred bucks when I was selling them, and they'll be available at that price again in a few months (hopefully) but now all I can do is give you the plans and let you cut your own out. But the midhorn isn't hard to make 'cause it's all flat sides.

I can still make CNC cut stuff 'cause the CNC shop guys are all still there. The new assembly guy can make my boxes and so most of my cabinets are available now, but not midhorns. Those have been on hold now for some time.

Last edited:

Beats me what you want it fore

Many 2" or 1.5" doesnt go much lower than some 1", they just play louder

A few does, but you will limit yourself to using those because of that, and not able to choose fore best sound quality no more

2" is still smallish, 75mm diaphragm if I remember it

Mostly same driver as 1.4", just with bigger exit

To me it seems obvious that such a small driver doesnt work well at lower frequency

Many 2" or 1.5" doesnt go much lower than some 1", they just play louder

A few does, but you will limit yourself to using those because of that, and not able to choose fore best sound quality no more

2" is still smallish, 75mm diaphragm if I remember it

Mostly same driver as 1.4", just with bigger exit

To me it seems obvious that such a small driver doesnt work well at lower frequency

Last edited:

Beats me what you want it fore

Most 2" doesnt go much lower than 1.5" or even some 1", they just play louder

I would study a bit more and get more experience with these things before you throw the towel, and your money

The only compresion drivers worth anything down low are probly also the most expencive japanese stuff, exstremely expencive

Ive not seen any 1" compression drivers except JBL 2426 be capable to reach 500hz, and still peform good. And the JBL has a titanium diaphragm which is a total no go for me...

You are aware that the drivers can cost up to 400-500 EUR each, and are mostly titanium, or aluminium

You will have very limited choices

You will have very limited choices

You are aware that the drivers can cost up to 400-500 EUR each, and are mostly titanium, or aluminium

You will have very limited choices

The Radian 651PB is the best compromise ive found. Aluminium with mylar suspension.

JBL 2470 1" phenolic dia , driver will go 500Hz easy and Klipschorn folks are using it down to 400hz I heard. Yamaha JA6681B will do the same. Martin Seddon (Azura Horns) has a nice plot on his 160hz LeCleach horn.It's mostly about horn. Get the plans and look for local woodworker/carpenter to build you a pair.

Also the BMS 4550 can go up to 500 Hz.

Is a 1" driver.

BMS recommended 800 Hz crossover.

But also 500 Hz can easily reached.

But also not so cheap, around 160.- Euros each.

But sound quality is excellent.

PDF Data is too big to upload.

Is a 1" driver.

BMS recommended 800 Hz crossover.

But also 500 Hz can easily reached.

But also not so cheap, around 160.- Euros each.

But sound quality is excellent.

PDF Data is too big to upload.

You are going to need to nuild your own or have someone CNC them for you. Go to audioheritage forums and so a search, there was a guy in Nth Europe who had a number of radial horns CHC'd for an HT. He may be able to help.Sooo.... do anyone know of any 2" throat wooden midhorns under 1000 usd a pair?

Or you could actually do the work and design them yourself; there are plenty of calculators available for different flare profiles.

Many 2" exit drivers are 4" diaphragms.2" is still smallish, 75mm diaphragm if I remember it

Many 2" exit drivers are 4" diaphragms.

Well, yeah it varies

A few do have 4" voicecoil, but seems to be older models

Very many 2" exits have 3" voicecoil

As do most 1.4" exits

But the Radian in question is with 3" voicecoil

Tho the older Radian top model is 4"

Whether a bigger 2" exit would sound better I dont know, but its proably not expected to go much lower than its 1.5" brother

Other than the horn size may be slightly diffferent with a bigger throat

I only say this because I expect many people may not have realised this

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Wooden mid horns