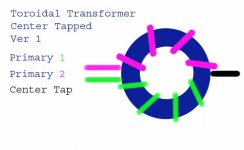

I just want to make sure which method is the correct one for winding a toroid. Which of the 2 versions I have below is the correct one? This would be used for a smps. Transformer would need to be center tapped, using 4 windings each as an example. Thanks for the help.

Version 1

Version 1

Attachments

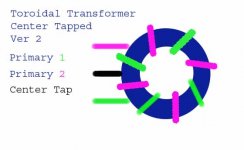

You should spread any winding evenly over the core. Therefore the second version is the one to use.

If the power is great enough and you wound as version 1, you may even blow things up!

If the power is great enough and you wound as version 1, you may even blow things up!

For low power you can use version 1 to reduce capacitance between winding at the expense of having worse coupling bwtween them and double the leakage inductance

For high power version 2 is desirable due to better coupling at high frequencies and optimum leakage inductance

To optimize the winding for high power you should also select a proper volts/turn ratio, the higher you can [less turns mean less wire resistance and less leakage inductance] but mantaining some security margin to prevent the core to saturate at high temperatures

Cores tend to have higher permeability at higher temperatures, storing more energy in the same time period, and reduced energy energy storage capaability as temperature increases so they are much easier to saturate when hot

For high power version 2 is desirable due to better coupling at high frequencies and optimum leakage inductance

To optimize the winding for high power you should also select a proper volts/turn ratio, the higher you can [less turns mean less wire resistance and less leakage inductance] but mantaining some security margin to prevent the core to saturate at high temperatures

Cores tend to have higher permeability at higher temperatures, storing more energy in the same time period, and reduced energy energy storage capaability as temperature increases so they are much easier to saturate when hot

Phasing!

If both the free ends of the windings pass through the centre of the toroid the same direction as per the drawing, they will be in phase. This is not what you want for a centre tapped winding. Apply ac between the ends of the windings and it will behave like a short cct. The beginning of the winding should go through from one side and the end should exit from the opposite side.

If both the free ends of the windings pass through the centre of the toroid the same direction as per the drawing, they will be in phase. This is not what you want for a centre tapped winding. Apply ac between the ends of the windings and it will behave like a short cct. The beginning of the winding should go through from one side and the end should exit from the opposite side.

You have drawn a center tapped inductor. If you want a transformer, you need a second set of windings (unless you want an autotransformer).

Thanks everyone. I only showed the primary winding on the above pics to make it less confusing, I know you also need secondary windings as well. I was unaware of what Circlotron stated, I had not picked up that tidbit of information before, thanks.

Yeah, I think the first drawing is not quite right - the bottom green primany winding would come out on top, not the bottom. Just curious why you need a center tapped primary.

I'm making a Push-pull smps, all the schematics I've seen need a center-tapped primary to function. At least all the higher power ones.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Winding a Transformer