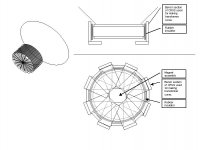

I am trying to find out a simple scheme for shielding speaker magnets. It should be easy to construct with basic tools and should be with locally available components. So i thought of using CRGO (the one used for making E and I sections of transformers). the idea is presented in the attached picture.

The basic approach is to bend the I sections to form L shapes and arrange them around the magnet in layers. Since the first layer cannot cover the magnet assembly in full, the gaps in this layer will be covered by a second layer. Multiple layers may be used to increase the effectieveness.

Questions:

1) Does CRGO work well as a shield? Any experiences.?

2) If yes, is there any specific form for a shield which can short circuit the field with maximum efficiency.?

3) will this shield work at all. 🙂

PS: the drawing was made in MS word. Sorry for the poor quality.

I've searched the forum and found a mention of CRGO. But couldnt locate any practical Info.

The basic approach is to bend the I sections to form L shapes and arrange them around the magnet in layers. Since the first layer cannot cover the magnet assembly in full, the gaps in this layer will be covered by a second layer. Multiple layers may be used to increase the effectieveness.

Questions:

1) Does CRGO work well as a shield? Any experiences.?

2) If yes, is there any specific form for a shield which can short circuit the field with maximum efficiency.?

3) will this shield work at all. 🙂

PS: the drawing was made in MS word. Sorry for the poor quality.

I've searched the forum and found a mention of CRGO. But couldnt locate any practical Info.

Attachments

There should be no problem with the material. The shield may require a precision of fabrication that would be beyond what I can do in my workshop. You may be much better at metal fabrication than I am.

The words we use to describe phenomena are very important. If you want to read some fascinating work on this please see either Benjamin Lee Whorf or Edward Sapir (both cultural anthropolgists interested in language).

While the word short is appropriate for many activities involving magnetic fields and electricity, here I believe it would be better to think bend or fold.

The typical magnetic shield is a solid piece of metal stamped into the shape of a cup with a smooth (rounded) transitition between the bottom and the sides. This shape bends or folds the magnetic field radiating off the magnet structure and redirects them forward, and out the cone.

Your design will work, but if there are any gaps between the layers of material, or gaps where the I sections are bent, or along the sections around the magnet, then they will radiate the field at that point instead of bending it.

If your fabrication is good, this may provide enough redirection for your application. It is almost certain, however, it will not perform as well as a one piece cup shape shield.

If a one piece shield is not available, then your design may well be the next best option.

Good Luck!

Mark

The words we use to describe phenomena are very important. If you want to read some fascinating work on this please see either Benjamin Lee Whorf or Edward Sapir (both cultural anthropolgists interested in language).

While the word short is appropriate for many activities involving magnetic fields and electricity, here I believe it would be better to think bend or fold.

The typical magnetic shield is a solid piece of metal stamped into the shape of a cup with a smooth (rounded) transitition between the bottom and the sides. This shape bends or folds the magnetic field radiating off the magnet structure and redirects them forward, and out the cone.

Your design will work, but if there are any gaps between the layers of material, or gaps where the I sections are bent, or along the sections around the magnet, then they will radiate the field at that point instead of bending it.

If your fabrication is good, this may provide enough redirection for your application. It is almost certain, however, it will not perform as well as a one piece cup shape shield.

If a one piece shield is not available, then your design may well be the next best option.

Good Luck!

Mark

Actually, this scheme is not a good idea. As shown, the shield will act as a magnetic short between the front and back plate, and divert flux away from the gap. You will therefore lose Bl product and hence sensitivity from the driver.

You should therefore put a reverse polarity bucking magnet on the back plate, then apply your shield concept. However you will need a good thickness of material, otherwise it will saturate and then not work

Andrew

You should therefore put a reverse polarity bucking magnet on the back plate, then apply your shield concept. However you will need a good thickness of material, otherwise it will saturate and then not work

Andrew

Many thanks for those inputs! Further...

The shield may require a precision of fabrication that would be beyond what I can do in my workshop. You may be much better at metal fabrication than I am.

Hi MarkMck,

I was thinking of reusing the Pre-cut "I" sections of CRGO sheets from an old transformer to do this shield. So metal working is restricted to bending the "I" sections which is an easier job, in comparison, i thought. These will be arranged around the magnet to form a cup like structure. There will be some overlap at the centre since the I sections are not cut to triangles. I took to this because i cannot make a cup from sheet metal with my metal working skills. So thought if this works out, would be a generic approach and simpler to implement.

The typical magnetic shield is a solid piece of metal stamped into the shape of a cup with a smooth (rounded) transitition between the bottom and the sides. This shape bends or folds the magnetic field radiating off the magnet structure and redirects them forward, and out the cone.

Sorry, I am not able to visualise that with ease. Is it possible to provide an illustration of the same.?

For I thought, I am trying to do something similar but without a continuous metal structure.

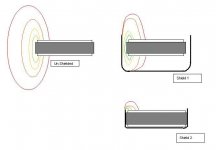

1) To prevent "Shorting" but to enable bending the field, will it work if i leave a space between the magnet and the shield, filled with a low permiability material or air, but still enclosing the magnet?(Pls ref fig.)

AndrewJ...

You should therefore put a reverse polarity bucking magnet on the back plate

I cannot use a bucking magnet for the depth of the speaker increases, which is not acceptable for the specific purpose.

As i said above, if i leave a gap between the magnet and the shield, which is many times broader than the gap will it still affect Bl adversly.?(Pls ref Fig)

The shield may require a precision of fabrication that would be beyond what I can do in my workshop. You may be much better at metal fabrication than I am.

Hi MarkMck,

I was thinking of reusing the Pre-cut "I" sections of CRGO sheets from an old transformer to do this shield. So metal working is restricted to bending the "I" sections which is an easier job, in comparison, i thought. These will be arranged around the magnet to form a cup like structure. There will be some overlap at the centre since the I sections are not cut to triangles. I took to this because i cannot make a cup from sheet metal with my metal working skills. So thought if this works out, would be a generic approach and simpler to implement.

The typical magnetic shield is a solid piece of metal stamped into the shape of a cup with a smooth (rounded) transitition between the bottom and the sides. This shape bends or folds the magnetic field radiating off the magnet structure and redirects them forward, and out the cone.

Sorry, I am not able to visualise that with ease. Is it possible to provide an illustration of the same.?

For I thought, I am trying to do something similar but without a continuous metal structure.

1) To prevent "Shorting" but to enable bending the field, will it work if i leave a space between the magnet and the shield, filled with a low permiability material or air, but still enclosing the magnet?(Pls ref fig.)

AndrewJ...

You should therefore put a reverse polarity bucking magnet on the back plate

I cannot use a bucking magnet for the depth of the speaker increases, which is not acceptable for the specific purpose.

As i said above, if i leave a gap between the magnet and the shield, which is many times broader than the gap will it still affect Bl adversly.?(Pls ref Fig)

Attachments

hi dave.

A bucking magnet is not prefferred for the particular application i'm intending at. I am looking at a low cost easy to make shield but got a little confused regarding the effect it might have on the magnetic circuits of the speaker...!

ajju

A bucking magnet is not prefferred for the particular application i'm intending at. I am looking at a low cost easy to make shield but got a little confused regarding the effect it might have on the magnetic circuits of the speaker...!

ajju

On a recent project I tried something similar though not nearly so involved on the fabrication front. My search for a magnetically conductor ended with some .75 inch by .125 inch soft iron barstock from the local hardware store. I then formed it into a U shape that was designed to mount on the baffle from the back. Then I added two more U shaped pieces to the first so as to make a crude cup to go over the back of the speaker. This setup had a very minimal to no effect on the sound. I must also say that the driver I was trying to shield was about 6in and thus may have a much lower field strength than a larger driver at high volume. The good news was then even this crude shielding had quite a beneficial effect. It completely eliminated the effect on my tv when the speakers were placed beside it, however when the speakers were directly in front of it the magnetic effect distance was halved. While testing the shielding I found a new place for the speakers and ended up not using the bar stock but I had only spent $1.63 on materials. My experience says go ahead and try it, my experaments with the bar about .7inches from the speakers magnet say the sound will likely be uneffected, besides you can always just decide not to use them.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- will this simple shield work..?