The purpose of the window was to allow erasure of the memory using light, UV I believe.Years ago, my co-workers had a strange problem with their prototype. It turned out that they had not covered the window on an EPROM, which was photo sensitive.

Black radiates heat better than colors do. If you want something to expel more heat paint it black. It also absorbs heat but how often do chips see sunlight inside a device?

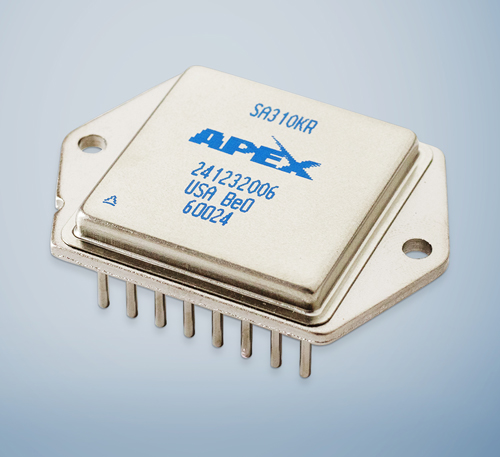

Yes, some are milspec, some are old and some in metal case for heat dissipation.

https://www.digikey.com/en/products/filter/voltage-reference/

https://www.wikiwand.com/en/TO-5

https://www.digikey.com/en/products/filter/voltage-reference/

https://www.wikiwand.com/en/TO-5

My early Guitar/Bass/PA SS amplifiers were built using metallic TO5 , 8 gold plated legs uA741 Op Amps, like the case above.Some IC are in metal case.

I kept using those even after the plastic DIP8 case appeared, reason being I still built them on eyeletted boards 😱

Impossible with tightly spaced DIP8 pins, very doable spreading those long flexible leads like a spider.

Until I learned silkscreening and started making my own PCBs that is.

That is correct.Yes, but after erasure, a special sticker is placed over the window to block light.

Definitely to keep out light - every pn-junction (and Schottky junction?) is a photo-diode, every bipolar transistor is a photo-transistor.Probably to keep out light, which could affect the operation of the semiconductor devices.

The epoxy resin is not inherently black.

With silicon any light from near infra-red up through ultra-violet can affect operation, hence light-proof package. Also every lightly-doped area becomes a photo-resistor too, so you don't need a pn-junction to be affected.

In thin section (a micron or so) silicon is orange in colour due to it preferentially absorbing blue photons. After 10 microns or so its absorbed most light and appears grey/black (but shiny due to the high refractive index). Most semiconductor devices are very thin so light can reach the active areas, unless the chip has a lot of metalization on top.

In the mil-bridge/diode world, back in the day (5 decades or so), two part epoxies were used to encapsulate glass body axial lead diodes for use in 2 and 3 phase bridge assemblies, milspec and commercial. Because the epoxy had an expansion coefficient around 90 ppm/c below glass transition, and 120 above, they would load the epoxy with alumina powder, as much as possible to temper the TCE (down to 28-32 PPM/c). Looking quite horrible, they used carbon black to make it look better.

The HV diode people did NOT like the thought of carbon black as it's (duh) conductive. So they forced (well, tossed money at them) the epoxy vendors to add blue coloring instead of black, as the blue pigment was not conductive. Case closed...or, one would think.

Nowadays, every single high voltage rectifier/stick/encapsulated assembly is made with black epoxy, and the blue epoxy tends to be used for the lower voltage 2 a 3 phase bridges.

Go figure, so much for the "conductive" argument".

I suspect all the IC and transistor encapsulation plastic is a thermoset injection molded. Mixing two part and putting in a mold is not a very good production technique. Mil devices, yes the additional production cost can be recovered. But commercial, nah, injection molded thermoset. With alumina filler of course, there needs to be some semblance of reliability through thermal and power cycling, not to mention surviving a wave (tsunami) of solder..

John

The HV diode people did NOT like the thought of carbon black as it's (duh) conductive. So they forced (well, tossed money at them) the epoxy vendors to add blue coloring instead of black, as the blue pigment was not conductive. Case closed...or, one would think.

Nowadays, every single high voltage rectifier/stick/encapsulated assembly is made with black epoxy, and the blue epoxy tends to be used for the lower voltage 2 a 3 phase bridges.

Go figure, so much for the "conductive" argument".

I suspect all the IC and transistor encapsulation plastic is a thermoset injection molded. Mixing two part and putting in a mold is not a very good production technique. Mil devices, yes the additional production cost can be recovered. But commercial, nah, injection molded thermoset. With alumina filler of course, there needs to be some semblance of reliability through thermal and power cycling, not to mention surviving a wave (tsunami) of solder..

John

- Home

- General Interest

- Everything Else

- why IC body is always black?