So next steps are to remove enough of the ribs to allow a flat plywood board to touch flush with horn wall and that is where bass injection holes will be cut. You can for one board per side for a pyramid cover over horn. Fill in void in between wood and plastic horn wall with hardening industrial adhesive or even automotive finish "Bondo". Make sure it doesn't melt plastic. Even a lot of hot melt glue might work. Epoxy is good.

Since horn has semi rectangular outline you want holes near "corners" as rounded as they are. Wooden boards need a half round circle routed out for rubber surround clearance. Then drill 2 holes ea per driver aimed into corners. It would help to score hole locations with small pilot holes drilled from inside of horn to ensure symmetry and correct location before wood boards glued in place. Stick wooden dowel pins in pilot holes that are long enough to touch flat wooden board. Use ink or dark chalk on dowel tips to show where on wooden boards holes need to go. Drill matching pilot holes on boards. Now use full length dowels to align board while glue sets. Make sure glue doesn't get on dowel (grease it ) so it can be pulled out once glue is hard. Now you have perfect alignment of holes on horn and board and it looks clean. Carefully drill out larger full size hole for bass injection now. Put a piece of backer MDF block or something on the inner horn wall when drilling so it doesn't chip and make huge exit hole from drill plunge. Then carefully use your router/Dremel to enlarge area or volume behind the hole on the board to reduce flow resistance through hole and leading up to a sharp lip or frustrum on inner horn wall. As rule of thumb the two holes should be about 20% of the Sd of driver if you can manage it. Also hole doesn't have to be round. Arc shape crescent moon in my case. Many use "sausage" slots. This helps keep hole profile thinner to reduce impact to waveguide.

Since horn has semi rectangular outline you want holes near "corners" as rounded as they are. Wooden boards need a half round circle routed out for rubber surround clearance. Then drill 2 holes ea per driver aimed into corners. It would help to score hole locations with small pilot holes drilled from inside of horn to ensure symmetry and correct location before wood boards glued in place. Stick wooden dowel pins in pilot holes that are long enough to touch flat wooden board. Use ink or dark chalk on dowel tips to show where on wooden boards holes need to go. Drill matching pilot holes on boards. Now use full length dowels to align board while glue sets. Make sure glue doesn't get on dowel (grease it ) so it can be pulled out once glue is hard. Now you have perfect alignment of holes on horn and board and it looks clean. Carefully drill out larger full size hole for bass injection now. Put a piece of backer MDF block or something on the inner horn wall when drilling so it doesn't chip and make huge exit hole from drill plunge. Then carefully use your router/Dremel to enlarge area or volume behind the hole on the board to reduce flow resistance through hole and leading up to a sharp lip or frustrum on inner horn wall. As rule of thumb the two holes should be about 20% of the Sd of driver if you can manage it. Also hole doesn't have to be round. Arc shape crescent moon in my case. Many use "sausage" slots. This helps keep hole profile thinner to reduce impact to waveguide.

An interesting HF device to try might be the SBAcoustics SB25ATC dome tweeter. Troels recently tested it and it's basically flat line ultra low distortion down to 1khz. With the added boost of the guide once equalized, might make 800hz. Plus the off axis measurements are better than any tweeter I've ever seen.

No such part as SB25ATC

You mean SB25AC-000C-4?

http://www.madisound.com/store/manuals/SB25AC-C000-4.pdf

Problem is getting woofer injection holes to come up to 1k to cross over. Maybe 600Hz doable given how far from throat. So it needs a "tweeter" that can dig deep which why the SB65WBAC25-4 was chosen. Fs is 120Hz I think and 2.5mm xmax.

You mean SB25AC-000C-4?

http://www.madisound.com/store/manuals/SB25AC-C000-4.pdf

Problem is getting woofer injection holes to come up to 1k to cross over. Maybe 600Hz doable given how far from throat. So it needs a "tweeter" that can dig deep which why the SB65WBAC25-4 was chosen. Fs is 120Hz I think and 2.5mm xmax.

Thanks for your words of encouragement guys - lots of Autosol polish used there to get the finish!!

Xrk has kindly offered to move these posts to a new thread of it's own - as my build is taking shape.

Xrk - thanks for the very detailed instructions on getting the injection ports sorted and aligned.

Before I do anything though - I want to take many, many measurements with the SB65, as loud and low as possible to see how low I can cross, how the polar response is with this horn etc.

I will then modify only one horn - that way we can see exactly how the ports effect the response. I may have to buy a few more horns to experiment on! But luckily I can pick them up for about £25 each, so not the end of the world.

What I would like to do is come up with a nice recipe for a smaller, 2-way synergy, that nearly anyone can make with a little DIY skills.

I am also very interested in the recent findings on this forum regarding the smaller full range drivers horn mounted, rather than compression drivers......I have a sneaky feeling they could really bridge the gap between PA application and home application - given that extreme SpLs are not required and the full range drivers may have much lower distortion in this application.

Xrk has kindly offered to move these posts to a new thread of it's own - as my build is taking shape.

Xrk - thanks for the very detailed instructions on getting the injection ports sorted and aligned.

Before I do anything though - I want to take many, many measurements with the SB65, as loud and low as possible to see how low I can cross, how the polar response is with this horn etc.

I will then modify only one horn - that way we can see exactly how the ports effect the response. I may have to buy a few more horns to experiment on! But luckily I can pick them up for about £25 each, so not the end of the world.

What I would like to do is come up with a nice recipe for a smaller, 2-way synergy, that nearly anyone can make with a little DIY skills.

I am also very interested in the recent findings on this forum regarding the smaller full range drivers horn mounted, rather than compression drivers......I have a sneaky feeling they could really bridge the gap between PA application and home application - given that extreme SpLs are not required and the full range drivers may have much lower distortion in this application.

Just a a thought regarding the gaskets which might turn out rather well.

A few speaker builds ago, in some of my final 'ultimate optimizations' I decoupled all the drivers from the front baffle (along with CLD the baffle itself) with 3mm sorbothane sheeting (see thread below):

http://www.diyaudio.com/forums/mult...tor-anyone-spot-any-probs-before-i-start.html

So I have a fair bit of sorbothane sheeting left over - This looks to be the perfect thickness to offset the surrounds of the SB65 - so I will try using this instead of ply/plastic etc.

This may also nicely decouple the SB65 from the horn - potentially reducing distortion further.

A few speaker builds ago, in some of my final 'ultimate optimizations' I decoupled all the drivers from the front baffle (along with CLD the baffle itself) with 3mm sorbothane sheeting (see thread below):

http://www.diyaudio.com/forums/mult...tor-anyone-spot-any-probs-before-i-start.html

So I have a fair bit of sorbothane sheeting left over - This looks to be the perfect thickness to offset the surrounds of the SB65 - so I will try using this instead of ply/plastic etc.

This may also nicely decouple the SB65 from the horn - potentially reducing distortion further.

What I would like to do is come up with a nice recipe for a smaller, 2-way synergy, that nearly anyone can make with a little DIY skills.

🙂

New thread for Bushemeister's bookshelf horn build here:

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

No such part as SB25ATC

You mean SB25AC-000C-4?

http://www.madisound.com/store/manuals/SB25AC-C000-4.pdf

Problem is getting woofer injection holes to come up to 1k to cross over. Maybe 600Hz doable given how far from throat. So it needs a "tweeter" that can dig deep which why the SB65WBAC25-4 was chosen. Fs is 120Hz I think and 2.5mm xmax.

Sorry.....SB26ADC. Measurements are here

troelsgravesen.dk

midwoofer taps can't reach 1khz?

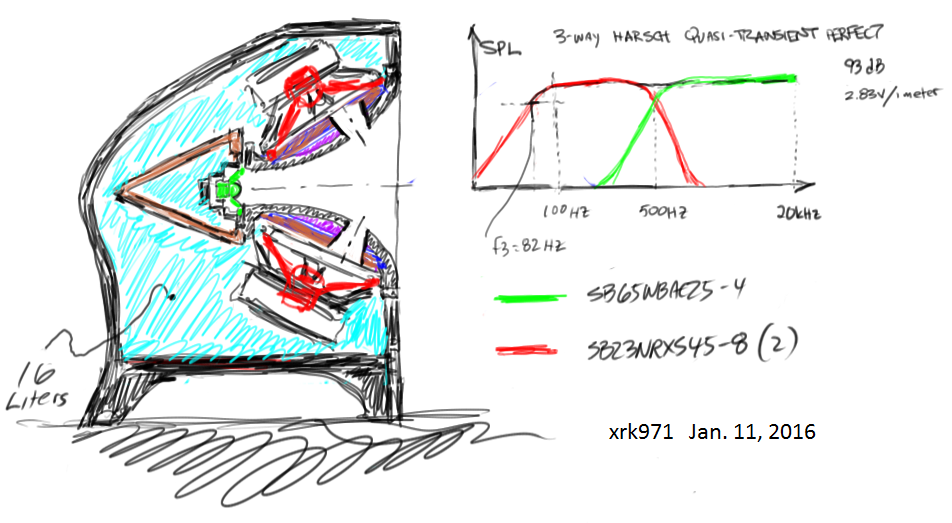

They can on a conventional design with small 2in mids mounted as close to the throat. For the one Bushmeister is making he is looking at using full range 2.5in on the throat to cover 500Hz to 20kHz. Then mids can be bigger 4 of 5in and cover 100Hz to 500Hz. In them conventional design you suggest but with dome tweet the mids would only go down to 400Hz. Then real woofers have to take it below that to 50 or 80Hz. That is fine on a full sale synergy where you have room. We want to cover the 100Hz to 20kHz with 2 drivers. Then pass duties below 100Hz to woofer that doesn't have to go through horn wall injection.

Glad to see this taking shape. I feel that some people have missed the boat not doing this. I know that Tom Danley wanted his people to develope this

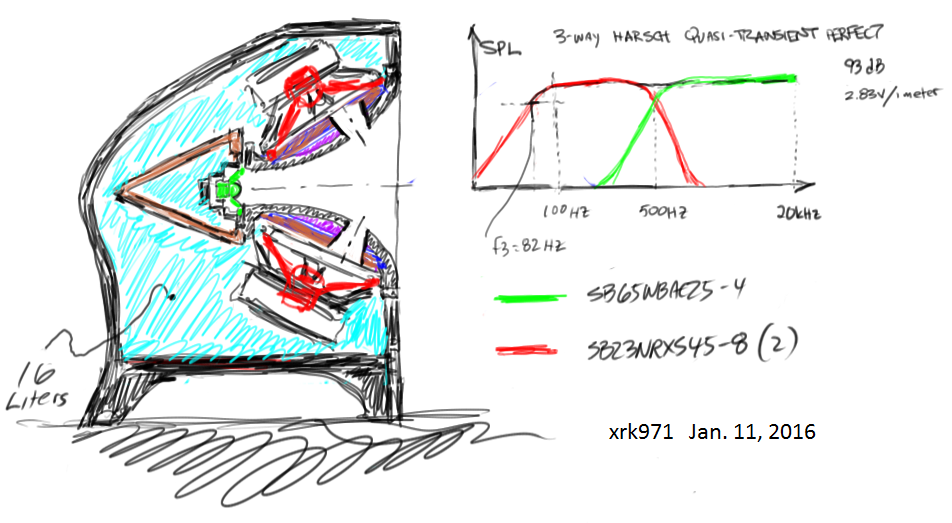

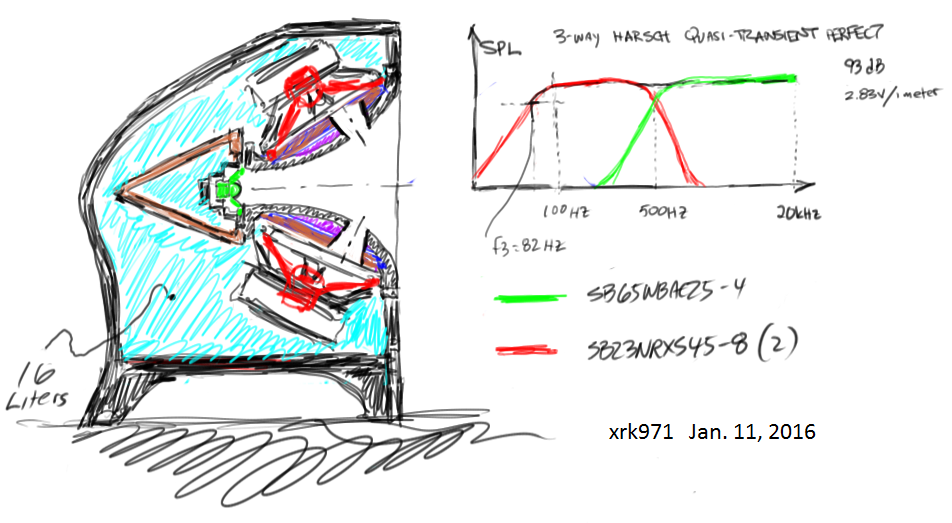

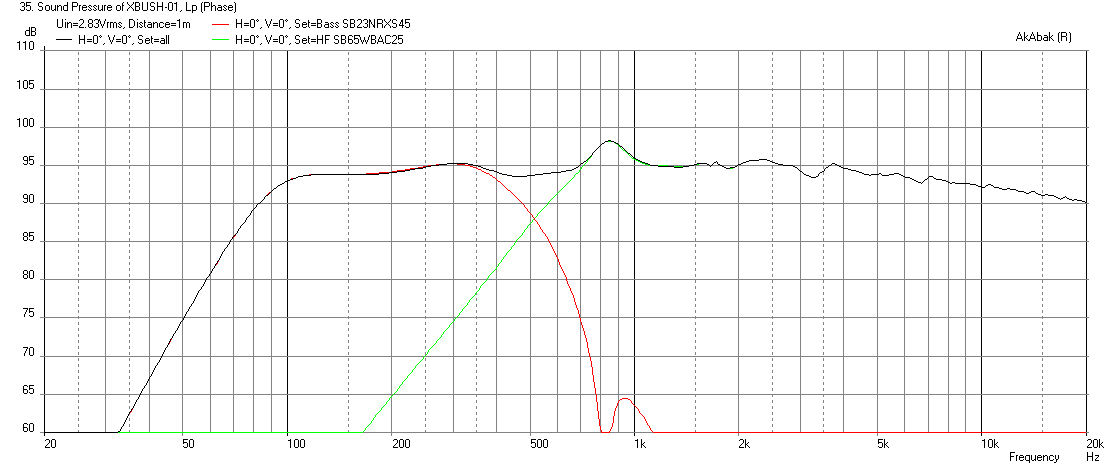

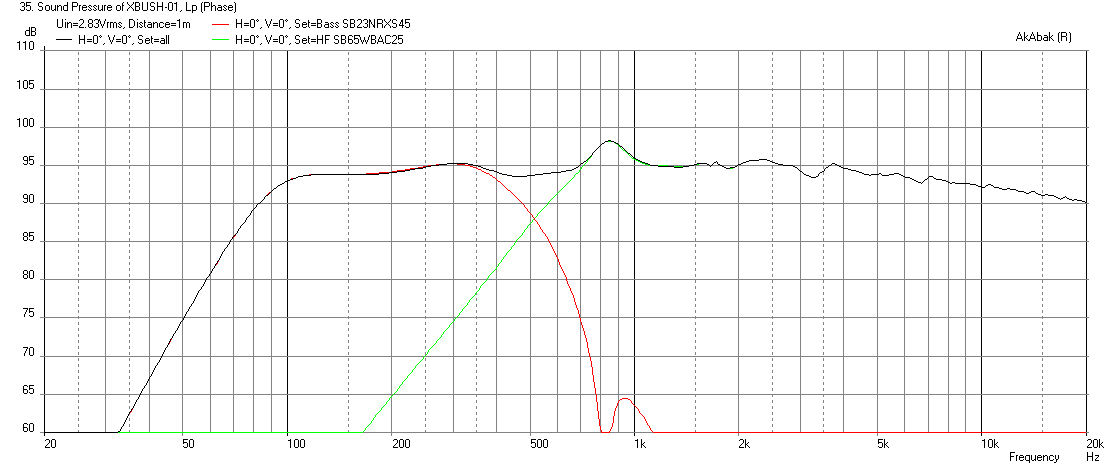

This is the current progression of the design for the bookshelf point source horn:

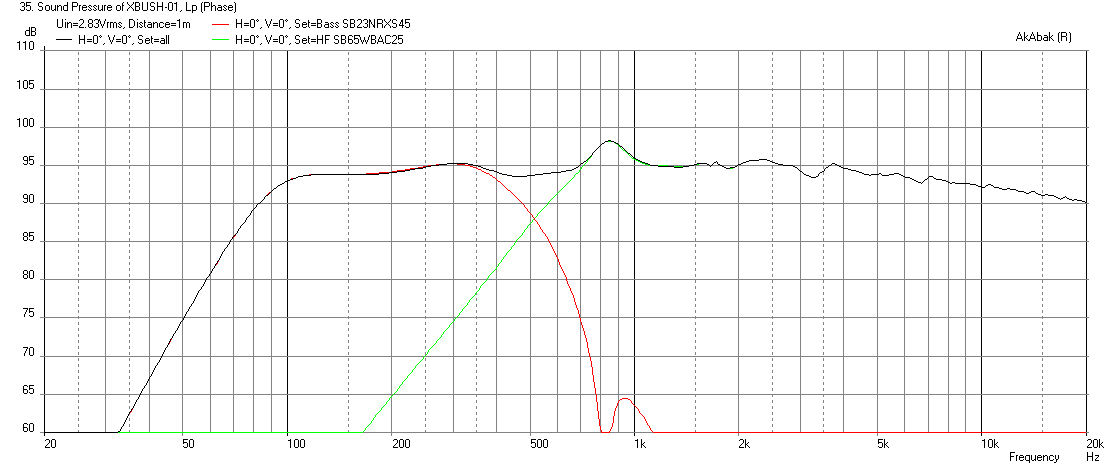

Simulation with SB65WBAC25-4 for mid/tweet and SB23NRXS45-8 (qnty 2) is giving this at 2.83v:

Max predicted SPL based on *thermal* limit of woofers is about 110dB at 22.8v for woofers.

More info here: http://www.diyaudio.com/forums/mult...lti-way-point-source-horn-10.html#post4579092

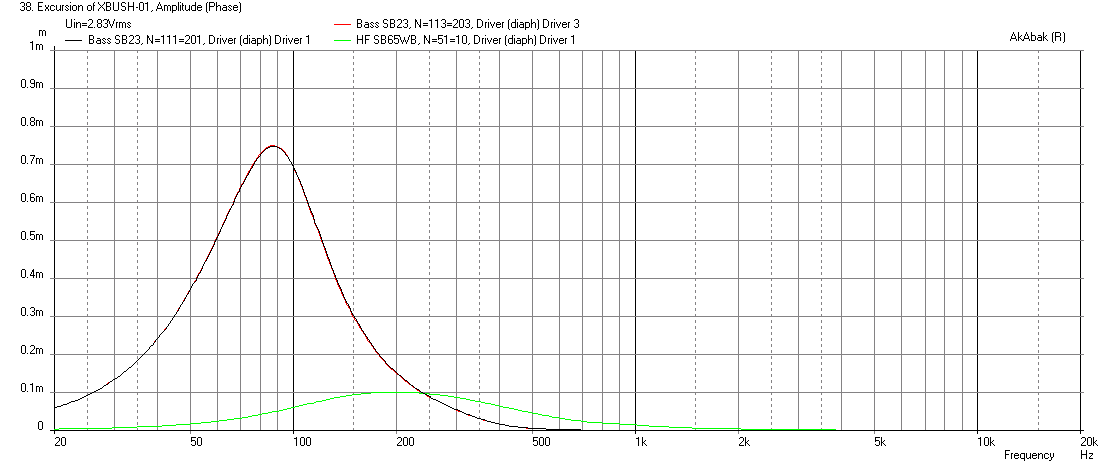

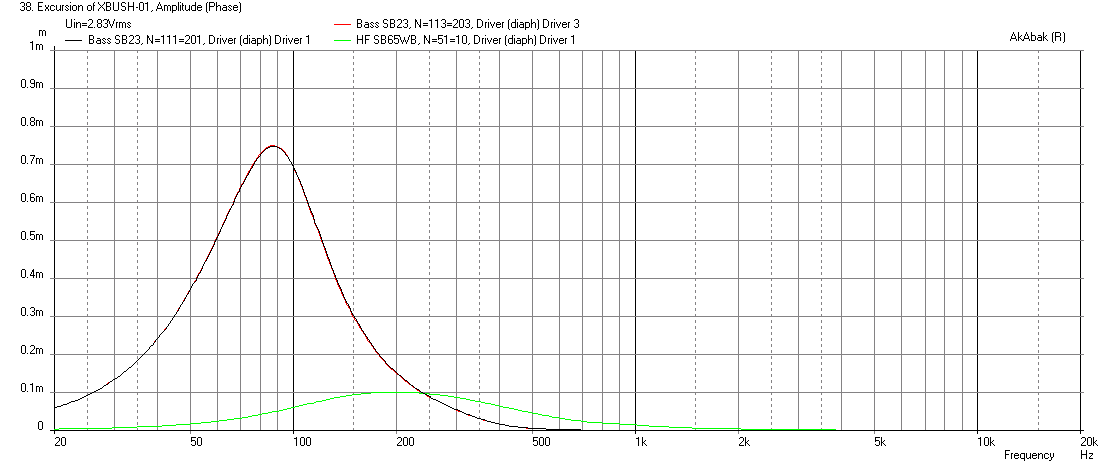

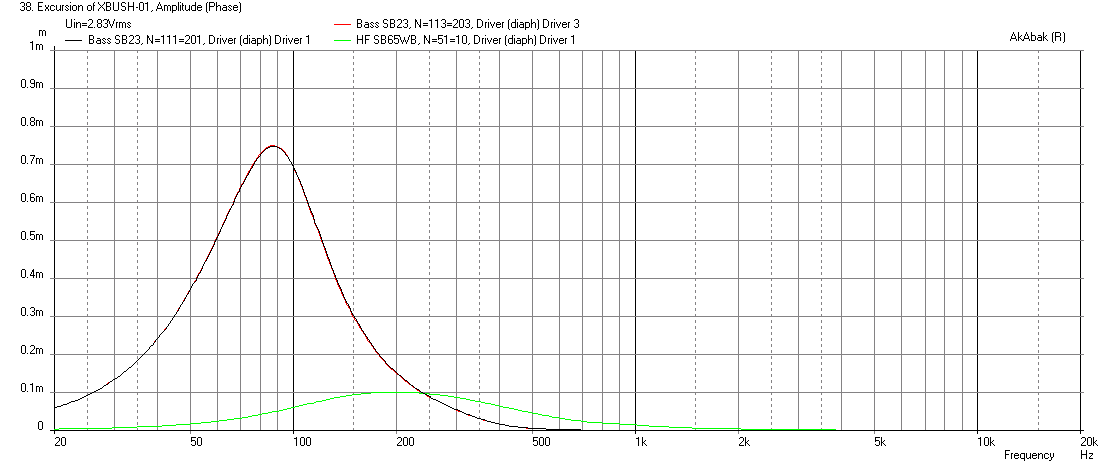

At 2.83v it's at about 93 or 94 dB - pretty loud. But the horn loading is so good, the little 82dB sensitive SB65 is only moving 100 microns on the diaphragm. Given xmax is 2.5mm, this is only a small fraction of linear travel so expect low HD. For the woofer, it is moving only 0.75mm and with 6.25mm xmax, we should also expect low HD as well.

Here is predicted cone motion at 2.83v:

Simulation with SB65WBAC25-4 for mid/tweet and SB23NRXS45-8 (qnty 2) is giving this at 2.83v:

Max predicted SPL based on *thermal* limit of woofers is about 110dB at 22.8v for woofers.

More info here: http://www.diyaudio.com/forums/mult...lti-way-point-source-horn-10.html#post4579092

At 2.83v it's at about 93 or 94 dB - pretty loud. But the horn loading is so good, the little 82dB sensitive SB65 is only moving 100 microns on the diaphragm. Given xmax is 2.5mm, this is only a small fraction of linear travel so expect low HD. For the woofer, it is moving only 0.75mm and with 6.25mm xmax, we should also expect low HD as well.

Here is predicted cone motion at 2.83v:

Last edited:

I'd like to build a "toy" horn. I've read the Danley horn patents and let's just say that I'm not skilled in the art 🙄

I do have on hand several Bose 901-type (CTS) drivers, as well as the inexpensive (< $3 each) drivers ("fool-range" drivers ?) for a sorta- planned line array.

http://www.mcmelectronics.com/product/55-4602

My modeling skills are only in Hornresp and scant at that. Can someone point me to a tutorial to make a simple (not Unity, Synergy, etc.) driver horn? Thanks. And carry on your quality efforts please 🙂

Sent from my NV570P using Tapatalk

I do have on hand several Bose 901-type (CTS) drivers, as well as the inexpensive (< $3 each) drivers ("fool-range" drivers ?) for a sorta- planned line array.

http://www.mcmelectronics.com/product/55-4602

My modeling skills are only in Hornresp and scant at that. Can someone point me to a tutorial to make a simple (not Unity, Synergy, etc.) driver horn? Thanks. And carry on your quality efforts please 🙂

Sent from my NV570P using Tapatalk

Can someone point me to a tutorial to make a simple (not Unity, Synergy, etc.) driver horn? Thanks.

Hmm, soho54's Eazy Horn Excel SS is the only one I'm aware of, then tweak it in HR's Loudspeaker Wizard to 'slide' your way to something that looks acceptable.

GM

Better imaging that 3 pairs of Bose 901s...

Thanks. Looks like ol' reliable Hornresp has been pimped to do synergy type projects too but that is a thicket I have yet to enter 🙂

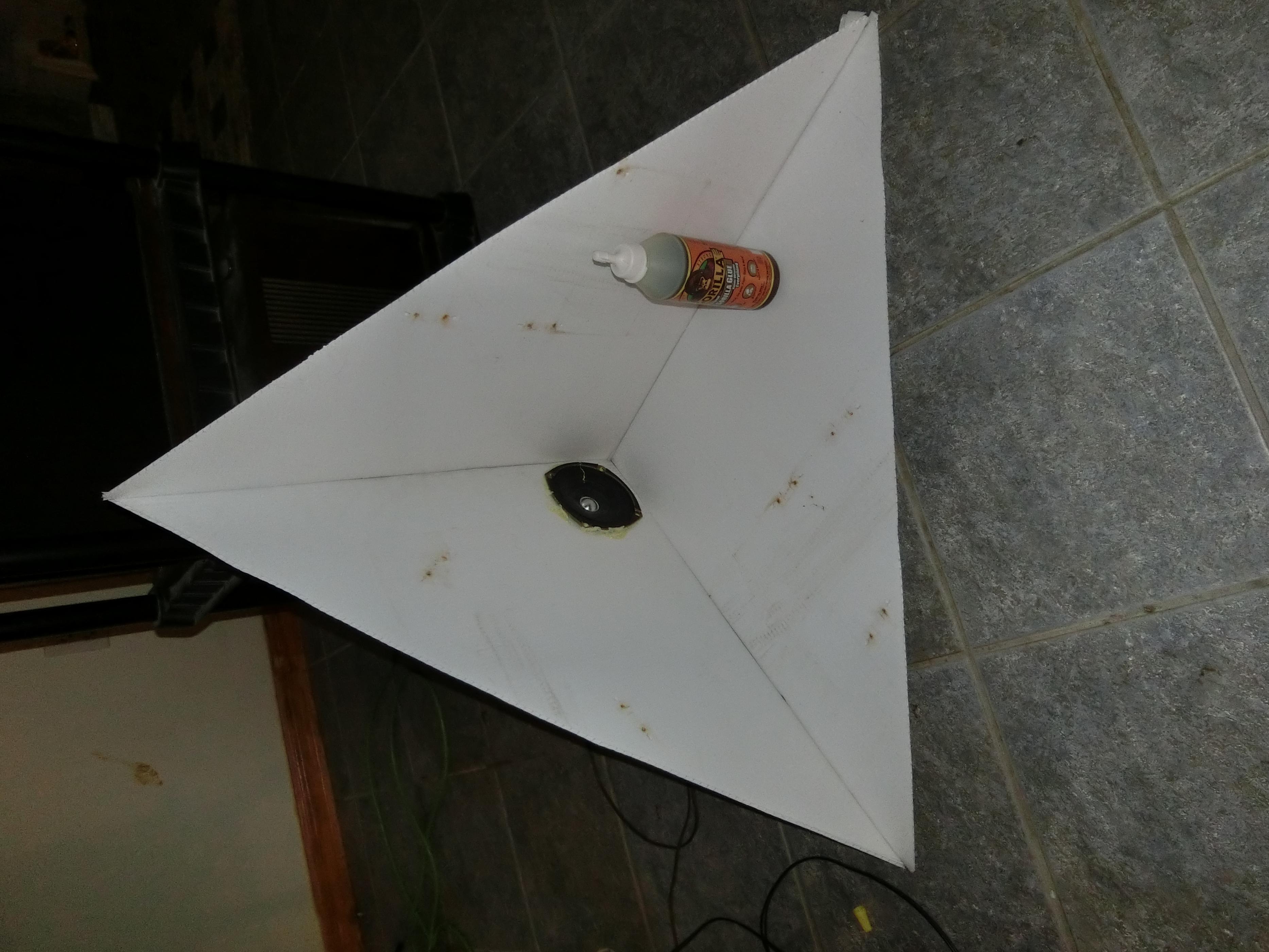

Meanwhile I could not wait for no stinkin' plans so I did my usual prototype with pilfered coroplast (two signs worth), some tape, the two above mentioned $3 drivers and some Gorilla glue. Models like crap on Hornresp, sounds ok. No bass. As installed in the photo I "claim" (darn patent language!) a $6 pair of speakers that is some mongrel of dipole, prism (concial) horn and full range 🙂 A touch of bass is there because (?) floor boundary. More refined product shall have to wait.

Thanks. Looks like ol' reliable Hornresp has been pimped to do synergy type projects too but that is a thicket I have yet to enter 🙂

Meanwhile I could not wait for no stinkin' plans so I did my usual prototype with pilfered coroplast (two signs worth), some tape, the two above mentioned $3 drivers and some Gorilla glue. Models like crap on Hornresp, sounds ok. No bass. As installed in the photo I "claim" (darn patent language!) a $6 pair of speakers that is some mongrel of dipole, prism (concial) horn and full range 🙂 A touch of bass is there because (?) floor boundary. More refined product shall have to wait.

Attachments

I'd like to build a "toy" horn. I've read the Danley horn patents and let's just say that I'm not skilled in the art 🙄

I do have on hand several Bose 901-type (CTS) drivers, as well as the inexpensive (< $3 each) drivers ("fool-range" drivers ?) for a sorta- planned line array.

4.5 Inch 10W 8 Ohm Full Range Pincushion Speaker | XF-119-208 (XF119208) | Distributed By MCM

My modeling skills are only in Hornresp and scant at that. Can someone point me to a tutorial to make a simple (not Unity, Synergy, etc.) driver horn? Thanks. And carry on your quality efforts please 🙂

Sent from my NV570P using Tapatalk

See the SynergyCalc spreadsheet and pdf detailed instruction files in my signature, if you haven't already....

In post 27 asked why not use mids without ports? I understand the design goals. STill has flush mids been tried? Yes you lose the desired (?) LPF but potentially can go much Hertzer in frequency 🙂

Sent from my SPH-L300 using Tapatalk

Sent from my SPH-L300 using Tapatalk

Thanks. Looks like ol' reliable Hornresp has been pimped to do synergy type projects too but that is a thicket I have yet to enter 🙂

Meanwhile I could not wait for no stinkin' plans so I did my usual prototype with pilfered coroplast (two signs worth), some tape, the two above mentioned $3 drivers and some Gorilla glue. Models like crap on Hornresp, sounds ok. No bass. As installed in the photo I "claim" (darn patent language!) a $6 pair of speakers that is some mongrel of dipole, prism (concial) horn and full range 🙂 A touch of bass is there because (?) floor boundary. More refined product shall have to wait.

Here's your waveguide :

I'm using the same full-range driver in a SAW lens like this:

It would be trivial to 'scale up' the SAW lens and add midbasses it to it. So you'd have the full-range response of XRK971's horn, but in a form factor that can be pushed absolutely all the way into a corner. I went that route because I wanted to push the waveguide all the way into the corner of my car's dash:

BTW, I may have mentioned this option before, in this thread. If I have, my apologies! I have too many projects going at the same time.

This is the current progression of the design for the bookshelf point source horn:

Simulation with SB65WBAC25-4 for mid/tweet and SB23NRXS45-8 (qnty 2) is giving this at 2.83v:

Max predicted SPL based on *thermal* limit of woofers is about 110dB at 22.8v for woofers.

More info here: http://www.diyaudio.com/forums/mult...lti-way-point-source-horn-10.html#post4579092

At 2.83v it's at about 93 or 94 dB - pretty loud. But the horn loading is so good, the little 82dB sensitive SB65 is only moving 100 microns on the diaphragm. Given xmax is 2.5mm, this is only a small fraction of linear travel so expect low HD. For the woofer, it is moving only 0.75mm and with 6.25mm xmax, we should also expect low HD as well.

Here is predicted cone motion at 2.83v:

Your horn is a perfect candidate for 3D printing!!!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Why aren't we building bookshelf Synergy monitors?