I don't see a "better" sub-forum for this, so feel free to tow this thread if it is better-off elsewhere. People build electrostatics in the Exotic forum, but that seems a bit different.

Has anyone messed around with building their own electrodynamic drivers? I will never forget a demo a professor did in freshman Physics II (E&M). He glued a ceramic ring magnet to a plastic coffee can lid, cut a hole in the lid in the ring's center, held a nail coiled with enameled wire in the hole and hooked it up to a cheap FM radio. I didn't care how crappy it sounded...it was just plain cool. Audio wasn't something that I got into until a good 5 years later, and it has been almost 5 more years since then.

I have been thinking about that demo, and it seems like it would be a lot of fun to repeat that simple proof-of-concept. I know that I'd not be making anything I would actually use for listening purposes, but tinkering is too much fun. Now, I know of at least one individual on here that designs and sells their own high quality drivers (he also provides some damn good free plans). How did folks that got into designing their own drivers, GET into designing them? "Lots of experience" seems like a reasonable guess. Does anyone have DIY ED driver projects to post up? I don't care if it is a beautiful driver with a carefully designed, cast aluminum frame, or a coffee can lid with a 'fridge magnet; it would be fun to see pictures of trial & error attempts and funky prototype stuff.

When I get around to it, I'll see about posting up whatever I concoct. Maybe I will even hit it with HOLMImpulse & my ECM8000 for kicks. I think I may accidentally burn off the enamel on the wire before I get that far, though!

Has anyone messed around with building their own electrodynamic drivers? I will never forget a demo a professor did in freshman Physics II (E&M). He glued a ceramic ring magnet to a plastic coffee can lid, cut a hole in the lid in the ring's center, held a nail coiled with enameled wire in the hole and hooked it up to a cheap FM radio. I didn't care how crappy it sounded...it was just plain cool. Audio wasn't something that I got into until a good 5 years later, and it has been almost 5 more years since then.

I have been thinking about that demo, and it seems like it would be a lot of fun to repeat that simple proof-of-concept. I know that I'd not be making anything I would actually use for listening purposes, but tinkering is too much fun. Now, I know of at least one individual on here that designs and sells their own high quality drivers (he also provides some damn good free plans). How did folks that got into designing their own drivers, GET into designing them? "Lots of experience" seems like a reasonable guess. Does anyone have DIY ED driver projects to post up? I don't care if it is a beautiful driver with a carefully designed, cast aluminum frame, or a coffee can lid with a 'fridge magnet; it would be fun to see pictures of trial & error attempts and funky prototype stuff.

When I get around to it, I'll see about posting up whatever I concoct. Maybe I will even hit it with HOLMImpulse & my ECM8000 for kicks. I think I may accidentally burn off the enamel on the wire before I get that far, though!

Last edited:

Has anyone messed around with building their own electrodynamic drivers?

Look for posts by Vikash, specifically one that may have the terms diy dynamic driver in it. I posted a spreadsheet you might find interesting.

I am considering doing this myself. I have two cast/milled aluminium 10" basket assemblies with huge magnets from car subwoofers... 2" voice coil gap. I'm thinking it could be fun to try to make them into 3" or 4" diaphragm compression drivers for midbass/mid. There's loads of room inside the basket to put a short horn+phase plug. 😀

Last edited:

Cool, found it.

http://www.diyaudio.com/forums/multi-way/17936-diy-dynamic-driver.html

Hopefully I will eventually do a little better than a plastic lid since I have pretty good access to a lathe & mill. I like the idea of taking a bunch of flat Neodymium magnets & arranging them in a circle. A local electronic surplus place has a huge assortment of Neodymium magnets of all sorts of sizes.

http://www.diyaudio.com/forums/multi-way/17936-diy-dynamic-driver.html

Hopefully I will eventually do a little better than a plastic lid since I have pretty good access to a lathe & mill. I like the idea of taking a bunch of flat Neodymium magnets & arranging them in a circle. A local electronic surplus place has a huge assortment of Neodymium magnets of all sorts of sizes.

Many diyAudio members build their own drivers. Some are the best in the world (look at AE speakers John_E_Janowitz f. example). You can also look at Markaudio,Who Has Built Their Own Drivers?

http://www.diyaudio.com/forums/markaudio/

This type of thread tend to be very short unless the OP is actually building something.

anyone into DIY speaker driver building

http://electronics.howstuffworks.com/speaker5.htm

Last edited:

Member

Joined 2003

A couple of DIY AMT motors using the AC 30130 diaphragm.

Oh wow, those are pretty nice.

I could teach you to assemble (glue together) a driver in half an hour. The challenge is having all the parts. If we are talking woofer design then having the variety of parts to get to the final parameters you want takes a huge variety of samples (woofer design still includes a lot of trial and error). Plus the parts are only compatible if the voice coil diameter (exact diameter, not nominal) is right for the magnet structure and the cone neck ID. For that reason most companies building samples will include coil winding and machining magnet structure parts (e.g. top plate ID) in the process.

If you are talking about building from scratch, then electrostatic units look like a challenging but doable project.

David S.

If you are talking about building from scratch, then electrostatic units look like a challenging but doable project.

David S.

UTS Ultra-Thin Speakers - Warwick Audio Tech

New discoveries and technologies no one knows about.😎

TRENDBIRD (What's Next Big Thing ?) :: Ultra-Thin Speakers - Warwick Audio Tech pic

BBC NEWS | Technology | Thin speaker offers 'crisp sound'

The Technology | warwickaudiotech.com

FFL, Flat Flexible Loudspeaker, Warwick Audio Technologies, Warwick University

New discoveries and technologies no one knows about.😎

Revolutionary speaker in line for innovation prize Education 24dash.comThe new 'Flat, Flexible Loudspeaker' uses a bendy laminate made up of thin, conducting and insulating materials, which when vibrated by an electrical signal produces a clearer, crisper noise.

The FFL was first developed by Dr Duncan Billson and Professor David Hutchins, both from the University of Warwick, with early trials using just two sheets of tinfoil and an insulating layer of baking paper to produce sound.

Sounds good: The flat loudspeaker that is as thin as a sheet of foil | Mail Online

TRENDBIRD (What's Next Big Thing ?) :: Ultra-Thin Speakers - Warwick Audio Tech pic

BBC NEWS | Technology | Thin speaker offers 'crisp sound'

British engineers at a spin-off company of Warwick University have made a groundbreaking new loudspeaker that is only 0.25mm thick, looks like tin foil and cn be printed on/used as a wall poster.

Loudspeaker that's as thin as a sheet of foil // Current TV

The Technology | warwickaudiotech.com

FFL, Flat Flexible Loudspeaker, Warwick Audio Technologies, Warwick University

Attachments

Last edited:

Sounds a bit like the Pioneer HPM (High Polymer Membrane, I think) of some years back. Turning your wall into a speaker seldom sounds good, but my wife got a greeting card that had the inside driven by some sort of element (probably piezo). It actually sounded decent.

David S.

David S.

I did something similar in highschool physics. I wound a voicecoil out of copper wire around a paper towel tube. I wrapped many layers and eventually put the coil in the center of a pair of ring magnets. Before I did that, though, I connected the coil to an old receiver and held a very small neodymium magnet near the coil. It was enough to make music and was one of the coolest things ive done.

By Peter Larsen, LOUDSOFT:

Woofer Design using BLx curve - FINEMotor 2008

http://www.loudsoft.com/loudsoft/my files/Articles/Woofer Design using BLx curves.pdf

6 inch Woofer Design - VOICE COIL article 1, 2006

http://www.loudsoft.com/loudsoft/my files/Articles/6 inch Woofer Design_VOICECOIL_1.pdf

more:

Articles / Papers

http://www.loudsoft.com/default.asp?site=Home - produkts

Woofer Design using BLx curve - FINEMotor 2008

http://www.loudsoft.com/loudsoft/my files/Articles/Woofer Design using BLx curves.pdf

6 inch Woofer Design - VOICE COIL article 1, 2006

http://www.loudsoft.com/loudsoft/my files/Articles/6 inch Woofer Design_VOICECOIL_1.pdf

more:

Articles / Papers

http://www.loudsoft.com/default.asp?site=Home - produkts

Last edited:

Here a video inside of Focal with details of typical “W” composite sandwich cone being made and cut with the help of LASER.

Focal Professional studio monitor loudspeakers, for recording, mastering and home studios

Focal Professional studio monitor loudspeakers, for recording, mastering and home studios

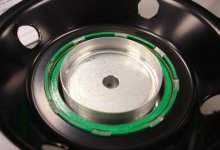

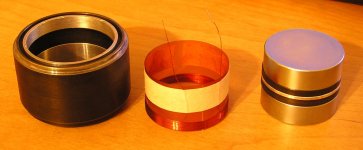

I was working on some of my own drivers several years ago. I attached some pics. I keep moving though and it slows me down.

Speaker dave is right - it is pretty easy to assemble a driver. I helped build thousands at my last job and after you do a couple it is pretty easy. It's having the parts. If you don't have a pile of parts you want to use, then you have to do all the design work from scratch which takes a long time if you are trying to hit a particular set of parameters. Then if you're doing it all yourself, designing the tooling is potentially just as long a process if you haven't done something just like it before.

Speaker dave is right - it is pretty easy to assemble a driver. I helped build thousands at my last job and after you do a couple it is pretty easy. It's having the parts. If you don't have a pile of parts you want to use, then you have to do all the design work from scratch which takes a long time if you are trying to hit a particular set of parameters. Then if you're doing it all yourself, designing the tooling is potentially just as long a process if you haven't done something just like it before.

Attachments

Hi David,

They are center neo magnet structures. In some of them (like the 5th and 6th pictures), I have an additional top neo magnet with the opposite magnetic polarity. It's supposed to increase the flux in the gap, and it also changes the shape of the flux field. However if you design it wrong, the top magnet will repel and potentially violently remove itself from the speaker after you think you have it nicely glued in place.

They are center neo magnet structures. In some of them (like the 5th and 6th pictures), I have an additional top neo magnet with the opposite magnetic polarity. It's supposed to increase the flux in the gap, and it also changes the shape of the flux field. However if you design it wrong, the top magnet will repel and potentially violently remove itself from the speaker after you think you have it nicely glued in place.

A couple of DIY AMT motors using the AC 30130 diaphragm.

Hey Paul ! Was checking out the Octagon.I was waiting to see Bruce Lee on the 120" screen ! 😀

Beautiful Job ! A real labor of love.😉 You left out a few details.

Some Assorted System Stats… Cost of room ?? I was wondering how much something like that would set me back if i were to undertake a project like that. Thanks !

If you don't want to say that's fine I know it had to be Big Bucks though.Looks to be about a $50K room or more

Member

Joined 2003

Hi Altec,

There are some system stats at the end of the Octagon web page...just ask if there is anything else you want to know.

Audio (and finding decent inexpensive wines) are my only current vices so I didn't keep track of cost. DIY helped immensely 😉

There are some system stats at the end of the Octagon web page...just ask if there is anything else you want to know.

Audio (and finding decent inexpensive wines) are my only current vices so I didn't keep track of cost. DIY helped immensely 😉

A couple of DIY AMT motors using the AC 30130 diaphragm.

Yours look a bit more professional than mine:

HERE

Still I'm listening to them now, the biggest challenge with AMTs was making the diaphragm.

My next challenge is to build something approaching midbass drivers, as I want to say i completely built a set of speakers.

I'm not bothered if they are world class, I just want to do it all from scratch, will probably go field-coil for the fun of it and I havent worked out how to manufacture a basket yet.

Nick

Member

Joined 2003

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Who Has Built Their Own Drivers?