Bob, it is obvious you have never tried hardwiring or you would not make such foolish statements about tweaks & snake oil, you don't have a right to speak out so definitively on the subject until you have gotten your hands dirty with experimenting with it. I'm not selling anything other than sharing what I have experienced by experimentation & hearing the results with conformation for others as to my findings so I wasn't just "Holding onto the Faith". This is a major change or upgrade we are talking of here not just a "I think it's different? Right?" as your secretly trying to justify all the money you just spent on a .000003758% increase in audio quality. Now give the Devil his due, hardwiring is not as convent for disassembly or kids running by but if you will try it your thoughts my turn to "How do I keep the kids/grandkids away from this or where is a safe place for my Baby?" Hahaha...

Last edited:

How do you like your access to the inside of the speaker cab? Terminal cup makes sense when the cab is permanently sealed to provide some access to wiring and internals. If the entire back simply screws down, then that's your terminal cup.

For speaker wires I was told fresh OFC crimped into a gold plated connector was better and would last longer.... It certainly looks better than simple cables screwed down into the binding posts.... I can't say I noticed a difference in audio quality.

I guess I'd say properly crimped or properly soldered is better than bare corroding wires or screw down plugs....

For speaker wires I was told fresh OFC crimped into a gold plated connector was better and would last longer.... It certainly looks better than simple cables screwed down into the binding posts.... I can't say I noticed a difference in audio quality.

I guess I'd say properly crimped or properly soldered is better than bare corroding wires or screw down plugs....

Can you point us towards were we can get these?

Couple of examples:

https://www.parts-express.com/parts-express-banana-5-way-speaker-wire-binding-post-terminal--260-301

https://www.parts-express.com/round-speaker-terminal-cup-2-15-16-gold-banana-binding-post--260-283

What is the most effective way to prevent oxidization of the bare speaker cable end? How about cover it with thin solder?

At the very least, a tight twisting and tinning with solder can eliminate the danger of loose strands shorting out in tight spacing a when using only "bare wire"

If we want to talk snake oil, how about the audibly distinguishable merits of the various alloy percentages, flux chemistries, and soldering temperatures. Personally I've found the earlier formulation of Cardas Quad Eutectic to be a dream to work with, as was the original "Wonder Solder" - but sound better?

ABTN - some of here have survived over 50yrs of kool-aid, snake oil, and the latest "revolutionary discoveries" to earn the right I think, as Bob did, to call out the BS portion of any scribblings here. Post long enough, and you might make the same judgement of some of your own earlier posts - I know I have certainly changed my view on a few things.

We all have the right to convince ourselves that we hear a difference -very possible, perhaps even easily measured, and /or improvement. Trickier, that last one is.

If we want to talk snake oil, how about the audibly distinguishable merits of the various alloy percentages, flux chemistries, and soldering temperatures. Personally I've found the earlier formulation of Cardas Quad Eutectic to be a dream to work with, as was the original "Wonder Solder" - but sound better?

ABTN - some of here have survived over 50yrs of kool-aid, snake oil, and the latest "revolutionary discoveries" to earn the right I think, as Bob did, to call out the BS portion of any scribblings here. Post long enough, and you might make the same judgement of some of your own earlier posts - I know I have certainly changed my view on a few things.

We all have the right to convince ourselves that we hear a difference -very possible, perhaps even easily measured, and /or improvement. Trickier, that last one is.

....you don't have a right to speak out so definitively on the subject until you have gotten your hands dirty with experimenting with it..

I have been building speakers and associated audio equipment for 50 years. I suspect from your avatar, you have not. I have gotten my hands dirty. Hard wiring everything can make a minor audible difference, but your excursion into hyperbole it totally unjustified. I've been there, done that. Just passing on my experience.

Bob

With Bob. No surprises there.

OK, to a point I'd agree there is something in it, inasmuch as connections have caused more grief in electronics (any) over the years than wire ever has. The Speakon connections are about as good as it gets for speaker level, with proper eye lugs, either cold-welded onto the wire or wire-wrap, compression fastened and coated with copper-grease being about the only thing that can beat them on a technical level. For there to be any real advantage in hardwiring generally requires HE systems -i.e. in the 100dB 1m/W category. Below that, the losses tend to get swamped out by other issues. That said, I'd generally avoid big lumps of brass-plated base metals unless you need it for ruggedness, since they're a pain to work with and there's no advantage to them, unless you go for the bling factor, which is a bit daft when you consider we're talking about speaker connections. 😉

OK, to a point I'd agree there is something in it, inasmuch as connections have caused more grief in electronics (any) over the years than wire ever has. The Speakon connections are about as good as it gets for speaker level, with proper eye lugs, either cold-welded onto the wire or wire-wrap, compression fastened and coated with copper-grease being about the only thing that can beat them on a technical level. For there to be any real advantage in hardwiring generally requires HE systems -i.e. in the 100dB 1m/W category. Below that, the losses tend to get swamped out by other issues. That said, I'd generally avoid big lumps of brass-plated base metals unless you need it for ruggedness, since they're a pain to work with and there's no advantage to them, unless you go for the bling factor, which is a bit daft when you consider we're talking about speaker connections. 😉

TIf there is a crossover move it out of the box also. This will give you a major component upgrade like no other that's so easy to do.

I think you may need to relook at what you used for wire? Lousy wire, poor dielectric, long runs, will cause the same effect as lousy fittings & remember to use good stuff inside of your equipment also. I'm 51, been playing with this stuff for most my life & the picture is a couple of yrs old & of me then same as now, maybe naive in my outlook at the world & thinking everyone is looking for the best sound & not locked into an ideal? I can't believe you didn't see a major difference, something was wrong in how you went about it. I don't understand Bob, after looking at your site & if you are a minimalist you should be all over this lack of metal thing for yourself, not for a sales market of course.

Last edited:

The 1st is good. Simple, but does not recess the terminals. I have a few sets of those kicking around for when the need arrises, The 2nd is the right cup but uses the solid metal posts. They would be better with the plastic shanked posts in the 1st link.

That combo is what we use, but so far i have had to buy at least 100 units to get them, so they may only be available at retail from me (and i don’t actively sell them, you have to ask). And surprisingly, less expensive than the 2nd one above.

dave

You need to provide your criteria for what constitutes 'lousy wire', 'poor dielectric' and 'long runs'.

Alas, that is also not always the case. Most multiway speakers I have designed use external crossovers during the prototyping stage for reasons that are fairly obvious. I have yet to encounter any degradation in performance when they are placed within the enclosure. That said, I avoid electrolytics which can (as in 'can', not 'automatically do') suffer from microphonic issues, and ensure that the boards are properly mounted and isolated when it is necessary for them to be so. I've tried direct comparisons of this a number of times with otherwise identical pairs of speakers. No difference, either measurable, or audible. That does not mean there can't be, just that claiming it will invariably occur is nonsense. Incidentally, telling people they should rip out the internal wiring and replace it with something else also has some potential issues. I have encountered speakers on a number of occasions where the electrical characteristics of the internal wiring formed a functional part of the design, and making changes will negate this. It doesn't often happen, but it sometimes crops up, so you have to keep an eye out for these things. Sorry to upset you, but sweeping generalisations presented as fact do nobody any favours.

If there is a crossover move it out of the box also. This will give you a major component upgrade like no other that's so easy to do

Alas, that is also not always the case. Most multiway speakers I have designed use external crossovers during the prototyping stage for reasons that are fairly obvious. I have yet to encounter any degradation in performance when they are placed within the enclosure. That said, I avoid electrolytics which can (as in 'can', not 'automatically do') suffer from microphonic issues, and ensure that the boards are properly mounted and isolated when it is necessary for them to be so. I've tried direct comparisons of this a number of times with otherwise identical pairs of speakers. No difference, either measurable, or audible. That does not mean there can't be, just that claiming it will invariably occur is nonsense. Incidentally, telling people they should rip out the internal wiring and replace it with something else also has some potential issues. I have encountered speakers on a number of occasions where the electrical characteristics of the internal wiring formed a functional part of the design, and making changes will negate this. It doesn't often happen, but it sometimes crops up, so you have to keep an eye out for these things. Sorry to upset you, but sweeping generalisations presented as fact do nobody any favours.

Last edited:

Boards ?and ensure that the boards are properly mounted and isolated when it is necessary for them to be so

Oh, boy !

Hard wired on wood, PCB or alternatives. Depends on the speaker & its requirements / goals. Name your poison: 😉 https://www.youtube.com/watch?v=EZ9se8i4ujs

What's wrong with solid metal posts? I read somewhere that electrons flow on the outside of a conductor (never witnessed it myself) so...? Wire wrapping is one of those things I swore to never do again but makes a great connection I'd agree. Any particular speakon recommended?

Not a lot in most cases, providing they're low resistance and you can get a decent contact. Some of the big beasts are made of relatively high resistance base metals though & in HE systems the connection losses can be audible. For most uses though, the main issue is that you're spending money on them that would probably be better spent elsewhere.

Re the Speakon connections, they're all good, so nothing major AFAIK to worry about there.

Re the Speakon connections, they're all good, so nothing major AFAIK to worry about there.

What's wrong with solid metal posts?

I want as little metal as possible between my amp & speakers.

dave

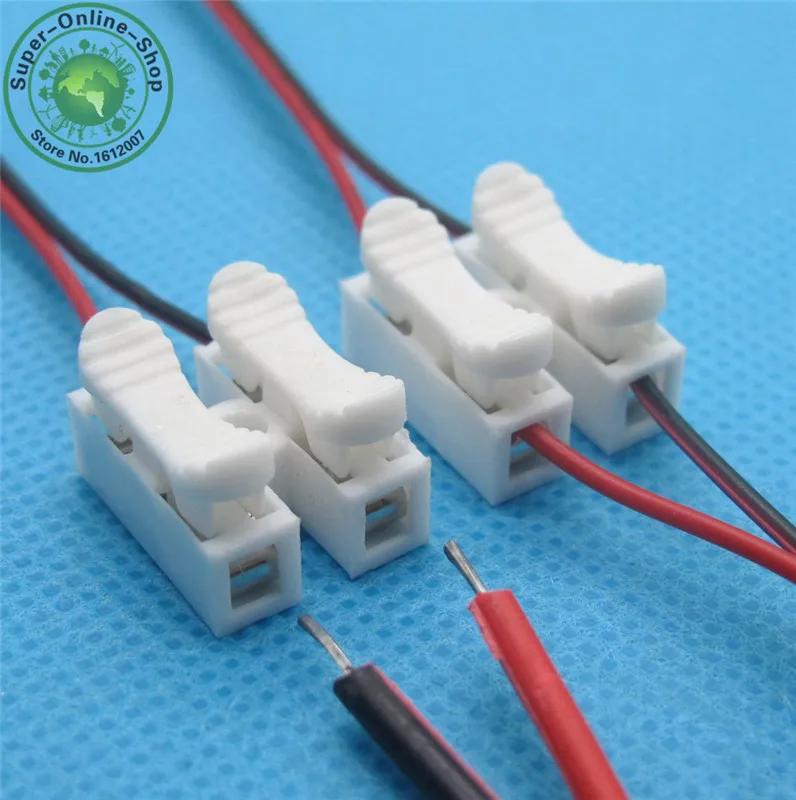

So I can see how bare wire hanging out of the back of the cabinet is probably a no go for commercial speakers, but for a DIY-er like me, it could be just the thing. The three sets of cabs I'm making will be re-positioned many times, so I can't go bare wire right to the amp (i.e. the distance to the amp will change a few times over the lifetime of the cabs). So how about using some kind of terminal block/connector to securely connect the cabinet wire to whatever length is needed to get to the amp? Maybe there's something like this avail. but with just two connections..?

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- What's best: stand-alone binding posts or terminal cups?