What about a math co-processor? Auto desk AutoCad was big on systems to run their software needing them. i387, could have been a 386 that didn't quite meet all the specs. That was the rumor.I keep one specifically for those old but essential programs - Needhams device burner and most specifically Protel Autotrax, which has 25 years of PCB designs and libraries - because of my fundamental distrust of mechanical hard drives, I use a CF card with an IDE converter as the HD.

But it hurt to have to buy a 5 pack of resistors at RatShack for the cost of 50 when mail ordered. The "kids" working there seemed to think I must have been a mad scientist. All they knew anything about was cell phones, monthly plans, and ink cartridges. Not surprising they tanked. Competition in the mobile phone retail industry is intense, with little room for the faint at heart to wiggle around in.only thing i hate about do it yourself is waiting for parts ordered miss the days of buying local

I need a warehouse, with those shelves like they have in museums. They turn the crank until the correct shelf set opens up.

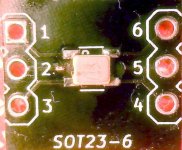

I hate dealing with components sized for smart-phone integration. I have to put them on something bigger, for my fumble fingers to grip and place -

Soldering the heater wires onto octal tube sockets is more my speed ;')

Soldering the heater wires onto octal tube sockets is more my speed ;')

Attachments

I've fumbled with stuff smaller than that, using something to support the hands is a must. As long as you have a good microscope and thin enough soldering tip and tin it's all good.

What I hate about DIY audio is that it looks like I will have to shelve it completely for the foreseeable future due, to time and money needed for home restoration to reduce our energy footprint to a high enough degree that we can reduce our bills... It is a complex task and an even more complex piece of advanced mathematics.

What I hate about DIY audio is that it looks like I will have to shelve it completely for the foreseeable future due, to time and money needed for home restoration to reduce our energy footprint to a high enough degree that we can reduce our bills... It is a complex task and an even more complex piece of advanced mathematics.

When rushing to have something new and exciting ready for the next DIY/HiFi-meeting and everything goes wrong and you have to dust off some old stuff you've showned several times before ...

Or planning well ahead, ordering all the stuff needed, taking time to not rush ... and the most vital part in your project is out of stock everywhere (or sold on eBay at 5 times normal price).

Kaffimann: new DIY-meeting in November!

Or planning well ahead, ordering all the stuff needed, taking time to not rush ... and the most vital part in your project is out of stock everywhere (or sold on eBay at 5 times normal price).

Kaffimann: new DIY-meeting in November!

Thank you Magnus, it would be nice to have some kind of diversion in November.

Will need to evaluate what to bring along.

Do you have any dates?

Will need to evaluate what to bring along.

Do you have any dates?

Here you are: HiFiForum.nu - DIY & Vintage träff i Mölnlycke - Ny programpunkt!

Björn wants us to get a ticket to the event (free if just popping in, some extra money if joining the meals).

(This is the part of DIY I LOVE)

Björn wants us to get a ticket to the event (free if just popping in, some extra money if joining the meals).

(This is the part of DIY I LOVE)

Tube Socket Wiring Style - It Plays!

Then there's getting that small part where it needs to be at the point of use...

I thought of dicing the little board - even right up to the case edge (experimented with an empty board) - no way.

So flying leads it is. These are 22 and 24 MHz oscillators. Hopefully the added 0.5" of lead length doesnt wreck what they're supposed to do. I for sure wont be doing this kind of rework for hire!

Then there's getting that small part where it needs to be at the point of use...

I thought of dicing the little board - even right up to the case edge (experimented with an empty board) - no way.

So flying leads it is. These are 22 and 24 MHz oscillators. Hopefully the added 0.5" of lead length doesnt wreck what they're supposed to do. I for sure wont be doing this kind of rework for hire!

Attachments

Chickened out, basically...

There's two 100 nF film caps that are supposed to help the oscillators 3.3V power delivery, by decoupling. They're a SMD and you have to get them diagonally across pins 1 and 4...

I had 3. One wicked itself to the soldering iron tip and I couldnt get it off for a few seconds - assumed that one was ruined. One I tried to solder leads directly, but in the process of physically bending them to a shape, one ripped off the end. Finally I got them both onto a small piece of FR4 to take the lead bending stress.

So surprised they still both measured 104 nF after taking the beating of getting them "placed" onto something I could physically handle...

I could have dropped those leads directly down onto the oscillator pads, but I just chickened out - I actually tried it on one and, after cutting the leads short, placement just went beyond my abilities. Left it like this - so each lead length is 4 nH instead of 1 - what's the current going in and out of this thing?

So there's an aspect of DIY I hate; having to make the decision between possibly wrecking the whole thing - and just a little bit better.

It's playing Music - Go Vince! (Guaraldi)

There's two 100 nF film caps that are supposed to help the oscillators 3.3V power delivery, by decoupling. They're a SMD and you have to get them diagonally across pins 1 and 4...

I had 3. One wicked itself to the soldering iron tip and I couldnt get it off for a few seconds - assumed that one was ruined. One I tried to solder leads directly, but in the process of physically bending them to a shape, one ripped off the end. Finally I got them both onto a small piece of FR4 to take the lead bending stress.

So surprised they still both measured 104 nF after taking the beating of getting them "placed" onto something I could physically handle...

I could have dropped those leads directly down onto the oscillator pads, but I just chickened out - I actually tried it on one and, after cutting the leads short, placement just went beyond my abilities. Left it like this - so each lead length is 4 nH instead of 1 - what's the current going in and out of this thing?

So there's an aspect of DIY I hate; having to make the decision between possibly wrecking the whole thing - and just a little bit better.

It's playing Music - Go Vince! (Guaraldi)

Attachments

- Home

- Member Areas

- The Lounge

- What part of DIY do you HATE?