It would be nice if we could choose a gas for a sealed subwoofer that would yield much higher compliance by offering a lower 'k' (spring constant – Hooke’s law) for the air-spring that is helping to control and restore the diaphragm. Unfortunately, in a sealed subwoofer system where the captive gas is nominally at ambient atmospheric pressure it will make very little difference which gas we choose since the ideal gas law states PV=nRT (P = pressure, V = volume of gas, n = number of molecules, R = universal gas constant, T = temperature), and n & R are constant. When the diaphragm is displaced it obviously changes V. This slightly alters T but mainly changes P to yield a cone restoring force. Increasing the cabinet size increases the total volume which decreases the change in V for a given cone displacement, thus lowering the restoring P and lowering the resonant frequency of the system. Big box = lower bass.

A note about T: Depending on the thermal coupling of the captive gas with the enclosure, bracing and stuffing materials, T will change somewhere between zero and ‘a tiny amount’ for a given dV/dt.. In other words the system is operating somewhere between adiabatic and isothermic. We add stuffing to a sealed enclosure to give the gas molecules a lot of surface area to thermally couple to, thus biasing the system more toward isothermal operation than adiabatic operation. Isothermal is better since P changes in direct-inverse proportion to V. In adiabatic operation P changes a bit more since the gas is heating during a compression cycle and cooling during a rarefaction ("rarification") cycle – exactly the opposite of what we what since this works to increase the 'k' of the air-spring.

Another option for lowering the frequency response of a sealed subwoofer is to remove the gas altogether and replace it with a low-k alternative to provide the cone restoring force and the force of the atmosphere pushing on the front of the cone. The atmospheric force would be over 1000 pounds for a 12-inch driver. This would obviously be a custom driver and would likely have a honeycomb-core laminated diaphragm and the surrounds could be half-rounds like the ones found in gas-shocks.

-Casey Walsh

A note about T: Depending on the thermal coupling of the captive gas with the enclosure, bracing and stuffing materials, T will change somewhere between zero and ‘a tiny amount’ for a given dV/dt.. In other words the system is operating somewhere between adiabatic and isothermic. We add stuffing to a sealed enclosure to give the gas molecules a lot of surface area to thermally couple to, thus biasing the system more toward isothermal operation than adiabatic operation. Isothermal is better since P changes in direct-inverse proportion to V. In adiabatic operation P changes a bit more since the gas is heating during a compression cycle and cooling during a rarefaction ("rarification") cycle – exactly the opposite of what we what since this works to increase the 'k' of the air-spring.

Another option for lowering the frequency response of a sealed subwoofer is to remove the gas altogether and replace it with a low-k alternative to provide the cone restoring force and the force of the atmosphere pushing on the front of the cone. The atmospheric force would be over 1000 pounds for a 12-inch driver. This would obviously be a custom driver and would likely have a honeycomb-core laminated diaphragm and the surrounds could be half-rounds like the ones found in gas-shocks.

-Casey Walsh

How about Argon ? I don't know it's rho0 value but it is definitely easy to get, is non toxic and non flammable. It could be enclosed in a bag like CV did. I don't know how much it would leak out of a bag but definitely less than Helium I assume.

Regards

Charles

Regards

Charles

Speculative engineering

Just to add a bit more sillyness to our audio hobby. Helium has a habit of escaping out of darn near everything you try to contain it with. In industry this makes H2 very handy for leak checking high vacuum devices.

So for a leaky speaker it would be prudent to design in a constant supply of He, with associated valves, regulators and etc. Lots of spiffy stainless steel plumbing ought to be available surplus thanks to the semiconductor industry.

Concerning ignition (not an issue with He of course). I've worked on quite a few large turbo generators that are filled with H2 as the heat exchange fluid. As long as O2 doesn't get into the mix such that stoichoimetric limits are satisfied, then all that arcing and sparking in a H2 enviornment is of no real concern.

With that in mind we could use any gas we might wish if we keep the speaker enclosure well supplied with gas and the listening area adequately ventilated.😉

Cyclotronguy

Just to add a bit more sillyness to our audio hobby. Helium has a habit of escaping out of darn near everything you try to contain it with. In industry this makes H2 very handy for leak checking high vacuum devices.

So for a leaky speaker it would be prudent to design in a constant supply of He, with associated valves, regulators and etc. Lots of spiffy stainless steel plumbing ought to be available surplus thanks to the semiconductor industry.

Concerning ignition (not an issue with He of course). I've worked on quite a few large turbo generators that are filled with H2 as the heat exchange fluid. As long as O2 doesn't get into the mix such that stoichoimetric limits are satisfied, then all that arcing and sparking in a H2 enviornment is of no real concern.

With that in mind we could use any gas we might wish if we keep the speaker enclosure well supplied with gas and the listening area adequately ventilated.😉

Cyclotronguy

but we already decided that helium would not work. in fact you need a heavier gas to virtually extend the "box"....

I was thinking water could be used instead if you can insulate the electrical parts, and have a sub that's sealed.

You could have the sub top-firing from the water filled chamber, and it fires into a 2nd chamber filled with air, that's ported or vented, like a bandpass.

You could have the sub top-firing from the water filled chamber, and it fires into a 2nd chamber filled with air, that's ported or vented, like a bandpass.

Fun Thread.

I like the idea of bending/breaking things with cheeky, self-important names like "Hoffman's Iron Law." 😉

Exotic enclosure atmospheres aren't a new idea, of course. The earliest patent I'm aware of is from 1957.

Heavy gasses are fine, but they demand a sealed system. The only problem with a sealed system is the fact that we live in a world of fluctuating atmospheric pressure. If your sealed system is a rigid box with a moveable piston, the piston's rest position will change with the weather.

Some have tried to get around this by filling the enclosure somewhat loosely with a sealed bag. In this example, they combined it with a vapor/liquid equilibrium system. Here's another one.

All these are rather complex ways of enhancing compliance. A simpler method, and my favorite, is outlined here. It works by ADsorbing air into a carbon matrix (coconut-husk granular activated charcoal). The only touchy thing about it is GAC's uptake of water. You can allow a pinhole in the sealed enclosure to equalize pressures, but it's recommended to run it through a dessicant canister.

I like the idea of bending/breaking things with cheeky, self-important names like "Hoffman's Iron Law." 😉

Exotic enclosure atmospheres aren't a new idea, of course. The earliest patent I'm aware of is from 1957.

Heavy gasses are fine, but they demand a sealed system. The only problem with a sealed system is the fact that we live in a world of fluctuating atmospheric pressure. If your sealed system is a rigid box with a moveable piston, the piston's rest position will change with the weather.

Some have tried to get around this by filling the enclosure somewhat loosely with a sealed bag. In this example, they combined it with a vapor/liquid equilibrium system. Here's another one.

All these are rather complex ways of enhancing compliance. A simpler method, and my favorite, is outlined here. It works by ADsorbing air into a carbon matrix (coconut-husk granular activated charcoal). The only touchy thing about it is GAC's uptake of water. You can allow a pinhole in the sealed enclosure to equalize pressures, but it's recommended to run it through a dessicant canister.

And, if you try this, don't worry about KEF coming after you for patent infringment. They're just rehashing U.S. patent # 4,657,108.

Bill F.: As always, you present an incredible amount of useful, pertinent information in very little space. I always look forward to your posts!

I have a pending patent for the use of a full or partial vacuum on the enclosed side of the diaphragm and am always quite interested to see how others have attacked the 'self-important' 🙂 law.

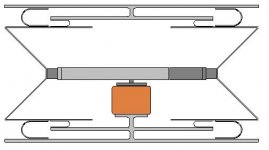

In my vacuum subwoofer prototypes I use half-roll surrounds comprised of a layer of rip-stop nylon (for strength) and a layer of Mylar (to stop in- and out-gassing). It forms an extremely compliant, low loss surround with no limits on excursion. The diaphragm is ½ inch thick honeycomb-core aluminum laminate.

I love this speaker-building stuff!!!

-Casey Walsh

I have a pending patent for the use of a full or partial vacuum on the enclosed side of the diaphragm and am always quite interested to see how others have attacked the 'self-important' 🙂 law.

In my vacuum subwoofer prototypes I use half-roll surrounds comprised of a layer of rip-stop nylon (for strength) and a layer of Mylar (to stop in- and out-gassing). It forms an extremely compliant, low loss surround with no limits on excursion. The diaphragm is ½ inch thick honeycomb-core aluminum laminate.

I love this speaker-building stuff!!!

-Casey Walsh

Interesting! I can't see your drawings for some reason, (could you attach one to a post?) but it sounds a lot like something I was chewing on a couple years ago. Here's an early rough drawing from my sketch archives. This one uses a DC servo motor.

Good luck!

Good luck!

Attachments

I can't see your drawings for some reason

FWIW, If you're using the AlternaTiff plugin, I cant get it to work in FireFox, only in IE.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- What if you build a sub with helium in it?