I'm about to start building these speakers out of mdf: http://www.fostexinternational.com/docs/speaker_comp/pdf/recom_enclose/208ez_enclrev.pdf

What type of glue should I use, or is any wood glue ok?

Would I need to use any screws?

Is it necessary to use some sort of sealent between the joints inside the cabinet?

What type of glue should I use, or is any wood glue ok?

Would I need to use any screws?

Is it necessary to use some sort of sealent between the joints inside the cabinet?

wixy said:What type of glue should I use, or is any wood glue ok?

Any wood glue is fine. I use the yellow stuff but white is fine.

Would I need to use any screws?[/B]

It depends on how many clamps you have. 😉

Is it necessary to use some sort of sealent between the joints inside the cabinet? [/B]

Not if you use lots of glue.

This is your first go at it?

Yep, first go. Thanks for the advice. I plan on getting some clamps and doing it all in stages, so I guess that means I won't need any screws?

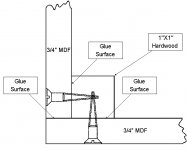

My personal favourite is inside corner blocking and a brad nailer so all but the back of the cabinets have concealed fasteners. No clamps required and fast assembly once the blocks are in place.

Your way is fine if you don't mind waiting. No screws required.

Your way is fine if you don't mind waiting. No screws required.

Cal said:

My personal favourite is inside corner blocking and a brad nailer so all but the back of the cabinets have concealed fasteners. No clamps required and fast assembly once the blocks are in place.

Your way is fine if you don't mind waiting. No screws required.

~~~~~~~~~~~~~~~~~~~~~~~~~~~

I have to agree with Cal on the use of cleats, it's as basic as can be and produces a strong cabinet. I've used nails, screws, clamps, straps, etc., and yet cleats and brads work just as well or better. It's pretty fast, which when you're using carpenter's glue is a factor that should be given a fair amount of consideration.

I like yellow glue best for MDF or ply and Weldwood for dark hardwoods. Weldwood is strong, but needs tight joints. I've used it for boatbuilding and the one criticism I heard for that application is that it isn't water proof because it won't hold if boiled. The late Capt. Pete Culler, boat designer and builder advised: "If you plan on boiling your boat don't use it!"

Seriously, Yellow glue is more than strong enough to preclude any further consideration.

Best Regards,

TerryO

My personal favourite is inside corner blocking and a brad nailer so all but the back of the cabinets have concealed fasteners. No clamps required and fast assembly once the blocks are in place.

Your way is fine if you don't mind waiting. No screws required.

~~~~~~~~~~~~~~~~~~~~~~~~~~~

I have to agree with Cal on the use of cleats, it's as basic as can be and produces a strong cabinet. I've used nails, screws, clamps, straps, etc., and yet cleats and brads work just as well or better. It's pretty fast, which when you're using carpenter's glue is a factor that should be given a fair amount of consideration.

I like yellow glue best for MDF or ply and Weldwood for dark hardwoods. Weldwood is strong, but needs tight joints. I've used it for boatbuilding and the one criticism I heard for that application is that it isn't water proof because it won't hold if boiled. The late Capt. Pete Culler, boat designer and builder advised: "If you plan on boiling your boat don't use it!"

Seriously, Yellow glue is more than strong enough to preclude any further consideration.

Best Regards,

TerryO

wixy said:mdf 208ez_enclrev

Fostex -- and many namy people that have built these in mdf -- recommend that you use plywood.

dave

Slightly off topic, but I think worth noting. MDF (in this country anyway) seems to be non-consistent in density. I have noticed this on the jigsaw, panel saw, and drilling.

If you can, use a good quality outdoor grade ply.

Cleats not only make a stronger joint as others have pointed out, will provide more surface area to seal and make the joints air-tight.

I don't know what's in MDF, but I have noticed special glue (PVA type) and primer labelled for MDF.

FWIW I screw and glue. Too impatient for clamps.

Geoff.

If you can, use a good quality outdoor grade ply.

Cleats not only make a stronger joint as others have pointed out, will provide more surface area to seal and make the joints air-tight.

I don't know what's in MDF, but I have noticed special glue (PVA type) and primer labelled for MDF.

FWIW I screw and glue. Too impatient for clamps.

Geoff.

Geoff H said:FWIW I screw and glue. Too impatient for clamps.

I use brads and blocks. Too impatient for screws and glue. 😉

GLUE

When working with MDF it is best not to depend on glue formulated for wood working . The material is non-porous which keeps wood glue from penetrating the surface. The best glue is Gorilla Glue and although it is costly is worth the price. Clamping is always a good idea because it brings the pieces together with greater force than screws . Most glues are not fillers but are binding agents. Less space means greater bond. I have used Liquid Nails with good success. The construction grade is highly water resistant which in itself indicates its strength . It also is an excellent filler in the event you have gaps. A 1/32 gap can ruin the integrity of the box.

Screwing is OK but you cannot pull together a mismatch of two pieces of MDF with a screw driver.

Line all interior joints with Silicone Caulk.

When working with MDF it is best not to depend on glue formulated for wood working . The material is non-porous which keeps wood glue from penetrating the surface. The best glue is Gorilla Glue and although it is costly is worth the price. Clamping is always a good idea because it brings the pieces together with greater force than screws . Most glues are not fillers but are binding agents. Less space means greater bond. I have used Liquid Nails with good success. The construction grade is highly water resistant which in itself indicates its strength . It also is an excellent filler in the event you have gaps. A 1/32 gap can ruin the integrity of the box.

Screwing is OK but you cannot pull together a mismatch of two pieces of MDF with a screw driver.

Line all interior joints with Silicone Caulk.

Geoff H said:... Cleats not only make a stronger joint as others have pointed out, will provide more surface area to seal and make the joints air-tight....

I glued cleats at all the joints and more than 150 wood screws in each of my subs. 😀

Attachments

Re: GLUE

I have had more than just a few failed glue joints with Elmers yellow wood glue. The MDF structure aways fails before the glue lets go. Of course normal surface preperation are always necessary. And it doesn't hurt to rough up the glue surface with some 100 grit first.

sandstorm33 said:When working with MDF it is best not to depend on glue formulated for wood working . The material is non-porous which keeps wood glue from penetrating the surface. ...

I have had more than just a few failed glue joints with Elmers yellow wood glue. The MDF structure aways fails before the glue lets go. Of course normal surface preperation are always necessary. And it doesn't hurt to rough up the glue surface with some 100 grit first.

Re: GLUE

Hi Sandstorm,

I don't use MDF anymore but that's interesting to hear. I noticed Rodd mentioned the failure actually delaminating the MDF rather than the glue itself. This was my experience in the past. Have you had glue failures? Was it due to an imperfect cut and excess glue in the joint?

I would use almost any other type of caulk before I used silicone. The preparation required doesn't warrant it's use. It adhesion quality is poor to an un-prep'd surface.

If you use continuous inside blocking and a good amount of glue rather than cleats, the caulk will be redundant.

sandstorm33 said:When working with MDF it is best not to depend on glue formulated for wood working .

Hi Sandstorm,

I don't use MDF anymore but that's interesting to hear. I noticed Rodd mentioned the failure actually delaminating the MDF rather than the glue itself. This was my experience in the past. Have you had glue failures? Was it due to an imperfect cut and excess glue in the joint?

Line all interior joints with Silicone Caulk. [/B]

I would use almost any other type of caulk before I used silicone. The preparation required doesn't warrant it's use. It adhesion quality is poor to an un-prep'd surface.

If you use continuous inside blocking and a good amount of glue rather than cleats, the caulk will be redundant.

Cal-The first speaker box for me came in 1961 , and was designed by GP Augsberger. It had continuous blocking and screws everywhere. The glues available then were few and thus it was necessary to secure everything twice over. There was no MDF then ,as far as I know but we used particule board glued with Elmers. Later came Titebond and that was an improvement. Never had a laminar failure.

My biggest project was the SWAN Four setup done in the late 80's . Used no blocks ,used MDF with Titebond . They are still humming. So who knows. I am just finishing a pair of quaterwave tubes made of 3/4 MDF done with Gorilla GLue and 1/4 inch dowels. The dowels are there to keep things from moving. I am fortunate enough to have a good rack of pipe clamps which I think are indispensible in Speaker Building. Again the most important aspect of the whole process is a good fitup of the pieces that in the end produce an airtight environment.

My biggest project was the SWAN Four setup done in the late 80's . Used no blocks ,used MDF with Titebond . They are still humming. So who knows. I am just finishing a pair of quaterwave tubes made of 3/4 MDF done with Gorilla GLue and 1/4 inch dowels. The dowels are there to keep things from moving. I am fortunate enough to have a good rack of pipe clamps which I think are indispensible in Speaker Building. Again the most important aspect of the whole process is a good fitup of the pieces that in the end produce an airtight environment.

Holy doodle, you're old enough to be my...

...brother.

My first meager little box didn't come till '73. I feel like a pup all of a sudden. 😉

Yes, I agree that a good fit and prep'd surface are very important for a 50 year joint.

...brother.

My first meager little box didn't come till '73. I feel like a pup all of a sudden. 😉

Yes, I agree that a good fit and prep'd surface are very important for a 50 year joint.

While I am new to speaker buildiing, I

am a carpenter of 25 years. I use alot of titebond II or the use of PL premium constuction adhesive is a sure bet for glueing or sealing anything. If you glue a brick with it, it is there forever...I have personally watched with a smile a crue or II tearing up a deck misshap done with PL constuction adhesive...all the happens is torn Joist..TJI or what ever..amazing stuff. but for nice wood project, hardwoods etc, I like tite bond products, never failed me.. I dislike Gorilla glue for finish work,, but for hidden adventures it is good stuff..

am a carpenter of 25 years. I use alot of titebond II or the use of PL premium constuction adhesive is a sure bet for glueing or sealing anything. If you glue a brick with it, it is there forever...I have personally watched with a smile a crue or II tearing up a deck misshap done with PL constuction adhesive...all the happens is torn Joist..TJI or what ever..amazing stuff. but for nice wood project, hardwoods etc, I like tite bond products, never failed me.. I dislike Gorilla glue for finish work,, but for hidden adventures it is good stuff..

Re: Re: What glue to use?

Why is this the case? What negative effect will result from using mdf rather than ply?

I would have liked to use plywood, but the only reason I chose mdf was because it was far cheaper and this my first diy project, so I am more likely to make mistakes.

planet10 said:

Fostex -- and many namy people that have built these in mdf -- recommend that you use plywood.

dave

Why is this the case? What negative effect will result from using mdf rather than ply?

I would have liked to use plywood, but the only reason I chose mdf was because it was far cheaper and this my first diy project, so I am more likely to make mistakes.

Also, does anyone think I can get away with this project using just glue, given that there is so much internal bracing?

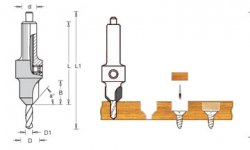

Would biscuit joints be a good idea for the external sheets?

Would biscuit joints be a good idea for the external sheets?

Re: GLUE

I thought MDF was mega-porous, that's why it's such a problem in damp conditions.

Bad advice IMO. Silicone gasses off nasty vapours which rot speakers - plenty of posts on here attesting to that. Also it's not necessary to caulk a box if it's been glued ok.

For the record I now use Extramite (formerly Cascamite) powdered resin wood glue as I found PVA too rubbery which gave problems with the finishing work where joints were not perfect.

sandstorm33 said:When working with MDF it is best not to depend on glue formulated for wood working . The material is non-porous which keeps wood glue from penetrating the surface.

I thought MDF was mega-porous, that's why it's such a problem in damp conditions.

sandstorm33 said:Line all interior joints with Silicone Caulk.

Bad advice IMO. Silicone gasses off nasty vapours which rot speakers - plenty of posts on here attesting to that. Also it's not necessary to caulk a box if it's been glued ok.

For the record I now use Extramite (formerly Cascamite) powdered resin wood glue as I found PVA too rubbery which gave problems with the finishing work where joints were not perfect.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- What glue to use?