I don't have anything fancy. I've used a pair of pliers held closed with a rubber band.

I have a third hand like the one in post #2. I used some rubber tubing slid over the jaws to protect the work from scratches.

I have a third hand like the one in post #2. I used some rubber tubing slid over the jaws to protect the work from scratches.

I also use Panavise, namely this one:

Invalid Request

I bolted it down to a piece of wood and glued a little pieces of rubber mat (actually the thing that's left of those self adhesive little rubber feet after use) on each corner on the underside of the wood piece. Now I can move the vice away when needed, but it won't slide on the table.

Invalid Request

I bolted it down to a piece of wood and glued a little pieces of rubber mat (actually the thing that's left of those self adhesive little rubber feet after use) on each corner on the underside of the wood piece. Now I can move the vice away when needed, but it won't slide on the table.

I found that soldering two wire ends is difficult with bare hands. Nowadays, I wrap a single strand wire on the joint and then solder it.

Gajanan Phadte

Edit:I am getting an itch to construct the TVIs wooden support at post #14

Gajanan Phadte

Edit:I am getting an itch to construct the TVIs wooden support at post #14

Last edited:

I now wish that third arm wasn't removed at birth. 🙁

I do use a small bench vise but the jaw spread isn't usually enough. Normally, I muck around so much it annoys the tripe out of me.

I do use a small bench vise but the jaw spread isn't usually enough. Normally, I muck around so much it annoys the tripe out of me.

Last edited:

I'll use a Panavise board holder if I'm desoldering and need to use a soldering iron on one side of the board and a solder sucker on the other side.

A "third hand" is invaluable for soldering connectors. A bead of RTV (silicone) on the cast base stops it from sliding around on the workbench.

A "third hand" is invaluable for soldering connectors. A bead of RTV (silicone) on the cast base stops it from sliding around on the workbench.

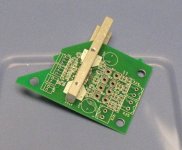

alligator clip pcb holder

I have one just like that, but i always manage to tip it over ..i guess i could add a flat piece of board and glue the base but then, the little clips scratch the boards...i am not really fond of this design. I put short lengths of heat shrink tube over the clip jaws - it stops the scratching, but it doesn't stop the whole thing from tipping over! I think I'll copy your idea and glue a board on he base to increase the footprint.

I use painters tape & small steel blocks to hold things in place. I also knock off the back pole piece of blown speakers for weights and knock off the maqnet which holds all the screws when repairing. A good set of reading glassses help. Of course I'm reading this thread to see what everybody else is doing.... I don't have any local soldering buddies...

I like it. I might try to devise a holder for the third side of the board, just using a rubber pad and spring tension.

what do you use to hold the pcb when soldering?

I've allways used Blu-Tack

Blu-Tack - Wikipedia, the free encyclopedia

It's the handiest and the most versatile solution I've encountered 😀 Can find it in any supermarket, too.

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- what do you use to hold the pcb when soldering?