Hi everyone, I have got a thorens TD160 with a original tonearm

but sadly bent at the rear part, should anyone has the same experience and tell me what can I do, to find another thorens tonearm in HONG KONG is quite difficulty.

I perfer to disassembly it and re-straight it.

Thanks,

CHOW

but sadly bent at the rear part, should anyone has the same experience and tell me what can I do, to find another thorens tonearm in HONG KONG is quite difficulty.

I perfer to disassembly it and re-straight it.

Thanks,

CHOW

Attachments

The first thing I would do is strip it down completely then you can see what the real damage is. What's the arm made of?

yes you must strip it down ,then look what you can to repair damage

post picture when you dismantle it .

be careful with bearings and wiring

to pink-Thorens,alu tube.

post picture when you dismantle it .

be careful with bearings and wiring

to pink-Thorens,alu tube.

What can I do to a bent tonearm

Hi Chow

This looks like a nice enough arm to have a go at fixing. The armtube looks like a thinwall alu tube?

Depending on how the armwires enter the armbase (by plug and socket or directly), you'll have to remove the complete arm from the tt. Once this is done, remove the armweight. Is there a spiral grooved plastic stub for the weight at the back? If the stub is hollow, there'll be a selftapper inside to remove the stub. There should be 5 wires in the armbase: red, green, white and blue and a 5th, which should be black, connecting the armbase to the armtube itself.

Once you have removed the arm from the tt, removed the weight stub etc, try to post more pics like the esteemed pinkmouse suggested, so we can assist you further.

Whatever will have to happen, the armwires will have to be removed from where they could get damaged. Most likely, the armtube will also have to be removed from its pivot. With a little bit of luck, a tube bending spring could be inserted and the bend carefully pressed in a soft jaw vise or a lathe headstock chuck for better trueing.

Good luck

bulgin

Hi Chow

This looks like a nice enough arm to have a go at fixing. The armtube looks like a thinwall alu tube?

Depending on how the armwires enter the armbase (by plug and socket or directly), you'll have to remove the complete arm from the tt. Once this is done, remove the armweight. Is there a spiral grooved plastic stub for the weight at the back? If the stub is hollow, there'll be a selftapper inside to remove the stub. There should be 5 wires in the armbase: red, green, white and blue and a 5th, which should be black, connecting the armbase to the armtube itself.

Once you have removed the arm from the tt, removed the weight stub etc, try to post more pics like the esteemed pinkmouse suggested, so we can assist you further.

Whatever will have to happen, the armwires will have to be removed from where they could get damaged. Most likely, the armtube will also have to be removed from its pivot. With a little bit of luck, a tube bending spring could be inserted and the bend carefully pressed in a soft jaw vise or a lathe headstock chuck for better trueing.

Good luck

bulgin

Thanks for your suggestion, I think it is worth to have a try, will post pict once I have strip it down.

Regards,

CHOW

Regards,

CHOW

BTW If someone can poitnt out where can I get the assembly

diagram of this tonearm( I dont know the exact model, maybe a

TP16).This surely will make the job more easy.

Thanks,

CHOW

diagram of this tonearm( I dont know the exact model, maybe a

TP16).This surely will make the job more easy.

Thanks,

CHOW

If possible, strip the arm down so that you just have the tube. Plug one end and fill the tube with moist fine sand. Pack it in there good. Plug the open end. Now you can bend the tube without fear of crimping it. I have used this method on tubing successfully several times.

Yes, it looks like a most safe way to bend or straighten a hollow tube, surely I will take a try provided I can de-assembly the tone arm.

Regards,

CHOW

Regards,

CHOW

It looks like it ought to be fixable (with care). I would check to see if there is any associated bearing damage to be repaired, too, since it probably took a pretty good whack to bend it that much.

Hi,

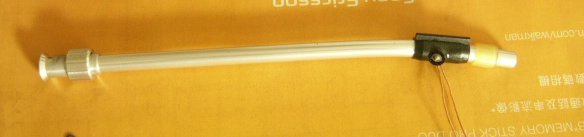

I have strip the tonearm and find an arm tube like this,

I manage to make it quite straight and assembly the whole thing, it now play LPs well, but can any one tell me where can I get a 50Hz motor pulley for the TD160 because I get one TT with 117v 60Hz motor, how stupid I am.

Thanks

CHOW

I have strip the tonearm and find an arm tube like this,

I manage to make it quite straight and assembly the whole thing, it now play LPs well, but can any one tell me where can I get a 50Hz motor pulley for the TD160 because I get one TT with 117v 60Hz motor, how stupid I am.

Thanks

CHOW

Attachments

well done!

regarding pulley....I have no any usefull info ,except that you can try with adittional plastic sleeve around existing pulley

regarding pulley....I have no any usefull info ,except that you can try with adittional plastic sleeve around existing pulley

If you need thinwall aluminium tube you may by an arrow from an armourer they have many size and types...may find a fair replacement tube

Thanks a lot,

About the tube I think I can get a replacement from a badminton racket shaft. But I don't know how to detach those parts attached to the tube.i.e. the part to join the head shell, the part to form the vertical bearing. Can anyone here show me how to strip it.

Best regards,

CHOW

About the tube I think I can get a replacement from a badminton racket shaft. But I don't know how to detach those parts attached to the tube.i.e. the part to join the head shell, the part to form the vertical bearing. Can anyone here show me how to strip it.

Best regards,

CHOW

I need help

Hi,

As suggested, I strip the whole tone arm, and found where the tube was bent, and I want to replace the tube with a badminton racket shaft, at the meantime I don't how to detach the sleeve-the one where the pivot locate and the signal thread come out from the tube as well as the adaptor where the head shell attach to the tube. Can anyone show me how to safely detach these parts and then I can diy anthor one to make my TT sing.

Thanks,

CHOW

Hi,

As suggested, I strip the whole tone arm, and found where the tube was bent, and I want to replace the tube with a badminton racket shaft, at the meantime I don't how to detach the sleeve-the one where the pivot locate and the signal thread come out from the tube as well as the adaptor where the head shell attach to the tube. Can anyone show me how to safely detach these parts and then I can diy anthor one to make my TT sing.

Thanks,

CHOW

according to your picture - you can save this arm tube.... no need for changing the tube

use only hands and put towel on bench,if you must use it as support during straightening

been there,done that - with EMT arm...........

use only hands and put towel on bench,if you must use it as support during straightening

been there,done that - with EMT arm...........

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- what can I do to a bent tone arm