I'm working on a dead Wadia 21 and I am betting that the laser is dead but how do I tell for sure?? I have read many post's about the Teac servo boards having problems.

Symptoms, Insert cd, sled traverses towards spindle, tries to focus 3 times then sled moves to end of travel away from spindle. disc never spins.

I used my cell phone camera to look at the lens while the laser is trying to focus and weakly i can see that the laser is in fact turning on and off.

I have verified that all supplies are working and that the proper PSU voltages are present at each IC.

The spindle motor works when an external voltage is applied. I have traced through the TEAC VRDS T1 schematic (which is very very close to the TEAC board in the 21) and no spindle signal is sent to the spindle motor controller from the Sony CXD2500 IC. But it appears to brake if you spin the disc by hand and open the tray. So I am assuming the motor control circuity is ok.

I see no RF coming out of the laser transport board. I am assuming it would only be seen if the disc was playing.

So the question is how do I determine if in fact the laser is just so dead it can't see the disc??

Zc

Symptoms, Insert cd, sled traverses towards spindle, tries to focus 3 times then sled moves to end of travel away from spindle. disc never spins.

I used my cell phone camera to look at the lens while the laser is trying to focus and weakly i can see that the laser is in fact turning on and off.

I have verified that all supplies are working and that the proper PSU voltages are present at each IC.

The spindle motor works when an external voltage is applied. I have traced through the TEAC VRDS T1 schematic (which is very very close to the TEAC board in the 21) and no spindle signal is sent to the spindle motor controller from the Sony CXD2500 IC. But it appears to brake if you spin the disc by hand and open the tray. So I am assuming the motor control circuity is ok.

I see no RF coming out of the laser transport board. I am assuming it would only be seen if the disc was playing.

So the question is how do I determine if in fact the laser is just so dead it can't see the disc??

Zc

Last edited:

Look for a low value resistor in the laser power circuit that you can measure the volts across and determine the current. Typically around 46 to say 55 milliamps but is pickup dependent.

I would expect to see RF signal of some sort if you spin the disc by hand while the laser is lit (during focus search). It may only be a "bounce" in the level but you should see something.

I would expect to see RF signal of some sort if you spin the disc by hand while the laser is lit (during focus search). It may only be a "bounce" in the level but you should see something.

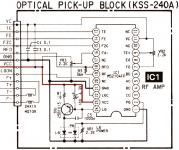

The KSS240 makes it difficult to access the 10 ohm with it being on the pickup 🙁

I did a thread on the KSS240 in a Sony player and all the adjustments which you perhaps have seen. There's a fair chance your pickup is faulty.

http://www.diyaudio.com/forums/digital-source/226288-sony-cdp790-kss240-restoration-project.html

I did a thread on the KSS240 in a Sony player and all the adjustments which you perhaps have seen. There's a fair chance your pickup is faulty.

http://www.diyaudio.com/forums/digital-source/226288-sony-cdp790-kss240-restoration-project.html

Thanks for that link! that's some good reading! I also found a post on the web that makes me feel a little bit better in that it says that the disc won't spin unless focus is found. once focus is found then it should spin the disc up. Which ok I might believe. But I also found a posting elsewhere that mentions that the sled parking away from the spindle could mean the transport is in "lock" mode which I have no idea what that means as there is no locking mech I can see. But of all the cd players I have ever worked on I have never seen one that parks the laser sled away from the spindle. Not sure if that is normal or not??

Yes, the disc won't spin until focus is found. Its easier focusing on a stationery object. I would have though though that if you looked at the RF test point during this time and did spin the disc by hand you would see some kind of output bounce. It might "prove" that at least there is some "laser light" emitted. When laser diodes fail or are fed a lower than normal current they can still emit light but they function more as a side emitting LED rather than a laser. The laser action occurs rapidly and dramatically as current increases past a critical threshold.

All the players I've seen too (apart from unpowered swing arms) have the laser at the spindle motor. Move the sled by hand with it off and then power up and it should return to the spindle motor. You can get an odd leaf switch thats a bit dicky or even phsically broken but things like that are rare and easily spotted.

All the players I've seen too (apart from unpowered swing arms) have the laser at the spindle motor. Move the sled by hand with it off and then power up and it should return to the spindle motor. You can get an odd leaf switch thats a bit dicky or even phsically broken but things like that are rare and easily spotted.

There are basically three major weak links in that vrds, the loading gears, the spindle motor and the laser. Seems the gears are fine so far(bit of a miracle). If the laser is doing as you say, then the spindle motor is not being told to start, as focus is failing, so won't know about that until focus is achieved. With extremely rare exceptions, KSS240's don't drift out of range, but are simply either good or bad, or lens is very dirty. Assuming a clean lens, your are very, very likely needing a new laser. I would say you are wasting your time looking for other faults until you try one. I'd say it is easily 95% likely that the new laser will cure it. One preventive step on the motor you should take, though, is to give it a "silicone treatment", meaning find an electrically safe silicone-based spray lubricant, then spray a small shot of it into each of the two slots in the motor that will be shown when the dress plate is removed from the top. This will dislodge & prevent carbon buildup on the commutator, and generally cure any non-working motor of this type.

I will take a look at the RF test point and spin the disc by hand and see if i can get anything from it.

I have moved the sled by hand as you suggested and it will stay at the spindle and try and focus, then moves away from the spindle once it can't find the disc. Now unless the switches are wired backwards...which it is very clear someone has been in here before...But if they were wired backwards then you would think that when you open and close the drawer, that the spindle would just sit there, but it always moves to the spindle and tried to focus.

I have moved the sled by hand as you suggested and it will stay at the spindle and try and focus, then moves away from the spindle once it can't find the disc. Now unless the switches are wired backwards...which it is very clear someone has been in here before...But if they were wired backwards then you would think that when you open and close the drawer, that the spindle would just sit there, but it always moves to the spindle and tried to focus.

I keep seeing post's that mention the CXD2500 dying but no further info on why or how or symptoms of a dead 2500??

There are basically three major weak links in that vrds, the loading gears, the spindle motor and the laser. Seems the gears are fine so far(bit of a miracle). If the laser is doing as you say, then the spindle motor is not being told to start, as focus is failing, so won't know about that until focus is achieved. With extremely rare exceptions, KSS240's don't drift out of range, but are simply either good or bad, or lens is very dirty. Assuming a clean lens, your are very, very likely needing a new laser. I would say you are wasting your time looking for other faults until you try one. I'd say it is easily 95% likely that the new laser will cure it. One preventive step on the motor you should take, though, is to give it a "silicone treatment", meaning find an electrically safe silicone-based spray lubricant, then spray a small shot of it into each of the two slots in the motor that will be shown when the dress plate is removed from the top. This will dislodge & prevent carbon buildup on the commutator, and generally cure any non-working motor of this type.

Thanks, I did disconnect the spindle motor from the servo board and applied 3v dc to the motor and it did spin! I also reversed the polarity and made sure it would spin backwards as well. so I feel the motor is good. I traced through the whole motor control circuit all the way to the CXD2500 IC and i see no life on that line so I do believe the motor is not being told to start.

Assuming that this laser is toast and will need to be replaced. I wonder if i could turn the laser power up and see if it will at least show any signs of life? If i could at least get it to focus enough to spin the disc and try and read the TOC then i would just yank and replace the laser. I just don't want to waste ANY $$ (i have zero) buying a laser only to find out that the servo board it toast. if i could at least see some signs of life then i would feel much better investing in it.

It is pretty darn rare for CXD2500 to fail without lightning damage. I have only had to replace ONE in the last 20+ years of prof. service work. Your symptoms do not indicate any reason to suspect it's bad. It is the signal proc, not servo control, so a bad one will not manifest, if it's not running hot, until you have a cd playing, and either no sound or distorted sound/noise coming out. You also won't see any rf output from a laser that could not get focus.

These lasers are pretty inexpensive, even from reputable sources. In the USA, most reliable sources are MCM and Parts Express, which should both have stock of these. Dalbani is also good, but does carry 'generics', but always indicates when parts are thus. The 240 usually has perfectly good laser power when defective, as it seems to always be the receiving end of it that goes bad.

It is pretty darn rare for CXD2500 to fail without lightning damage. I have only had to replace ONE in the last 20+ years of prof. service work. Your symptoms do not indicate any reason to suspect it's bad. It is the signal proc, not servo control, so a bad one will not manifest, if it's not running hot, until you have a cd playing, and either no sound or distorted sound/noise coming out. You also won't see any rf output from a laser that could not get focus.

ahhh Ok, I will order a new laser then! I might have one at work, will check on Monday!

These lasers are pretty inexpensive, even from reputable sources. In the USA, most reliable sources are MCM and Parts Express, which should both have stock of these. Dalbani is also good, but does carry 'generics', but always indicates when parts are thus. The 240 usually has perfectly good laser power when defective, as it seems to always be the receiving end of it that goes bad.

That might explain why these just stop working suddenly?

That might explain why these just stop working suddenly?

Yes, it would. You should also check that there are no cracks in the conductors of the ribbon cable that goes to it, particularly anywhere the ribbon is or has been folded.

Only had a few minutes tonight, turning the laser power control made no difference just as you suggested. I will order a new laser and see what happens.

OH YEAH! this laser is TOAST! I disassembled the transport tonight and pulled the laser block out and right away I could see that the circuit board under the three trimmer pots was discolored. removing the circuit board shows the transistor that controls the laser and a resistor next to it is burned to a crisp! not charred but very very discolored and obviously overheated. so yeah, new laser time.

Zc

Zc

Wow, I can't recall a single time seeing a Sony laser visibly damaged like that, other than first gen KSS100's with melted top ends from the focus/tracking drive hybrid IC's shorting. Would not have expected that, but sure explains the sudden death.

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- Wadia 21 Dead laser or servo problems?