planet10 said:For some reason it wouldn't let me attach the pic....

An externally hosted image should be here but it was not working when we last tested it.

That's a neat way to blend the driver with the box, can you take the driver out if it needs replacing?

planet10 said:

Ah! Now I remember. I never get smooth responses like that when they are boxed.

That's a neat way to blend the driver with the box, can you take the driver out if it needs replacing?

Yes, drivers look much neater when the flange and screws/bolts are concelaled!

That could be done by making the speaker as usual, then adding an extra panel on top of it. If you use screws and key slots, you can slide the extra panel over the front but be able to remove it to get at the driver if necessary. 😉

Nuuk said:

Yes, drivers look much neater when the flange and screws/bolts are concelaled!

That could be done by making the speaker as usual, then adding an extra panel on top of it. If you use screws and key slots, you can slide the extra panel over the front but be able to remove it to get at the driver if necessary. 😉

Won't there be vibration coupling if you do that?

Won't there be vibration coupling if you do that?

Not f you out a bit of thin cork or similar at the back of the 'extra' panel.

And alternative is to mount the driver from the rear and have a removeable rear panel.

Vikash: I like the look of those. Classic styling.

It's true. I've ripped one apart, and the voice coil is 7mm while the gap is 6mm. In this case, .5mm isn't as bad as it seems, because of the large gap height. The speaker may run out of Xmax fast, but it overloads slowly and gracefully because the tall gap has a high percentace of coil in it at any give time.

So while the Xmax is .5mm, you'll generally get 1.5mm one way before distortion starts to be audible.

richie00boy said:I see on your website that you sell the Tang Band's. What made you choose this model from the large range by Tang Band and is the 0.5mm Xmax quoted on your website correct? It seems uselessly low.

It's true. I've ripped one apart, and the voice coil is 7mm while the gap is 6mm. In this case, .5mm isn't as bad as it seems, because of the large gap height. The speaker may run out of Xmax fast, but it overloads slowly and gracefully because the tall gap has a high percentace of coil in it at any give time.

So while the Xmax is .5mm, you'll generally get 1.5mm one way before distortion starts to be audible.

Attachments

The B3S on the other hand, has a 9mm long voice coil and a relatively small 3mm gap. So it gets more Xmax for starters, but when distortion sets in, it comes on fast.

The B3S and 871 are a little closer in realistic output than their Xmax figures say, though the B3S still has effectively double the swept volume before distortion sets in.

These drivers took very different routes to voice coil and gap configurations. The 871's larger gap is what gives it a little more efficiency, though efficiency is less important than ultimate output potential with speakers of this low power handling. (unless you are using them for a midrange)

Ps. Dave: I like what you did with the Aura NS3. Rear mounting looks very nice. I might have to try that with the next set I do. (Possibly 4 per side in a MMTMM)

The B3S and 871 are a little closer in realistic output than their Xmax figures say, though the B3S still has effectively double the swept volume before distortion sets in.

These drivers took very different routes to voice coil and gap configurations. The 871's larger gap is what gives it a little more efficiency, though efficiency is less important than ultimate output potential with speakers of this low power handling. (unless you are using them for a midrange)

Ps. Dave: I like what you did with the Aura NS3. Rear mounting looks very nice. I might have to try that with the next set I do. (Possibly 4 per side in a MMTMM)

Attachments

soongsc said:That's a neat way to blend the driver with the box, can you take the driver out if it needs replacing?

I haven't seen these speakers yet -- i believe the back comes off.

I do like the drivers mounted from behind.

dave

Attachments

I do the same kind of mouting with mine, I can easily try other units or replace the existing ones if I put my finger through the cones.

To try a new pair or when I first listen I use a ring of Blue Tack and push it down heavily it's surprising how much effort is needed to part two pieces of wood held together like this.

Rgds - Jem

To try a new pair or when I first listen I use a ring of Blue Tack and push it down heavily it's surprising how much effort is needed to part two pieces of wood held together like this.

Rgds - Jem

Attachments

Vikash said:Ph-en-om-en-al!

Partnered with my new DAC (ala Peter Daniel) and LM3875 amp my music collection has been given a new lease of life 😉 The bad recordings sound really bad now, and the good ones are mesmerizing.

I'm a fullrange beliver now. Which driver next...

Nice project!!

I'm also leaning towards this TB unit and some project - I just have to decide - would it be bookshelf model or floorstanding - I think that in the case of FS - you can still get enough low frequences without additional SW - or am I wrong??

Btw - if understood correctly - box is just coated with several layers of oil - no lacquer etc??

Re: Re: W3-871S Monitors Finished!

With an Fs in the neighborhood of 130 hz, it doesn't matter what box you use, you aren't getting a whole lot of bass.

dave

Stabist said:I think that in the case of FS - you can still get enough low frequences without additional SW - or am I wrong??

With an Fs in the neighborhood of 130 hz, it doesn't matter what box you use, you aren't getting a whole lot of bass.

dave

Yes, just three coats of danish oil. And you will need a sub if the bottom end is important to you. I don't mind without for bedroom or surround application.

Thanks Dave 😉.

A little early for me to reveal the whole kit thing, so much to do yet, but what the heck...

The speaker posted by Dave is assembled from one of my kits. They feature all Baltic Birch ply construction, mitre(miter-usa) lock joints, removable back for access to the driver and the whole kit is build with fool-resistant assembly technique. Optionally, I will offer a second front baffle with mounting holes and binding posts to replace the rear baffle for bipole operation, extra rear baffles for those who want to try different alignments, ie. ported, aeperiodic...etc. And, most likely, I will offer a learning/experimenters kit with all alignment options and tweak suggestions so one can hear the effects each has on the overall sound.

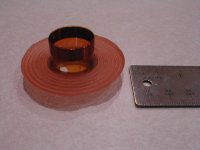

As to driver mounting I use short #8 robertson screws from behind the baffle, but my most trusted technique is adhesive, specifically, silicone based. With the back removed the driver is very easy to access for tweaking, wiring...etc. and if removal is necessary (due to speaker damadge or whatever) they pull off relatively easily and the silicone cleans up with only slight effort. The baffle is 5/8" thick and the driver is mounted in a recess to bring the face even with the front of the baffle. The front and rear baffles are CNC machined.

The kits are complete, that is to say to assemble them one will only need glue, screwdriver and soldering iron or crimper. The finish will be entirely up to the user, including sanding. The panels fit very closely, there should be no need for filler unless the user gets junk in a joint.

I am planning on selling ten "review/ 'consumer' test" pairs to the first ten participating forum members at a discounted price. After that forum members will still receive a discount albeit not so severe, a profit portion will be donated to this forum. Final details will be announced soon.

Oh, and they sound pretty darn impressive for what they are. I don't want to give my opinion other than that, I don't wish anyone buy these because I said "they sound better than ____ "and be disappointed...I'll let the users damn or praise them.

A little early for me to reveal the whole kit thing, so much to do yet, but what the heck...

The speaker posted by Dave is assembled from one of my kits. They feature all Baltic Birch ply construction, mitre(miter-usa) lock joints, removable back for access to the driver and the whole kit is build with fool-resistant assembly technique. Optionally, I will offer a second front baffle with mounting holes and binding posts to replace the rear baffle for bipole operation, extra rear baffles for those who want to try different alignments, ie. ported, aeperiodic...etc. And, most likely, I will offer a learning/experimenters kit with all alignment options and tweak suggestions so one can hear the effects each has on the overall sound.

As to driver mounting I use short #8 robertson screws from behind the baffle, but my most trusted technique is adhesive, specifically, silicone based. With the back removed the driver is very easy to access for tweaking, wiring...etc. and if removal is necessary (due to speaker damadge or whatever) they pull off relatively easily and the silicone cleans up with only slight effort. The baffle is 5/8" thick and the driver is mounted in a recess to bring the face even with the front of the baffle. The front and rear baffles are CNC machined.

The kits are complete, that is to say to assemble them one will only need glue, screwdriver and soldering iron or crimper. The finish will be entirely up to the user, including sanding. The panels fit very closely, there should be no need for filler unless the user gets junk in a joint.

I am planning on selling ten "review/ 'consumer' test" pairs to the first ten participating forum members at a discounted price. After that forum members will still receive a discount albeit not so severe, a profit portion will be donated to this forum. Final details will be announced soon.

Oh, and they sound pretty darn impressive for what they are. I don't want to give my opinion other than that, I don't wish anyone buy these because I said "they sound better than ____ "and be disappointed...I'll let the users damn or praise them.

am planning on selling ten "review/ 'consumer' test" pairs to the first ten participating forum members at a discounted price. After that forum members will still receive a discount albeit not so severe, a profit portion will be donated to this forum. Final details will be announced soon.

I would certinley be interested in a pair of your review speakers, if you are looking for more experince builders its no problem 🙂

Either way I can't wait to see this project progressing 🙂

n00beR said:

I would certinley be interested in a pair of your review speakers, if you are looking for more experince builders its no problem 🙂

Either way I can't wait to see this project progressing 🙂

Me too. 🙂 I'm currently looking for some computer speakers. For some reason, very time I finish a set, someone in the family gets a new computer. Who do you think "lends" his latest project ?

These on would be mine. All mine...

Cool, thanks for the interest guys. i've already put a pair out into the local community which should yield some feedback for you guys to check out. This week, I'm heading out to the coast to hang out with, and deliver a pair of speakers to Dave (planet_10), no doubt he'll have some feedback . When I get back I'll start a new thread in the Bazaar with all the details, and stop jacking this thread.

Nice speakers Vikash, I like the exposed plys, for the demo pairs I chose to fill the grain and paint the baffles black, more people seemed to ike that, but personally, i like the plys..with the rear mount the plys create a bullseye around the driver, looks cool. Recently I rebuilt some vintage equipment, ie. a Sansui tuner... and swapped out the factory wooden sides for Baltic Birch with exposed plys...I'm also designing new furniture that will be made of BB with exposed edges...the Scandinavian look.

Nice speakers Vikash, I like the exposed plys, for the demo pairs I chose to fill the grain and paint the baffles black, more people seemed to ike that, but personally, i like the plys..with the rear mount the plys create a bullseye around the driver, looks cool. Recently I rebuilt some vintage equipment, ie. a Sansui tuner... and swapped out the factory wooden sides for Baltic Birch with exposed plys...I'm also designing new furniture that will be made of BB with exposed edges...the Scandinavian look.

Thanks Ropie 😀

Illusus, are you using any filters? I am especially intersted in that driver if I can prevent contamination with filter components.

The ply does look very nice. I was quietly suprised, and it's a pleasure to work with and finish compared to MDF.

I'm guessing overseas carriage will be a lot for your project which makes it a big tease for many of us 😉 They cabs look superb

Cheers Zach for popping in with that info. I always find it strangely satisfying to see drivers ripped apart.

Illusus, are you using any filters? I am especially intersted in that driver if I can prevent contamination with filter components.

The ply does look very nice. I was quietly suprised, and it's a pleasure to work with and finish compared to MDF.

I'm guessing overseas carriage will be a lot for your project which makes it a big tease for many of us 😉 They cabs look superb

Cheers Zach for popping in with that info. I always find it strangely satisfying to see drivers ripped apart.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- W3-871S Monitors Finished!