My apologies; I purposely omitted the obvious, that the mass rule of thumb stated is based around industry standard viscoelastic damping materials, not toffee/carpet/chewing gum...😉But there's no physical basis for that rule - viscous friction isn't directly related to mass or density.

That's interesting, thanks.A general rule used in industry is that the mass of damping material should roughly equal the mass of the panel to be damped

It explains what I've always guess without ever being able to detail it to myself. 😉

I'm not aware of the lack of this rule and therefore I kindly ask you to detail it for me, please.But there's no physical basis for that rule - viscous friction isn't directly related to mass or density

However, if I may, I guess that "viscous friction" is related to the characteristics of a material, and among its characteristics there will certainly also be mass.

So I wonder if a material with high "viscous friction" characteristics doesn't also have high damping capacity and high mass. 🤔

Tungsten has high mass and no viscous friction, foam rubber has high viscous friction and low mass.

I got it, thanks.

But then I conclude that "viscous friction" is not the first characteristic I look for in a dampening material to reduce the resonances of a panel.

Furthermore, it's clear enough that no one would use tungsten to dampen the resonance of a metal panel.

So, in my eyes, the mass of a dampening material does matter more than its "viscoud friction" factor.

Did I omit any step?

But then I conclude that "viscous friction" is not the first characteristic I look for in a dampening material to reduce the resonances of a panel.

Furthermore, it's clear enough that no one would use tungsten to dampen the resonance of a metal panel.

So, in my eyes, the mass of a dampening material does matter more than its "viscoud friction" factor.

Did I omit any step?

To dampen a resonance a material has to dissipate the energy by some mechanism, usually as heat via friction (solid or viscous) - this is what a shock-absorber in car suspension does and it doesn't use mass to do its job, it forces oil through small channels to generate heat by friction. The only reason mass is required fundamentally is to absorb and spread the heat generated, it doesn't directly do damping.

Marigo sells these very cool constrained layer damping VTS dots, different sizes for everything from the bottom of electron tubes in between the pins to the wall, to speakers to electronics chasses to glass windows, you name it.

Last edited:

Hello All,

Thanks for all the suggestions and comments.

I never would have thought of a product made for the automobile industry!

The Mortite Caulking idea is interesting, but I wonder about bonding to the underside of a chassis top panel?

The Butyl deadening material looks interesting, and at 10 sq ft for $27.00 is priced right.

Doing the “Google thing”, I came up with AcousTech’s vibration dampening material sold by Acoustic Sounds. It is kind of pricey, at $15.00 for a 4” x 6” sheet. Acoustic Sounds claims the product works via “Hysteric Damping.” Anyone had any experience with this product?

Cheers,

ceulrich

Thanks for all the suggestions and comments.

I never would have thought of a product made for the automobile industry!

The Mortite Caulking idea is interesting, but I wonder about bonding to the underside of a chassis top panel?

The Butyl deadening material looks interesting, and at 10 sq ft for $27.00 is priced right.

Doing the “Google thing”, I came up with AcousTech’s vibration dampening material sold by Acoustic Sounds. It is kind of pricey, at $15.00 for a 4” x 6” sheet. Acoustic Sounds claims the product works via “Hysteric Damping.” Anyone had any experience with this product?

Cheers,

ceulrich

Mortite Caulking

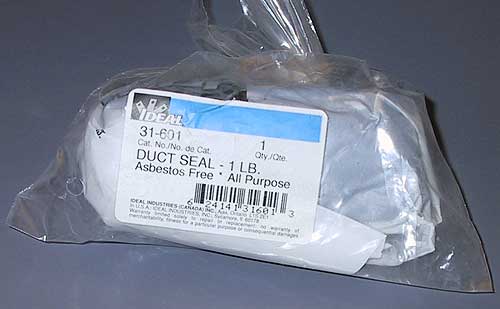

Ductseal works better. By more than a bit. I have tried both. And plasticine, and, and...

https://www.t-linespeakers.org/design/tweeks.html (second bit)

Of course, vibration isolation shoukd nit be overlooked in the quest for ridding vibration, the lowest frequencies are the worst offenders. vibration isolation is a two way street it allows vibration to be shed from the component and reduces low frequency vibration coming up from the floor.

It may sound odd but I am using 3.5mm thick vinyl flooring leftovers. It has surprisingly high density. I also use it to damp inside of spkr cabinets. I secure it with double sided carpet tape.

Hello All – Again

I should have taken some of your advice. As I said previously, I chose to go with the product from Acoustic Sounds – Bad Idea. I bought 4 sheets (2 for each amplifier), one bonded to the underside of the amplifier’s top panel just fine, the other 3 fall off after a few weeks. I did a thorough cleaning of the underside of the panels using 95% isopropyl alcohol before instillation. For the ones that fell off, I tried warming the panels first, and then weighting down the sheets with a gallon-jug of water for a few hours, before reinstalling the top panels back on the amplifiers, no luck, still falls off after a few weeks. It is interesting in that a considerable amount of mastic remains on the panel after the sheet falls off. This says to me that the bond between the panel and mastic is good but, possibly, there is too much mastic on the sheets. For the one sheet that bonded well – I tried to pry it off, it won’t budge.

Cheers,

ceulrich

I should have taken some of your advice. As I said previously, I chose to go with the product from Acoustic Sounds – Bad Idea. I bought 4 sheets (2 for each amplifier), one bonded to the underside of the amplifier’s top panel just fine, the other 3 fall off after a few weeks. I did a thorough cleaning of the underside of the panels using 95% isopropyl alcohol before instillation. For the ones that fell off, I tried warming the panels first, and then weighting down the sheets with a gallon-jug of water for a few hours, before reinstalling the top panels back on the amplifiers, no luck, still falls off after a few weeks. It is interesting in that a considerable amount of mastic remains on the panel after the sheet falls off. This says to me that the bond between the panel and mastic is good but, possibly, there is too much mastic on the sheets. For the one sheet that bonded well – I tried to pry it off, it won’t budge.

Cheers,

ceulrich

Perhaps you should have indicated the internal temperature rise above ambient, and whether you wanted to avoid any kind of retrofit 'fixing' to the panel (ie. to keep external view the same), and given some comment on the 'why is it vibrating' request (eg. it doesn't, but if I knock it then it does vibrate).

I'd suggest fixing almost any 'mat' under the top panel would suppress vibration. Fixing could be as simple as using shoo-goo or silicone rubber. A mat could be as simple as an old 'mouse mat', or some discarded neoprene, or thick cardboard. It may be that the perimeter contact is making the noise, and a strip of double-sided tape along the perimeter where the top panel is screwed would avoid any noise. It may be that if the vibration is reaching the amp from say a speaker, then modifying the 'feet' of the amp to better rubber, or sitting the feet on neoprene, or ... would avoid the amp chassis from vibrating as much.

I'd suggest fixing almost any 'mat' under the top panel would suppress vibration. Fixing could be as simple as using shoo-goo or silicone rubber. A mat could be as simple as an old 'mouse mat', or some discarded neoprene, or thick cardboard. It may be that the perimeter contact is making the noise, and a strip of double-sided tape along the perimeter where the top panel is screwed would avoid any noise. It may be that if the vibration is reaching the amp from say a speaker, then modifying the 'feet' of the amp to better rubber, or sitting the feet on neoprene, or ... would avoid the amp chassis from vibrating as much.

- Home

- Design & Build

- Parts

- Vibration Dampening Material Suggestions