Hidden away at M&M Metals' website, I found this extrusion (MT28600) with quite a large surface area for its weight. That flange looked like an impediment at first, but then it occurred to me that clamping several of them to a base might be how it was intended to be mounted. If they are mounted with the flange butted up to its neighbor, the closeness of the 'interleaved' fins appears meant for forced cooling, like a tunnel or chimney. With them spread apart a little, the gap appeared more suited for natural convection.

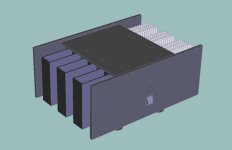

I'm going to let the pics try to speak for themselves and come back later with more comments. The base as shown is 0.25 inch thick, 3 inches wide and 6 inches tall (but could be dimensioned to suit the enclosure and choice of fin spacing). A 6 inch piece of extrusion is shown. Overall length of the extrusion is 4.45 inches. Hardware shown is 10-32.

I'm going to let the pics try to speak for themselves and come back later with more comments. The base as shown is 0.25 inch thick, 3 inches wide and 6 inches tall (but could be dimensioned to suit the enclosure and choice of fin spacing). A 6 inch piece of extrusion is shown. Overall length of the extrusion is 4.45 inches. Hardware shown is 10-32.

Attachments

Last edited:

There's some interference with the hardware (one set of 10-32 SHCS, hex nut, and washers shown) and the closest fin and flange (which would both need to be notched), but otherwise it looks like it might work in practice.

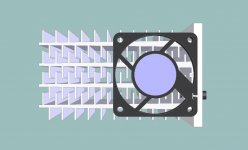

The second pic shows a 60mm square fan, and the last pic is of a 119mm square fan.

The second pic shows a 60mm square fan, and the last pic is of a 119mm square fan.

Attachments

Last edited:

For those with Burning Amp chassis (Pass prototype chassis) that would like more heat sinking, this extrusion fits pretty nicely in the original position between the transistors and triples (3x!) the heat sink surface area.

Attachments

Nar, I have no performance figures for this extrusion. I think an array of these extrusions will have better natural convection if spaced farther apart, so with or without fan is perhaps not a practical comparison....?

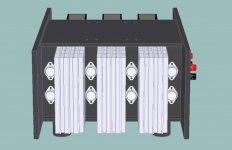

Here's what 12 of these extrusions looks like in the stock BA chassis (spaced ~0.9 inch on center). This spacing 'looks right' for natural convection, and I haven't seen another suitable extrusion with this much surface area per weight.

Twelve is the magic number, as a full extrusion is 6 feet long, so with some material lost to the saw blade, one would get 12 pieces of ~5-7/8 inch tall.

Another apparent advantage is that, depending on the base thickness, this whole hs assy would have a quick warm-up time as it has relatively low mass.

Twelve is the magic number, as a full extrusion is 6 feet long, so with some material lost to the saw blade, one would get 12 pieces of ~5-7/8 inch tall.

Another apparent advantage is that, depending on the base thickness, this whole hs assy would have a quick warm-up time as it has relatively low mass.

Attachments

- Status

- Not open for further replies.