Hello,

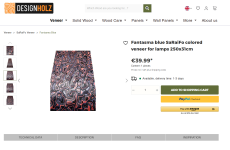

I plan on veneering my first set of speakers once I finish building them. I’ve always painted my previous builds so I have a few questions on veneer finishes. I plan on utilizing this veneer for the front baffle.

Can anyone recommend a nice finish for this veneer to really make it “pop” with a nice sheen to it? I’ve heard of Rubio Monocoat but I’m not sure which one I should be looking at. The rest of the cabinet will be done in Black Ebony.

Thanks in advance!

I plan on veneering my first set of speakers once I finish building them. I’ve always painted my previous builds so I have a few questions on veneer finishes. I plan on utilizing this veneer for the front baffle.

Can anyone recommend a nice finish for this veneer to really make it “pop” with a nice sheen to it? I’ve heard of Rubio Monocoat but I’m not sure which one I should be looking at. The rest of the cabinet will be done in Black Ebony.

Thanks in advance!

If that was a typical veneer, I'd say sure, Rubio would be a nice finish and is easy to apply, although it is expensive for an oil finish. I think Oil Plus 2C is their best seller and what I have used.

But that is not a typical veneer -- what is it?

But that is not a typical veneer -- what is it?

Man that veneer is trippy, love it, I also want to know what it is.

Best advise I ever saw regarding finishing veneer.

To make the grain and pattern really stand out.

Before any coating is applied.

hand sand, then wipe down with lint free cloths and mineral turpentine.

and just keep doing that until the cloths come off clean.

you might be suprised at just how much 'dust' is sucked out of the surface and pores.

i used polyurethane (cant remember the brand now) watered down with turps, repeated the sand and clean between each coat.

something like 20 coats later.....

no idea how to proceed between coats with waxes though.

It was a time consuming pain to do, but the result was absolutely worth it.

Best advise I ever saw regarding finishing veneer.

To make the grain and pattern really stand out.

Before any coating is applied.

hand sand, then wipe down with lint free cloths and mineral turpentine.

and just keep doing that until the cloths come off clean.

you might be suprised at just how much 'dust' is sucked out of the surface and pores.

i used polyurethane (cant remember the brand now) watered down with turps, repeated the sand and clean between each coat.

something like 20 coats later.....

no idea how to proceed between coats with waxes though.

It was a time consuming pain to do, but the result was absolutely worth it.

Those man made veneers do not have any depth to them so whatever finish you use they will be a bit flat looking.

But probably best you are going to get is a satin spray lacquer.Which you can buy in spray cans for small jobs.

But probably best you are going to get is a satin spray lacquer.Which you can buy in spray cans for small jobs.

It's called "SaRaiFo Veneers"

SaRaiFo = Save the RainForest: When you process this veneer, you are helping to relieve some of the pressure on tropical tree populations and thereby protect them. By buying SaRaiFo products, you can do your own personal part! SaRaiFo wood veneers are made from rotary cut veneer of very fast growing wood species (usually ajous, poplar, lime). The veneers are freed from wood defects and glued/compressed/pressed into a solid block in many different optimized production steps, and then sliced into designer veneers of real wood in a special process.

There are tons of options but this particular variant is called "fantasma blue"

SaRaiFo = Save the RainForest: When you process this veneer, you are helping to relieve some of the pressure on tropical tree populations and thereby protect them. By buying SaRaiFo products, you can do your own personal part! SaRaiFo wood veneers are made from rotary cut veneer of very fast growing wood species (usually ajous, poplar, lime). The veneers are freed from wood defects and glued/compressed/pressed into a solid block in many different optimized production steps, and then sliced into designer veneers of real wood in a special process.

There are tons of options but this particular variant is called "fantasma blue"