Hi all,

It's been a while since my last post on diyaudio - mostly due to starting my first year at uni.

I was thinking of designing a battery powered preamp that uses sealed, gel batteries (Yuasa etc), but I can't find a suitable charger on the web.

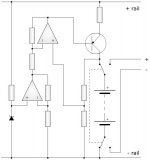

My design is based around a differential amp that varies the base voltage on a transistor by comparing the battery voltage with a reference voltage (the reverse biased zener) and therefore charges at diffferent currents based on the condition of the battery - resistors will be chosen to obey the 1/100th capacity rule once the battery is completely charged.

Will this idea work?

I'm sure there are some serious floors somewhere as most variable rate battery chargers I've seen seem a lot more complex than this.

Thanks for looking - any ideas will be greatfully received

It's been a while since my last post on diyaudio - mostly due to starting my first year at uni.

I was thinking of designing a battery powered preamp that uses sealed, gel batteries (Yuasa etc), but I can't find a suitable charger on the web.

My design is based around a differential amp that varies the base voltage on a transistor by comparing the battery voltage with a reference voltage (the reverse biased zener) and therefore charges at diffferent currents based on the condition of the battery - resistors will be chosen to obey the 1/100th capacity rule once the battery is completely charged.

Will this idea work?

I'm sure there are some serious floors somewhere as most variable rate battery chargers I've seen seem a lot more complex than this.

Thanks for looking - any ideas will be greatfully received

Attachments

Nope, this idea will not work.

Lead-acid batteries very much prefer being charged by a constant voltage, typically 2.3-2.4v per cell. At the end of the charge cycle they can be floated at a slightly lower voltage to keep them happy. It is NiCd/NIMH batteries that must be charged using constant current.

All types have temperature dependency that makes high charging rates much more tricky. This is why automobiles use 2.3v/cell rather than the faster 2.4v/cell - the charging system would have to compensate for battery temperature changes at that point which would require a bit more circuitry than an alternator and some rectifiers!

Lead-acid batteries very much prefer being charged by a constant voltage, typically 2.3-2.4v per cell. At the end of the charge cycle they can be floated at a slightly lower voltage to keep them happy. It is NiCd/NIMH batteries that must be charged using constant current.

All types have temperature dependency that makes high charging rates much more tricky. This is why automobiles use 2.3v/cell rather than the faster 2.4v/cell - the charging system would have to compensate for battery temperature changes at that point which would require a bit more circuitry than an alternator and some rectifiers!

...constructive criticism

Thanks for the feedback - do you have any ideas for a design give that this will not work?

Thanks for the feedback - do you have any ideas for a design give that this will not work?

Refer to the datasheet for the extremely popular, industry standard 3-terminal variable voltage regulator, the LM317 .

Basically, you need to make a 13.8V voltage regulator to charge your Lead-acid battery. There are certainly more sophisticated, and better performing (faster, more accurate, enabling longer battery life, etc.) ways to do this, especially some nice offerings by Maxim, Linear Technology, etc., but I think it is best to start with something simple that works and then progress from there otherwise you'll never know whether all of the extra effort (and expense!) was worth it.

Basically, you need to make a 13.8V voltage regulator to charge your Lead-acid battery. There are certainly more sophisticated, and better performing (faster, more accurate, enabling longer battery life, etc.) ways to do this, especially some nice offerings by Maxim, Linear Technology, etc., but I think it is best to start with something simple that works and then progress from there otherwise you'll never know whether all of the extra effort (and expense!) was worth it.

check out these sites

Texas Instruments (eee.ti.com) must have a dozen battery charger chips, so does Maxim. In particular you want to read the "whys and wherefores" of lead acid chargers on the TI site.

Texas Instruments (eee.ti.com) must have a dozen battery charger chips, so does Maxim. In particular you want to read the "whys and wherefores" of lead acid chargers on the TI site.

Charging a lead-acid at constant voltage will work, and is easy, but it is relatively slow.

Check out this for both background on charging lead-acid cells, and information on TI's chip. I built a charger using this and it worked fine.

http://focus.ti.com/lit/an/slua115/slua115.pdf

Check out this for both background on charging lead-acid cells, and information on TI's chip. I built a charger using this and it worked fine.

http://focus.ti.com/lit/an/slua115/slua115.pdf

- Status

- Not open for further replies.