Yeah, the notches occur at the same freqs (900, 1.8k, 2.7k...) for most of the measurements, so they're somewhat setup-related. I recall starting out with spkr & mic closer to the board (1M) but having to move them further away in order to get the needed rejection from the direct sound and keeping the filter bandwidth wide enough for low-freq extension. I probably should have used a more-directional microphone...It's interesting to compare those reflection notches.

I would appreciate a brief summary of your conclusions, jbau.

My conclusions are pretty much as stated earlier. Material properties matter most at smaller wavelengths (higher freqs). Thickness + density matter most at low freqs. There's no such thing as a thin low-freq absorber. The felt is very good above 2.5kHz, but almost invisible at 1.3kHz!

I used the dense green cotton sheeting (automotive absorber without the fire-retardant treatment) to line the walls of ported enclosures, the upholstery cotton for filling sealed boxes, and the felt for baffle dampening. On an "absorption vs cost" basis, the cotton sheeting is probably the overall winner. It's also a very good thermal insulator.

Last edited:

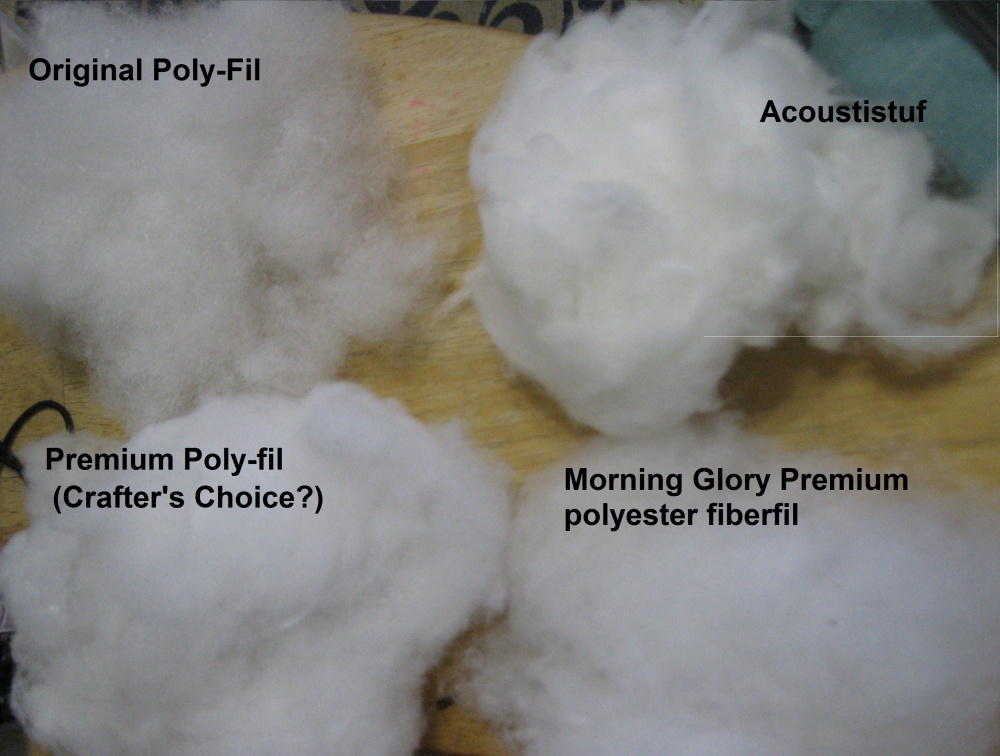

Apparently there are 2 forms of 'Premium' Polyfil then. That is the consistency I do not care for unless using in completely-stuffed vented boxes or for aperiodic purposes. Look for a whiter-color in Poly-Fil brand. Avoid the Ultra-loft and siliconized coated stuff.

I have used the Crafter's Choice Poly-Fil and liked it, and it's more similar to Acousti-Stuf as there are crimpings in it. I'm certain there is a whiter Premium Poly-fil that is not the 'original' stuff. If you want to avoid the possible inferior Poly-Fil brand stuff, just get the Morning Glory brand. Just don't get the 'Cluster Stuff'.

Last edited by a moderator:

If possible, a technical description of the fiber (in deniers / mm.), chopped length, twisted / crimped / oriented/ otherwise textured, material, and wall thickness would be informative for those of us where such material is available, but not those brands.

Acrylic fiber is used here for machine washable blankets, and also added to wool used for sweaters.

Polyester, viscose and other materials are used in fabrics.

So such a description might help.

Acrylic fiber is used here for machine washable blankets, and also added to wool used for sweaters.

Polyester, viscose and other materials are used in fabrics.

So such a description might help.

A trick I learned from the car audio crowd was that the mold prone deadening materials can be sealed inside a thin membrane to mitigate moisture problems.

Common, disposable painting drop cloth material is perfect, sealed with packing tape.

Myself, I still won’t use either materials that pick up mold indoors, or enclose the closed cell foam or bubble wrap in my car doors.

Common, disposable painting drop cloth material is perfect, sealed with packing tape.

Myself, I still won’t use either materials that pick up mold indoors, or enclose the closed cell foam or bubble wrap in my car doors.

Several years ago the best deal I could find on Polyester fiber fill was a deal Costco had on pairs of pillows. After listening for a couple of months I realized things weren't quite right. So I splurged on Nylon Acoustistuff. Aside from the expense, the biggest pain was separating the strands and fluffing the fibers. It was worth it though. I'd like to try the recycled denim but I can't find it anywhere around here.

- Home

- Design & Build

- Parts

- Useful for speaker cabinet fill?