Hi

Today I opend up two Radian 750Pb 2" compresson drivers

The s/n where close, and it seems to be the original diaphragms

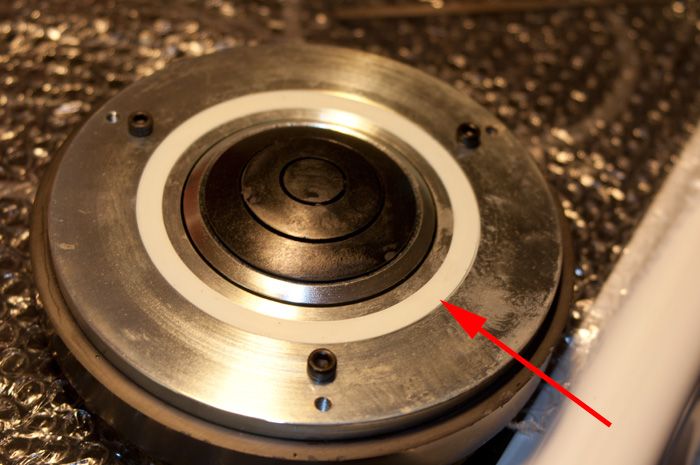

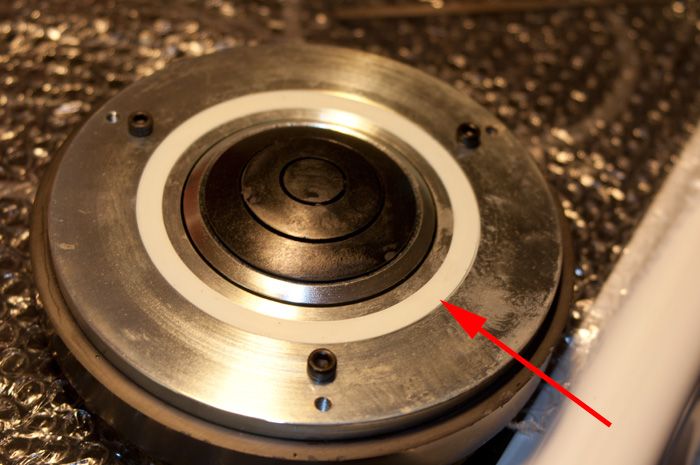

However, in one of them there was a white 0,5 mm thich plastic shim washer (see pix) between the diaphragm and the phase-plug, but not on the other

Is the advice to order a second washer so both drivers are the same, or to leave both drivers without washers?

Brgds

Pix

Sweden

Today I opend up two Radian 750Pb 2" compresson drivers

The s/n where close, and it seems to be the original diaphragms

However, in one of them there was a white 0,5 mm thich plastic shim washer (see pix) between the diaphragm and the phase-plug, but not on the other

Is the advice to order a second washer so both drivers are the same, or to leave both drivers without washers?

Brgds

Pix

Sweden

I have seen this washer / added height as a trick to improve the low end of a compression driver. On a German forum somewhere... Anyway, both drivers should be the same imho with or without washer.

Last edited:

I would advise careful measurement of the two diaphragms to determine whether the shim is compensating for the distance from the diaphragm to the phase plug.

I definitely would advise against removing the shim (diaphragms hitting the phase plug sound really bad :^) ), but would not automatically assume the other needs one.

I definitely would advise against removing the shim (diaphragms hitting the phase plug sound really bad :^) ), but would not automatically assume the other needs one.

Having said that, Radian has said that they put the shim washers in to extend the LF ability of the driver. It is possible that one driver was shimmed for this service and the other not.

Or as noted, it was put in to put the VC centered...

Best to check carefully to see what is up...

_-_-

Or as noted, it was put in to put the VC centered...

Best to check carefully to see what is up...

_-_-

Is there any optimal diaphragm-phaseplug distance for low wattage domestic hifi-use?

What distance is required for a 300Hz (12dB/oct) x-over

What distance is required for a 300Hz (12dB/oct) x-over

I don't know that much about horns, but what i am learning would indicate that there would be a new problem when you solve one. More experienced forum members can probably tell you what happens with Hf extension when the distance to the phaseplug is increased for more x-max. My guess would be less high frequency extension.

Do you have a way to measure the response of the drivers? Would be interesting to see if they are different.

FWIW, I've had to shim some old JBL and Fane bullet tweeters because the replacement frams didn't sit quite right. The original fram edges were a bit thicker. 2 or 3 layers of masking tape did the trick.

FWIW, I've had to shim some old JBL and Fane bullet tweeters because the replacement frams didn't sit quite right. The original fram edges were a bit thicker. 2 or 3 layers of masking tape did the trick.

masking tape

Sacrebleu!

You know very well, the only acceptable material is duct tape. 🙂

RG

Au contraire, mon frere. In this case masking tape is just the ticket. Not as think or as soft as duct tape. I used the traditional color, too - not the blue.

Being a card carrying member of the Possum Lodge I do know that "Duct Tape is the handyman's secret weapon."

Being a card carrying member of the Possum Lodge I do know that "Duct Tape is the handyman's secret weapon."

Drivers are usually designed for the expected excursion with a given horn type and crossover slope, the optimal distance from diaphragm to phase plug varies with design. The distance is not often specified, my guess is from <1mm to as much as 3mm.Is there any optimal diaphragm-phaseplug distance for low wattage domestic hifi-use?

What distance is required for a 300Hz (12dB/oct) x-over

Shimming a diaphragm will increase excursion potential, but will reduce compression ratio and sensitivity, and if the shimming results in the voice coil no longer centered in the gap, high frequency response will be reduced, and more distortion at low frequencies could be expected.

Larger diaphragms require less excursion to achieve the same low frequency output, but 300 Hz is quite low for most horns typically used for "domestic hi fi-use".

There are examples of very large and long horns like the Sato, which using "PA" drivers to give plenty of output for domestic use as low as 120-200 Hz, but the Fs of most "hi fi" 1" exit drivers make 400 Hz more of a practical limit.

Many 3" and 4" diaphragm can hit levels at 300 Hz (on the right horn) without excessive distortion/excursion, adequate for most domiciles.

That reminds me I have to renew my membership.Being a card carrying member of the Possum Lodge

Thanks,

RG

Read this: http://www.eighteensound.com/staticContent/download/pdf/18Sound_diaphragm_procedure.pdf illustrations 6 to 8

I understand that provided your drivers have original factory-mounter diaphs, the washer was probably placed on purpose to achieve the optimum distance (thus compensating inevitable manufacturing tolerances), as Weltersys points out.

BTW: the paper linked above refers to a standard distance of 0.8 mm +/- 0.05mm...🙂

I understand that provided your drivers have original factory-mounter diaphs, the washer was probably placed on purpose to achieve the optimum distance (thus compensating inevitable manufacturing tolerances), as Weltersys points out.

BTW: the paper linked above refers to a standard distance of 0.8 mm +/- 0.05mm...🙂

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Use shim washer, or not? diaphragm closer to phaseplug in Radian compression driver