The Jantzen wires are very neatly wound@Bmsluite , what's your reference for an aesthetically pleasing solid wire air core inductor? just curious

The Jantzen wires are very neatly wound@Bmsluite , what's your reference for an aesthetically pleasing solid wire air core inductor? just curious

Got it. I figured my test wasn't accurate with how far it was offOfficial data on inductor dcr are accurate, and you can't rely on dcr values measured with LCR meter.

Basic multimeter will confirm it. 1mH coil has about 24m of 16 awg wire. 1 m reads 0.013R.

I have a couple of iron core coils from Madisound with the same type of mounting. I affix those directly to the cabinet walls since the 35 mH parts are a hefty chunk of metal which would rip through a circuit board with a moderate impact, and the values seemed to be off by about +10% to +12%. It turned out the #8 alloy steel screws protruding about an inch (2.5 cm) from the end of the iron core were enough to significantly increase the inductance. A switch to stainless steel screws fixed the problem.

Hi,The Jantzen wires are very neatly wound

Got it. I figured my test wasn't accurate with how far it was off

For DCR, you can use the 4-wire method. Just inject a known current (1A to produce good voltage on small resistance) and measure the voltage across the inductor. For the current source, you can use a voltage power supply with a resistor in series. E.g.: 10V and 10ohms to get 1A.

At the bottom of this page, Troels has a link for how to measure low-DCR coils using capacitors to target specific freq range for the test. http://www.troelsgravesen.dk/coils.htm

I think you'd be surprised how much cutting little corners adds up. A little half *** there, a little more "who cares" over there, some "what difference does it make" on this aspect of the build, etc.Yes... A tenth of a dB response change could destroy an otherwise good x-over!

That's how you end up with a frequency response and a system that measures and sounds totally different from how you expected.

What I just posted is good research. Keep ferrous materials out of those holes.

I agree. In addition, the laminated steel used in inductors/transformer has special properties for that purpose (AC mag flux).What I just posted is good research. Keep ferrous materials out of those holes.

The screw, although it also increases the inductance, is not made of proper material for being under an AC magnetic flux.

I am super curious about whether that is a constant inductance increase across frequencies, or is variable. Is it the same increase at 50hz, 300Hz, and 1000Hz ? I suspect it may be different, which opens up a whole new issue (just like freq variable DCR in an electrolytic cap).The screw, although it also increases the inductance, is not made of proper material for being under an AC magnetic flux

Hi,I am super curious about whether that is a constant inductance increase across frequencies, or is variable. Is it the same increase at 50hz, 300Hz, and 1000Hz ? I suspect it may be different, which opens up a whole new issue (just like freq variable DCR in an electrolytic cap).

Good question, I can't tell you before researching a bit more.

What I know is those holes in the iron core increase air gap (less permeability, lower inductance) and also more resistance to Eddy currents (less losses).

Filling those with ferromagnetic material (screw) not designed for this purpose, does increase permeability but may lead to distortion.

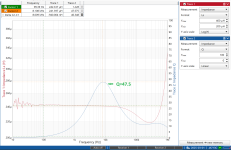

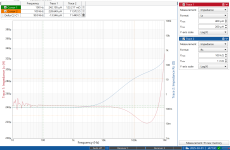

Sometime ago, I came across a similar issue and I posted here in this forum to get help.

In that case, I had built an E-I iron core with gap and it worked fine.

But when I closed the EI core with an ordinary iron bracket, just for easy installation, I've got significant 3rd harmonic distortion.

I posted the FFT scope screens. Here's the post:

Ferrite E-cores with gaps have the gap in the centre pole which keeps it away from any nearby metal. And since they use two E cores together you can have single or double gap by using one or two gapped pieces in the stack.

I'm using tie wraps but I did test brass screws VS stainless. Stainless still affects it quite a lot. Brass has basically no effect static, however, if you start playing music it then DOES have an effect as well.Obviously being within hailing distance of an inductor core matters, but I generally order stainless steel with more non-ferrous metals in the alloy for fasteners in my audio gear (with standoffs, barrier strips, etc.) A bit more expensive but not bad.

Skip

I forget what this phenomena is called but brass has an effect when a magnetic field becomes present.

It's variable. I tested that.I am super curious about whether that is a constant inductance increase across frequencies, or is variable. Is it the same increase at 50hz, 300Hz, and 1000Hz ? I suspect it may be different, which opens up a whole new issue (just like freq variable DCR in an electrolytic cap).

Also, I tested different orientations of inductors while playing music. Something I have never seen done.

When you test them with a single tone running through all the rules of thumb apply.

However, when you start playing music a lot changes.

What I found is DO NOT have them in the same plane. I needed to move the inductors over 5 inches apart in order for them not to affect one another while playing music. Putting them in different planes, even if you can see one inductor through another, is way better.

If I can figure out how to upload a YouTube video I'll show this test. It's definitely not what I suspected. Dynamic music affects the magnetic fields so much more than a singular sine wave

- Home

- Loudspeakers

- Multi-Way

- US Coils Inductor Review