Hi,

I have an old amp where the bias voltage is unstable for the right channel. Left channel is stable. Manufacturer recommends 4mv to set for the quiescent current when adjusting using RV1 pot. However the right channel voltage will fluctuate up and down rapidly when measured with a multimeter. Sometimes it goes to 0mV and stays there for a few minutes.

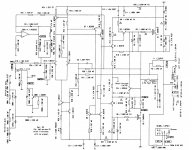

Attached is the schematic of this amplifier for 1 channel. Can I have assistance on where is the problem? Which component is faulty which causes the bias voltage to fluctuate up and down quite rapidly?

I have an old amp where the bias voltage is unstable for the right channel. Left channel is stable. Manufacturer recommends 4mv to set for the quiescent current when adjusting using RV1 pot. However the right channel voltage will fluctuate up and down rapidly when measured with a multimeter. Sometimes it goes to 0mV and stays there for a few minutes.

Attached is the schematic of this amplifier for 1 channel. Can I have assistance on where is the problem? Which component is faulty which causes the bias voltage to fluctuate up and down quite rapidly?

Attachments

Last edited:

I have an old amp where the bias voltage is unstable for the right channel.

The pot itself may be bad.

The pot itself may be bad.

How do I know if the pot is bad? I’ve meanaged to take out the pot and measured the resistance across and resistance seem to be stable n not fluctuating. Hence what else could be faulty?

as a man said,sounds like a potentiometer has dirty contacts wich may make some problems with higher current flowing through it,than it is a current from your Ohm-meter. also,it could be poor soldier somewhere at pcb wich is not easy to see. potentiometer is not expensive, buy one with same resistance but closed type, like multiturn one.

How do I know if the pot is bad? I’ve meanaged to take out the pot and measured

the resistance across and resistance seem to be stable n not fluctuating.

Hence what else could be faulty

Poor wiper contact, dirt, wear, oxidation. The reading between the ends

of the element could still be fine. Probably it's not even sealed.

I would just replace it regardless, it's considered to be routine maintenance.

This is a critical part, and is not expensive.

Last edited:

testing a pot for continuity is one thing but ensuring it's mechanically stable is another, try using clipleads and then tap the pot, if the resistance changes it's mechanically intermittent, i've been lead astray checking continuity failing to realize that the pressure i was applying with test leads has closing bad pressings on the outer terminals, same for the wiper.

with the bias is fluctuating i'd be monitoring the B+ lines for noise or be sniffing out caps.

with the bias is fluctuating i'd be monitoring the B+ lines for noise or be sniffing out caps.

Last edited:

I was thinking caps as well, any tantalum caps on this board?

Another routine maintenance replacement

Another routine maintenance replacement

i won't advise replacing a component as a "routine maintenance" procedure and have seen that sort of practice create problems.

the other thing i would do is visually inspect all solder joints for intermittents, the tap test applies here as well if the fluctuations get worse or stops there's a funky solder joint.

the other thing i would do is visually inspect all solder joints for intermittents, the tap test applies here as well if the fluctuations get worse or stops there's a funky solder joint.

Last edited:

I don't see any. Mostly polyester, film and ceramic.I was thinking caps as well, any tantalum caps on this board?

Another routine maintenance replacement

I've checked the solder points and tapped all components. Now the multimeter is showing 0volts. It's weird really. Why is there no current flowing thru? I adjusted the bias pots from min to max, still showing zero.i won't advise replacing a component as a "routine maintenance" procedure and have seen that sort of practice create problems.

the other thing i would do is visually inspect all solder joints for intermittents, the tap test applies here as well if the fluctuations get worse or stops there's a funky solder joint.

Anyway I've ordered a new pot which turn 26 times with screw driver for the replacement. Ordered it from element14.com.

Once I install it I will report back on the results.

I've ordered a new pot. Will report the results once I have installed it.testing a pot for continuity is one thing but ensuring it's mechanically stable is another, try using clipleads and then tap the pot, if the resistance changes it's mechanically intermittent, i've been lead astray checking continuity failing to realize that the pressure i was applying with test leads has closing bad pressings on the outer terminals, same for the wiper.

with the bias is fluctuating i'd be monitoring the B+ lines for noise or be sniffing out caps.

Yes I am doing just thatPoor wiper contact, dirt, wear, oxidation. The reading between the ends

of the element could still be fine. Probably it's not even sealed.

I would just replace it regardless, it's considered to be routine maintenance.

This is a critical part, and is not expensive.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Unstable Bias voltage