@ Eworkshop1708

Point of the forum is learning ....replacing all parts to stop the problem is a bad procedure plus that you will never learn where was the problem at the first place .

The twin diode placed on the heatsink cannot be replaced the way you did it Not any diode can be placed there , There is a bunch of issues related to the behavior of this "thermal tracking " diode Not to mention extended threads on what might be a close replacement rather than anything available ..

yet again replacing drivers and Vas with what ????? again anything available ??? 1500xx series are rugged devices but not drop in replacements .

Your amplifier will never be the same which is a statement that includes both sound and stability issues.

There is a difference between a working amplifier and an amplifier that is stable and sounds superb ,,,all of it is just a question of targeting ...

regards

Sakis

Point of the forum is learning ....replacing all parts to stop the problem is a bad procedure plus that you will never learn where was the problem at the first place .

The twin diode placed on the heatsink cannot be replaced the way you did it Not any diode can be placed there , There is a bunch of issues related to the behavior of this "thermal tracking " diode Not to mention extended threads on what might be a close replacement rather than anything available ..

yet again replacing drivers and Vas with what ????? again anything available ??? 1500xx series are rugged devices but not drop in replacements .

Your amplifier will never be the same which is a statement that includes both sound and stability issues.

There is a difference between a working amplifier and an amplifier that is stable and sounds superb ,,,all of it is just a question of targeting ...

regards

Sakis

The point of upgrading is so that it WILL NOT be the same, but better!

That is like saying upgrading my CPU....your computer will never be the same, there is a difference between a working computer and a fast one...........

See how silly that sounds?

I'm not trying to give you a hard time, sakis, but if you have discovered the problem, and upgraded to better parts, what the harm in that?

That is like saying upgrading my CPU....your computer will never be the same, there is a difference between a working computer and a fast one...........

See how silly that sounds?

I'm not trying to give you a hard time, sakis, but if you have discovered the problem, and upgraded to better parts, what the harm in that?

Last edited:

SUCCESS!!!!

The BIAS is ROCK SOLID STABLE!!!!

Besides changing 2SA916 to 2SA1837, I also changed D502A to a standard glass silicone diode that I measured the voltage drop to be almost exactly the same as the B-E junction of 2SA1837, and have it touching the transistor. The BIAS does not drift as much as it used to when warming up after changing that diode!

I'm about to change everything in the other channel the same way now that it is working. Changing the drivers did help with thermal drift as well even though they were not failed.

The BIAS is ROCK SOLID STABLE!!!!

Besides changing 2SA916 to 2SA1837, I also changed D502A to a standard glass silicone diode that I measured the voltage drop to be almost exactly the same as the B-E junction of 2SA1837, and have it touching the transistor. The BIAS does not drift as much as it used to when warming up after changing that diode!

I'm about to change everything in the other channel the same way now that it is working. Changing the drivers did help with thermal drift as well even though they were not failed.

Attachments

you are unbelievably wrong ...again

The diode and the way you implemented it will create stability issues compared to what you had before ..Though probably you will never find this out unless you push the amp But don't count on this and you might find out the stability issues far before that .

MJ 150xx drivers are only better in how rugged they are their sound performance is far worst than the original transistors ...You see at the time they had the ability to make really nice semis but stability was always an issue .

Silly? i don't think so , because when you upgrade a CPU you aim to better processing speed and more functions In amplifiers this is not important .In amplifiers quality is what matters , then stability and then repairs and changes to be made should be at least equal to the original if not better

So if your choice was this diode string and the replacement of the drivers was from the 150xx series you lost stability and proper thermal compensation, especially from the 1N4007 in series , you made the amp sound worst But yes your drivers will be the last thing to fail when the amp fails totally some time in the feature .

Yet again replacing random parts is not a solution ...This is electronics for 13 year odl kid ...This is the things we did at that era when we didn't have knowledge enough to locate the problem

Explanation in details

In the first place both of these diodes should be in contact with the heatsink , secondly the behavior of the original diode in compensation and speed of reaction is different than your choice ..there will be a chance of either over biasing or under biasing (overcompensation) that might produce crossover distortion or thermal runaway at a given rated power and a given operating temperature .

A better solution could be to create a classic Vbe multiplier around a BD139 compare operating conditions with the working ch and given amounts of temperature and power and replace alike for both CH .

Your words about the drivers :

I just looked up the datasheet on the drivers. 2SA985/2275

They are only rated to 120V, and the amp has over ~55V rails unloaded. This may be unrelated to the issue, but I had to mention it. Again, only issue I have is with LEFT channel, but boy the drivers run hot for both channels.

That is also wrong ..Japanese like to push hard the drivers and in general operate the transistors in limits like the above. IE operate a small TO92 transistor that is 30V rated with 29.9 volts regulated . In this style transistor will operate only 30-40 years long and trust me on that it will play far better than a 50V device ..Japanese was simply MASTERS in proper semis choosing and since they had the feedback next door learned how to squeeze the best of the given semis .

When it comes to drivers often ppl make the mistake to look at the "important " ratings which is voltage of operation , available current and total W of the semi ...

Well for your information there is more parameters except the above and the previous mention about operating voltage that are very critical

MJ150xx is 120 volt device so in this case yes you can supply it closer to the operating point

Though are you sure that the previous stages can drive these transistors easily since those are 8A and 50W devices and probably present a very nice capacitance as a load to previous stages ? In this case a scope or spectrum analyzer will show both that previous stages might not be able to drive those transistors properly and for 100% sure that compensation for this circuit will need many changes . Original drivers was only 20something pf i expect the 150xx to be far more .

Then 150XX drivers are only 30MHZ devices while the original was only 180MHZ devices ...So your driver choice on its own is a huge degrade for this amplifier ...

Are we done ?

The diode and the way you implemented it will create stability issues compared to what you had before ..Though probably you will never find this out unless you push the amp But don't count on this and you might find out the stability issues far before that .

MJ 150xx drivers are only better in how rugged they are their sound performance is far worst than the original transistors ...You see at the time they had the ability to make really nice semis but stability was always an issue .

Silly? i don't think so , because when you upgrade a CPU you aim to better processing speed and more functions In amplifiers this is not important .In amplifiers quality is what matters , then stability and then repairs and changes to be made should be at least equal to the original if not better

So if your choice was this diode string and the replacement of the drivers was from the 150xx series you lost stability and proper thermal compensation, especially from the 1N4007 in series , you made the amp sound worst But yes your drivers will be the last thing to fail when the amp fails totally some time in the feature .

Yet again replacing random parts is not a solution ...This is electronics for 13 year odl kid ...This is the things we did at that era when we didn't have knowledge enough to locate the problem

Explanation in details

In the first place both of these diodes should be in contact with the heatsink , secondly the behavior of the original diode in compensation and speed of reaction is different than your choice ..there will be a chance of either over biasing or under biasing (overcompensation) that might produce crossover distortion or thermal runaway at a given rated power and a given operating temperature .

A better solution could be to create a classic Vbe multiplier around a BD139 compare operating conditions with the working ch and given amounts of temperature and power and replace alike for both CH .

Your words about the drivers :

I just looked up the datasheet on the drivers. 2SA985/2275

They are only rated to 120V, and the amp has over ~55V rails unloaded. This may be unrelated to the issue, but I had to mention it. Again, only issue I have is with LEFT channel, but boy the drivers run hot for both channels.

That is also wrong ..Japanese like to push hard the drivers and in general operate the transistors in limits like the above. IE operate a small TO92 transistor that is 30V rated with 29.9 volts regulated . In this style transistor will operate only 30-40 years long and trust me on that it will play far better than a 50V device ..Japanese was simply MASTERS in proper semis choosing and since they had the feedback next door learned how to squeeze the best of the given semis .

When it comes to drivers often ppl make the mistake to look at the "important " ratings which is voltage of operation , available current and total W of the semi ...

Well for your information there is more parameters except the above and the previous mention about operating voltage that are very critical

MJ150xx is 120 volt device so in this case yes you can supply it closer to the operating point

Though are you sure that the previous stages can drive these transistors easily since those are 8A and 50W devices and probably present a very nice capacitance as a load to previous stages ? In this case a scope or spectrum analyzer will show both that previous stages might not be able to drive those transistors properly and for 100% sure that compensation for this circuit will need many changes . Original drivers was only 20something pf i expect the 150xx to be far more .

Then 150XX drivers are only 30MHZ devices while the original was only 180MHZ devices ...So your driver choice on its own is a huge degrade for this amplifier ...

Are we done ?

Last edited:

Having the bias stable in static conditions is 10% of the job

To achieve equal performance in the amplifier ( or better ) the graph of thermal compensation should be the same or better than it was before obviously at any power rating and at any operation temperature with in the given specs of the amplifier .

To achieve equal performance in the amplifier ( or better ) the graph of thermal compensation should be the same or better than it was before obviously at any power rating and at any operation temperature with in the given specs of the amplifier .

You are correct about the FT difference between original drivers and replacements. However, I NEVER used "random" parts to replace these. These are complementary pairs I have been using in other amplifiers. Countless people here at DIYAUDIO use these same transistors I used, and even APEX uses 2SA1837/2SC4793 and 15030/31 without issue. You did mention that transistors can thermally fatigue, and I suspected these drivers, because I would "blow" on them, and the bias would drop significantly, but not with the 15030/31. I could go order some higher FT transistors, but I doubt the customer would hear the difference.

Being the BIAS is super stable now, I can switch back the drivers to the NEC parts

I soldered the 1N4001 to the leg of the TO-220 diode to thermally couple it as best as I could without ordering exotic hard to get parts for this old amp. It seems to be ok, and I am testing it now. If you are right, I will own up to it, but this diode pair seems to be working well.

Please try not to relate to age, I am far from being young, and I have yet to see any "13 year old" working on amplifiers, especially class AB.

This is not a battle, and we are cool, we have both been here at DIYAUDIO long time, and it is ok to disagree, but lets be cool please. It's all good.

ANYONE VOTE TO PUT THE OLD DRIVERS BACK IN????? Please respond.

Being the BIAS is super stable now, I can switch back the drivers to the NEC parts

I soldered the 1N4001 to the leg of the TO-220 diode to thermally couple it as best as I could without ordering exotic hard to get parts for this old amp. It seems to be ok, and I am testing it now. If you are right, I will own up to it, but this diode pair seems to be working well.

Please try not to relate to age, I am far from being young, and I have yet to see any "13 year old" working on amplifiers, especially class AB.

This is not a battle, and we are cool, we have both been here at DIYAUDIO long time, and it is ok to disagree, but lets be cool please. It's all good.

ANYONE VOTE TO PUT THE OLD DRIVERS BACK IN????? Please respond.

Last edited:

Sorry i don't work like that

your excuses sound horrible

obviously 150XX are very nice drivers and 30MHZ of ft is a very fine tool to have in such a rugged device though you built the circuit around them and generally those type of semis are used in high power amplifiers ( properly compensated ) where ft is far more guarded than is in hifi amplifiers .Again except positive comments there is plenty of negative that has to do with the way these semis sound world wide .

I am cool as you said but i was just wondering how much time you consumed to do all this next to the time that could take a proper fault finding which in your case is simply swapping no more than 3-4 parts from the working ch .

You was given the advice to use freeze spray to locate the issue and also explained exactly how this fails and how it operates Got no results from that...Instead you started to replace transistors ...

The excuse "I doubt the customer would hear the difference." sucks and you will be very surprised to listen what the user thinks about that ...Often people that do not grab your attention as expirienced listeners have a far more str8 and clean opinion than audiophiles or audiphools ...Any way this is your call and a question of targeting ..I expect that you have set the targets of your work ....

No ..as said this is not a battle and obviously involves nothing personal This is simply my personal opinion about the procedure and the dangers involved with this line of work ....

Kindest regards

Sakis

PS you wana see 13 kid repairing amplifiers ? travel 37 years back and meet me at my work in Athens ....😀

your excuses sound horrible

obviously 150XX are very nice drivers and 30MHZ of ft is a very fine tool to have in such a rugged device though you built the circuit around them and generally those type of semis are used in high power amplifiers ( properly compensated ) where ft is far more guarded than is in hifi amplifiers .Again except positive comments there is plenty of negative that has to do with the way these semis sound world wide .

I am cool as you said but i was just wondering how much time you consumed to do all this next to the time that could take a proper fault finding which in your case is simply swapping no more than 3-4 parts from the working ch .

You was given the advice to use freeze spray to locate the issue and also explained exactly how this fails and how it operates Got no results from that...Instead you started to replace transistors ...

The excuse "I doubt the customer would hear the difference." sucks and you will be very surprised to listen what the user thinks about that ...Often people that do not grab your attention as expirienced listeners have a far more str8 and clean opinion than audiophiles or audiphools ...Any way this is your call and a question of targeting ..I expect that you have set the targets of your work ....

No ..as said this is not a battle and obviously involves nothing personal This is simply my personal opinion about the procedure and the dangers involved with this line of work ....

Kindest regards

Sakis

PS you wana see 13 kid repairing amplifiers ? travel 37 years back and meet me at my work in Athens ....😀

Last edited:

On more thing ....

""Random parts"" have absolutely nothing with if the drivers you used are complementary ...

It has to do with the "random " procedure which is when a problem exists in the bias replace the Vbe multiplier , the drivers , the Vas, the current source, and all the resistors in the area and will be automatically fixed ...

well yes i ve done that when i was 13 Now days i prefer to find out exactly what is wrong and farther from that find out what caused it and make sure that it will never happen again ...

""Random parts"" have absolutely nothing with if the drivers you used are complementary ...

It has to do with the "random " procedure which is when a problem exists in the bias replace the Vbe multiplier , the drivers , the Vas, the current source, and all the resistors in the area and will be automatically fixed ...

well yes i ve done that when i was 13 Now days i prefer to find out exactly what is wrong and farther from that find out what caused it and make sure that it will never happen again ...

Last edited:

I'm doing some stress testing, 2 ohms load at full volume, four 8 ohms speakers in parallel, lets see how well this thing holds up.............HEHEHE These Onsemi's are brutes, the heatsink is only slightly hot.

Amp is rated for 4 ohms......

Amp is rated for 4 ohms......

Last edited:

A scope will tell you a million more things next to 2ohms testings ...

I think we will continue all night .....

Cool ( or fairly warm) heat sinks at full power into 2ohm load in an amplifier that operates in class AB doesn't mean brute drivers it means that the bias at full power is lower than is supposed to be ...overcompensation in a few words .

Also bandwidth , slew rate harmonics and distortion is what you looking for not ability of driving 2ohms load

Dummy load ( resistive ) with a 2.2uf in parallel is the test you need to do in square wave ....

I think we will continue all night .....

Cool ( or fairly warm) heat sinks at full power into 2ohm load in an amplifier that operates in class AB doesn't mean brute drivers it means that the bias at full power is lower than is supposed to be ...overcompensation in a few words .

Also bandwidth , slew rate harmonics and distortion is what you looking for not ability of driving 2ohms load

Dummy load ( resistive ) with a 2.2uf in parallel is the test you need to do in square wave ....

Last edited:

I now have the heatsink so hot that it's hard to hold my hand on it, the output transistors are hot enough to barely keep my finger on them. The mV across the 0.5ohms emitter resistors rises to 74mV when hot, then starts going down when I idle it again, back to 33mV as the temp goes back down.

So far, so good.....

So far, so good.....

Last edited:

The bias is holding clean, it is not fluctuating when idle, although the other (right) channel I haven't changed varies between 30-42mV when cold, but does not overheat, so I'm convinced that after I change the parts in that channel, it should hold more stable too.

BTW, both bias pots were changed, just to remind you folks. The old pots were junk.

Anyone else input what would they do?

Would you keep the original drivers?

Would you use different diodes? (1N4002 X2 was recommended, I used 1N4001+FMNG12)

Would you have used different output devices?

Would you have tried to order all original replacements, or changed to more modern and common parts?

Would you have done this completely different?

All input is recommended!

BTW, both bias pots were changed, just to remind you folks. The old pots were junk.

Anyone else input what would they do?

Would you keep the original drivers?

Would you use different diodes? (1N4002 X2 was recommended, I used 1N4001+FMNG12)

Would you have used different output devices?

Would you have tried to order all original replacements, or changed to more modern and common parts?

Would you have done this completely different?

All input is recommended!

Hello Guys .. glad you both kept your cool, at one point I thought the thread was going to escalate in a real world argument.

Anyway DIY is for fun and making friends and we can all learn on the way, all different members have different skill levels and experience.

enjoyed reading the thread though

Anyway DIY is for fun and making friends and we can all learn on the way, all different members have different skill levels and experience.

enjoyed reading the thread though

Hello .. yes you are correct, my mistake 🙂

Just checked out your web site .. very impressed 😀

Just checked out your web site .. very impressed 😀

Last edited:

Would you keep the original drivers?.

yes if those was working and have no reputation of going open

Would you use different diodes? (1N4002 X2 was recommended, I used 1N4001+FMNG12)

As said i could go for a BD139 based vbe multiplier

Would you have used different output devices?

No if the originals was working, 999% of the outputs can go shorted if faulty but hardly ever go open so its an on off thing if working then OK

Would you have tried to order all original replacements, or changed to more modern and common parts?

Yes and yes as close to the originals

Would you have done this completely different?

No choices there if you like to stay close in specs and avoid unknown issues like compensation, drifts, and so on your choices are limited

yes if those was working and have no reputation of going open

Would you use different diodes? (1N4002 X2 was recommended, I used 1N4001+FMNG12)

As said i could go for a BD139 based vbe multiplier

Would you have used different output devices?

No if the originals was working, 999% of the outputs can go shorted if faulty but hardly ever go open so its an on off thing if working then OK

Would you have tried to order all original replacements, or changed to more modern and common parts?

Yes and yes as close to the originals

Would you have done this completely different?

No choices there if you like to stay close in specs and avoid unknown issues like compensation, drifts, and so on your choices are limited

If I were you I would install the original driver transistors. It was obvious at the get-go that they were just fine (if not, your complaint would have been quite different!!).

I would not be surprised to find that the original output devices are OK too, however intense heat cycling isn't good for power transistors in general. If this problem has only been going on a short while then its likely no worries to re-install the original outputs.

Glad you got it sorted!

I would not be surprised to find that the original output devices are OK too, however intense heat cycling isn't good for power transistors in general. If this problem has only been going on a short while then its likely no worries to re-install the original outputs.

Glad you got it sorted!

If I were you I would install the original driver transistors. It was obvious at the get-go that they were just fine (if not, your complaint would have been quite different!!).

I would not be surprised to find that the original output devices are OK too, however intense heat cycling isn't good for power transistors in general. If this problem has only been going on a short while then its likely no worries to re-install the original outputs.

Glad you got it sorted!

Thanks. The problem has been going on for a long time (years), and also I was informed by the owner a tech previously fixed it several years ago, which explains why the thermal diodes were not touching the transistors on the burned channel, when they should have been, so it has been repaired before for the same problem. That's why I was suspicious that the drivers are also thermally stressed, being the rest of the board is cooked. The outputs are still good also, but the new OnSemi Outputs were slightly easier to set the bias, although there were more issues with the amp.

I usually replace drivers with outputs most of the time anyway. Call it what you like.

I also discovered two of the capacitors I upgraded (63V, 47uf) and the rubber vents (on the bottom of old Elnas) are bulged, and they are lighter in weight on the cooked channel, which is evidence of the old ones drying out. The 63V, 100uf ones . However, they all still measure good with a cap checker, but I swapped them anyway with new 100v, 150uf.

I also upgraded the 0.1uf Zobel caps to 400V 0.1uf parts, as even before I found the issue, the bias was slightly less finicky after swapping them, so they must have helped very slightly, although I don't have a scope to confirm that, I know they are subject to the full amps output voltage, and new 400V ones would be less worn or stressed.

Last edited:

The last post verified most of the problems on this thread

if you relate the zobel capacitors with the bias problem either your amplifier is oscillating or you have no idea about amplifier repairs ....

I am seriously out of here good luck !

if you relate the zobel capacitors with the bias problem either your amplifier is oscillating or you have no idea about amplifier repairs ....

I am seriously out of here good luck !

Amp is finished an about to be put back together.

I adjusted Both channels bias to ~40mV across emitter resistors (80mA) Stock bias in the good channel originally was 30mA. They are easy to set with each other, staying almost biased the same. The bias falls quickly after heating up the amp and then cooling it back down, showing proof of great temperature compensation.

Sounds good with this much bias, so I'll stick with it.

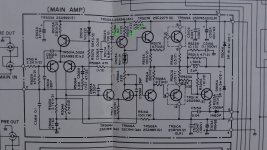

Pictures of reworked board with upgrades. Also parts pulled from amp. I forgot to put the replaced heatsink diode from right side in the picture, but I'm not going to retake it just for that.

Amp is done and sounds good, thanks for all the help and the discussion folks!

I adjusted Both channels bias to ~40mV across emitter resistors (80mA) Stock bias in the good channel originally was 30mA. They are easy to set with each other, staying almost biased the same. The bias falls quickly after heating up the amp and then cooling it back down, showing proof of great temperature compensation.

Sounds good with this much bias, so I'll stick with it.

Pictures of reworked board with upgrades. Also parts pulled from amp. I forgot to put the replaced heatsink diode from right side in the picture, but I'm not going to retake it just for that.

Amp is done and sounds good, thanks for all the help and the discussion folks!

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Unstable Bias Realistic STA-2080