Voice Coil measured it with 2.8V drive in this manner:

"... the Listen, Inc. AmpConnect ISC analyzer and 0.25” SCM microphone and SoundConnect power supply to measure distortion and generate time-frequency plots. For the distortion measurement, I again mounted the DFM-2535R00-08/(Eminence) APT 150S (100° × 50° constant directivity horn) combination in free-air in the same manner as was used for the frequency response measurements, and set the SPL to 104 dB at 1 m (2.8 V determined by using a pink noise stimulus generator and internal SLM in the SoundCheck 15 software). Then, I measured the distortion with the Listen microphone placed 10 cm from the mouth of the horn. This produced the distortion curves shown in Figure 10."

Reference:

https://audioxpress.com/article/peerless-by-tymphany-dfm-2535r00-08-compression-driver

Here it my sample driven at 2.83V, microphone at 0.5m. NB. the fundamental is smoothed with a 1/24th octave filter by REW.

"... the Listen, Inc. AmpConnect ISC analyzer and 0.25” SCM microphone and SoundConnect power supply to measure distortion and generate time-frequency plots. For the distortion measurement, I again mounted the DFM-2535R00-08/(Eminence) APT 150S (100° × 50° constant directivity horn) combination in free-air in the same manner as was used for the frequency response measurements, and set the SPL to 104 dB at 1 m (2.8 V determined by using a pink noise stimulus generator and internal SLM in the SoundCheck 15 software). Then, I measured the distortion with the Listen microphone placed 10 cm from the mouth of the horn. This produced the distortion curves shown in Figure 10."

Reference:

https://audioxpress.com/article/peerless-by-tymphany-dfm-2535r00-08-compression-driver

Here it my sample driven at 2.83V, microphone at 0.5m. NB. the fundamental is smoothed with a 1/24th octave filter by REW.

@vineethkumar01

In your design, what XO are you targeting in your 3 way design thread.

Wondering if I can do some compression or distortion testing at various drive levels and XO points to compare and contrast.

I was thinking 104dB, 96dB, and 86dB @1m.

And acoustic LR4 @ 1.5Khz down to 800Hz, and/or LR2…

I will organise to get different WG/horns at later date…

In your design, what XO are you targeting in your 3 way design thread.

Wondering if I can do some compression or distortion testing at various drive levels and XO points to compare and contrast.

I was thinking 104dB, 96dB, and 86dB @1m.

And acoustic LR4 @ 1.5Khz down to 800Hz, and/or LR2…

I will organise to get different WG/horns at later date…

Last edited:

@tktran303: Thanks.. 🙂

I plan to try out something like a 1.3 to 1.5 kHz crossover if I use the DFM2535 driver. The crossover will probably be some 4th order slope

I also have a B&C DE360, which is competing with the DFM2535 to go on the same horn (still under design iterations.. 😀).

I may also try out a Gen2 A520G2 horn in future with the DFM2535.. But not sure of a crossover point now..

Given the large size, I would like to go as much down in frequency as possible..

I plan to try out something like a 1.3 to 1.5 kHz crossover if I use the DFM2535 driver. The crossover will probably be some 4th order slope

I also have a B&C DE360, which is competing with the DFM2535 to go on the same horn (still under design iterations.. 😀).

I may also try out a Gen2 A520G2 horn in future with the DFM2535.. But not sure of a crossover point now..

Given the large size, I would like to go as much down in frequency as possible..

I will test for acoustic LR4 1.3KHz at 86dB, 96dB and 104dB @1m

If successful I will lower XO point by 1/6 octave and repeat

If successful I will lower XO point by 1/6 octave and repeat

86dB is a walk in the park- All harmonics are buried beneath this room's noise floor.

for @b_force:

Back to regular programming:

@Moderation Team

What are the chances of modifying the title to ..."Tymphany DFM-2335-R00-08 in various horns or waveguides" ?

What are the chances of modifying the title to ..."Tymphany DFM-2335-R00-08 in various horns or waveguides" ?

People with eye problems still have to suffer I guess? 🙁 🙁Back to regular programming:

Also can you explain to me how on earth you would know that the distortion is rising with this current rate of the previous picture with absolute distortion numbers?

Which is needed to determine the crossover frequency of the driver.

As we know, crossover frequency depends on various factors. One of those is the required SPL- on the low end this is limited by the excursion, the high end it's limited by thermal power handling. If you need this compression driver to attain over 150dB like this JBL in a plane wave tube , it just won't do it, irrespective of crossover frequency.

As @weltersys noted, this underperforming Public Address compression driver turns out to be a nice frequency driver for the home (albeit unavailable in unit quantities)

An alternative to using harmonic distortion testing to determine a XO frequency, which is an iterative process requiring human intervention, would be to use THD vs drive level with the Stepped Sine method. With the test frequency at Fs, we can set the software to step up the drive level and stop testing when the distortion hits a certain threshold e.g. 1, 3 or 10%.

Once we confirm the maximum SPL at this frequency, we can calculate our XO frequency and stope.

Last edited:

Here are some alternatives of determining a crossover point.

Option 0: Cross over one octave above Fs (traditional "rule of thumb" method)

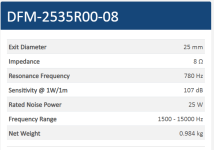

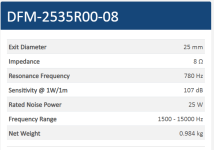

The Fs is stated 780Hz according to the specification, so based on this advice, crossover point should be around 780Hz x 2 = 1.56 KHz.

Advantages - No measurement equipment required.

Disadvantages - Without measurement equipment, no way to verify accuracy of this claim (i.e.. is it higher or lower than necessary, and what crossover slope are we talking about anyway?)

What if we look at the impedance trace?

Note the left vertical axis- impedance is "with LTH142 test horn"... a web search shows...errr, is this the FaitalPRO LTH142 horn ?

Now Fs is 630Hz. You may ask- is it because of the because of manufacturing tolerances for the particular sample (usually +/- 10 considered acceptable) or is it because of the horn? (Spoiler below)

Disadvantages: Relies on manufacturer supplied data / test conditions; what if you don't use it the same way manufacturer e.g. not their test horn, not on infinite baffle etc.

Option 1: Take simple measurements- impedance trace and/or frequency response.

Blue is bare DFM2335; Fs= ~760 Hz

Green is with H225 horn: Fs= 600 Hz.

On axis response- Note the drop in response starts below 1100Hz:

Choose XO point at twice Fs or where the device starts to lose output i.e. 1100Hz

Advantages: You can use your own horn or waveguide

Disadvantages: Needs investment in time to learn how to test.

Build an impedance jig for $10

Buy a microphone and audio interface for $100

Needs some investment in money and/time for equipment for measuring impedance or frequency response- this is perhaps the greater challenge.

Option 2: Do some distortion testing (as covered in this thread)

Here is an alternative to sine sweep testing- Stepped sine @ Fs 😱

Cursor shows the maximum SPL is 77dB dB for 1% (-40dB) THD at 600Hz. Not shown by cursor, but maximum SPL for 3% THD(-30dB) at 600Hz is 87dB.

Recall that by first principles, a high pass filter with an acoustic LR4 response will reduce the SPL by 24dB at 1 octave below the crossover point.

ie. acoustic LR4 1200Hz, the -6dB point is 1200Hz, and the -24dB point is 600Hz.

So in reverse, the maximum SPL is 77 + 24 = 101dB (with THD <1%), and 87+24= 111dB (with THD <3%)

Is this enough dynamic range for life-like music reproduction in a room? I would say so.

Advantages: Avoid iterative testing at various crossover points and slopes. Can specify end points eg. 10%, 3% or 1% THD, thus testing is short in duration.

Disadvantages: Relies on some assumptions that may not be correct in practice. e.g. driver's behavior above or below Fs.

Easy way to destroy your driver if not careful e.g. accidentally sending your drivers a few volts whilst testing at Fs can destroy it.

Option 3: Don't do any testing. Just choose drivers with smoother frequency responses, higher SPL capabilities, more power handling, and the directivity you desire/require.

Disadvantages- speaker may be larger than you require/desire, more costly than necessary.

Real engineers do more with less (tm)

Option 0: Cross over one octave above Fs (traditional "rule of thumb" method)

The Fs is stated 780Hz according to the specification, so based on this advice, crossover point should be around 780Hz x 2 = 1.56 KHz.

Advantages - No measurement equipment required.

Disadvantages - Without measurement equipment, no way to verify accuracy of this claim (i.e.. is it higher or lower than necessary, and what crossover slope are we talking about anyway?)

What if we look at the impedance trace?

Note the left vertical axis- impedance is "with LTH142 test horn"... a web search shows...errr, is this the FaitalPRO LTH142 horn ?

Now Fs is 630Hz. You may ask- is it because of the because of manufacturing tolerances for the particular sample (usually +/- 10 considered acceptable) or is it because of the horn? (Spoiler below)

Disadvantages: Relies on manufacturer supplied data / test conditions; what if you don't use it the same way manufacturer e.g. not their test horn, not on infinite baffle etc.

Option 1: Take simple measurements- impedance trace and/or frequency response.

Blue is bare DFM2335; Fs= ~760 Hz

Green is with H225 horn: Fs= 600 Hz.

On axis response- Note the drop in response starts below 1100Hz:

Choose XO point at twice Fs or where the device starts to lose output i.e. 1100Hz

Advantages: You can use your own horn or waveguide

Disadvantages: Needs investment in time to learn how to test.

Build an impedance jig for $10

Buy a microphone and audio interface for $100

Needs some investment in money and/time for equipment for measuring impedance or frequency response- this is perhaps the greater challenge.

Option 2: Do some distortion testing (as covered in this thread)

Here is an alternative to sine sweep testing- Stepped sine @ Fs 😱

NOT RECOMMENDED

Do not try this at home

Do not try this at home

Cursor shows the maximum SPL is 77dB dB for 1% (-40dB) THD at 600Hz. Not shown by cursor, but maximum SPL for 3% THD(-30dB) at 600Hz is 87dB.

Recall that by first principles, a high pass filter with an acoustic LR4 response will reduce the SPL by 24dB at 1 octave below the crossover point.

ie. acoustic LR4 1200Hz, the -6dB point is 1200Hz, and the -24dB point is 600Hz.

So in reverse, the maximum SPL is 77 + 24 = 101dB (with THD <1%), and 87+24= 111dB (with THD <3%)

Is this enough dynamic range for life-like music reproduction in a room? I would say so.

Advantages: Avoid iterative testing at various crossover points and slopes. Can specify end points eg. 10%, 3% or 1% THD, thus testing is short in duration.

Disadvantages: Relies on some assumptions that may not be correct in practice. e.g. driver's behavior above or below Fs.

Easy way to destroy your driver if not careful e.g. accidentally sending your drivers a few volts whilst testing at Fs can destroy it.

NOT RECOMMENDED

Option 3: Don't do any testing. Just choose drivers with smoother frequency responses, higher SPL capabilities, more power handling, and the directivity you desire/require.

Disadvantages- speaker may be larger than you require/desire, more costly than necessary.

Real engineers do more with less (tm)

Last edited:

Thanks for the post in the group buy thread, nice incentive for potential buyers 😉

Would you share the data? What I would be interested in is shifting fundamental and harmonics by -6 dB, so that it is easier to read for an 96 dB SPL level at 1 m, and also, if that is possible, a graph that shows relative distortion in percentages instead.

Me too.

My two:

Would you share the data? What I would be interested in is shifting fundamental and harmonics by -6 dB, so that it is easier to read for an 96 dB SPL level at 1 m, and also, if that is possible, a graph that shows relative distortion in percentages instead.

Can anyone hazard a guess what a passive XO for this combo might look like, maybe 1khz high pass. ?

I'm not familiar flattening the response of horns/waveguides. Do we add a 1st order hi pass way up to try to tilt the whole curve towards flat, or is a wide notch needed?

I have the H225 here now and I was in the GB for the DFM2335 kindly set up by @sheeple , so I'm looking forward to getting stuck in.

Thanks

I'm not familiar flattening the response of horns/waveguides. Do we add a 1st order hi pass way up to try to tilt the whole curve towards flat, or is a wide notch needed?

I have the H225 here now and I was in the GB for the DFM2335 kindly set up by @sheeple , so I'm looking forward to getting stuck in.

Thanks

For HiFi 1k looks reasonable, which is quite an amazing accomplishment with a 34mm VC (though it doesn't reach 20k), for PA use, I found the K3 (H3) not acceptable below 2,2k at the rated input. If you stay below ~118dB, 1,8k may be feasable for PA. The horn is good, good dispersion, works fine for a broad number of drivers, I was surprised by the good behaviour with several drivers so I bought 4 additional ones for future projects because of the attractive price.

DFM-2535R00-08 with the ATH A460 waveguide designed by MaBat:

- https://at-horns.eu/A460.html

Measurement by Dkalsi:

- https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7804444

- https://at-horns.eu/A460.html

Measurement by Dkalsi:

- https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7804444

Both good but not CD. It depends on the use if that's an option. No distortion measurements but the loading down low is kinda impressive. Though price/performance of the SB Audience H225 can't be beaten by any margin. The lower co frequency isn't extended as much as how much bigger it is. And it is HUGE! I don't know how the OP wants to use it but for PA use the size is way too big for the c/o frequency.

E: It's not the OP, it's @jimk04, sorry for that mistake. Jim, what do you want to use it for?

E: It's not the OP, it's @jimk04, sorry for that mistake. Jim, what do you want to use it for?

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Tymphany DFM-2535-R00-08 in SB Audience H225 90x60 degree constant directivity horn