Hello all,

First time builder, I am working on the Zaph ZBM4 bargain mini's, my question is this;

I got some help building the enclosures, however I now notice that the tweeter, a rear-mount Aura NT1 titanium dome, does not quite mount flush with the front of the baffle; it sits about .5mm below the surface. Is this something to be worried about from a sound quality perspective?

I am picturing sound waves emanating from the dome and hitting that "ridge," and thus not "flowing" across the surface of the baffle properly, but I wanted a 2nd opinion before I start chipping away at the back of my baffle (with my inexperienced fingers).

P.S.; As Zaph suggests, getting the proper diameter hole drilled for these unusual tweeters was the most difficult part of this project. My uncle who is a skilled craftsman with ~35 yrs experience really wrestled with it, and we still ended up with holes that are a tad too big - about .25mm gap all around. Of course if we had just ordered the proper drill bit as he initially suggested I'm sure that would have improved the outcome! However I insisted it "doesn't have to be perfect," and am now regretting that decision slightly.

Thanks for any help or suggestions,

Sam T

First time builder, I am working on the Zaph ZBM4 bargain mini's, my question is this;

I got some help building the enclosures, however I now notice that the tweeter, a rear-mount Aura NT1 titanium dome, does not quite mount flush with the front of the baffle; it sits about .5mm below the surface. Is this something to be worried about from a sound quality perspective?

I am picturing sound waves emanating from the dome and hitting that "ridge," and thus not "flowing" across the surface of the baffle properly, but I wanted a 2nd opinion before I start chipping away at the back of my baffle (with my inexperienced fingers).

P.S.; As Zaph suggests, getting the proper diameter hole drilled for these unusual tweeters was the most difficult part of this project. My uncle who is a skilled craftsman with ~35 yrs experience really wrestled with it, and we still ended up with holes that are a tad too big - about .25mm gap all around. Of course if we had just ordered the proper drill bit as he initially suggested I'm sure that would have improved the outcome! However I insisted it "doesn't have to be perfect," and am now regretting that decision slightly.

Thanks for any help or suggestions,

Sam T

I don't know that a half millimeter would make any audible difference, but one posssible remedy would be to sand the edges of the cutout so they are rounded over, to get rid of the sharp edge and make a sort of continuation of the tweeter housing.

Hi,

Almost certainly, as there will be a discontinuity over the surface which the sound-waves will travel, there will be some diffraction effects here with what you have ended up with.

Whether this will be serious enough to affect the sonic performance for this to be noticeable to you or not, is another matter, though.

Another possibility which you might try in order to eliminate this slight 'step' would be if you could shamfer this edge and blend it into the surrounding baffle area.

Regards,

EDIT, I hadn't seen the intervening post when I wrote this, but it seems that we are in agreement here.🙂

Almost certainly, as there will be a discontinuity over the surface which the sound-waves will travel, there will be some diffraction effects here with what you have ended up with.

Whether this will be serious enough to affect the sonic performance for this to be noticeable to you or not, is another matter, though.

Another possibility which you might try in order to eliminate this slight 'step' would be if you could shamfer this edge and blend it into the surrounding baffle area.

Regards,

EDIT, I hadn't seen the intervening post when I wrote this, but it seems that we are in agreement here.🙂

We're in agreement - plus I think it would look kinda cool too - like it was planned in the first place.

Also, if the cutout is a little too large for the tweeter, I'm thinking something like gasketing tape might be a good way to fill in the gap, albeit it's a small gap.

Also, if the cutout is a little too large for the tweeter, I'm thinking something like gasketing tape might be a good way to fill in the gap, albeit it's a small gap.

sdclc126 said:I don't know that a half millimeter would make any audible difference, but one posssible remedy would be to sand the edges of the cutout so they are rounded over, to get rid of the sharp edge and make a sort of continuation of the tweeter housing.

Thanks guys, I had thought of maybe sanding the sharp edges, so it sounds like that might be the way to go. One problem with this will be getting it to look even all around the hole, but I'm not in a hurry so hopefully with a little patience...

Not sure what to do about the gap, but I will look into the gasketing tape.

Your local hardware store may have a very small barrel sander attachment for your drill. This will speed up the 'roughing' part of it, leaving a small amount of hand sanding.

The error in question here is 0.5mm or .02 inch, that's very small.

Looking at the spec sheet, from the face of the flange to the front of the tweeter is 12mm or .47 inches, and I assume you have it back mounted in .75 inch wood. That means you must have cut some kind of recess in the back of the front panel to move the tweeter forward to

the very edge of the out face of the front panel. Correct?

Exactly how did you accomplish this? Cut a large recess to accommodate the flange then a smaller hole to accommodate the tweeter itself. Or is the recess in the rear square?

You only need .02 inches, I would think it wouldn't take that much to scrap that out of the rear recess.

Other wise, simply beveling or rounding the edges of the outer opening shouldn't be that hard. At worst, you a just extending the horn of the tweeter.

Since this is such a fine amount, I don't see why it couldn't be done by hand with some sandpaper.

Just a few thoughts.

Steve/bluewizard

Looking at the spec sheet, from the face of the flange to the front of the tweeter is 12mm or .47 inches, and I assume you have it back mounted in .75 inch wood. That means you must have cut some kind of recess in the back of the front panel to move the tweeter forward to

the very edge of the out face of the front panel. Correct?

Exactly how did you accomplish this? Cut a large recess to accommodate the flange then a smaller hole to accommodate the tweeter itself. Or is the recess in the rear square?

You only need .02 inches, I would think it wouldn't take that much to scrap that out of the rear recess.

Other wise, simply beveling or rounding the edges of the outer opening shouldn't be that hard. At worst, you a just extending the horn of the tweeter.

Since this is such a fine amount, I don't see why it couldn't be done by hand with some sandpaper.

Just a few thoughts.

Steve/bluewizard

Hi,

I tend to agree with BlueWizard's suggestion here, and unless the baffle is extremely hard wood, I think that any mechanical sanding will tend to run away with you if you are not very careful.

I would do this with some fine abrasive paper wrapped around a piece of wood of a suitable size and shape. You will have far more control over doing it this way, and I reckon that just a few 'wipes' in a circular manner around the edge of the aperture will be all that you will need here.

Why not practice a bit on some scrap wood of a similar type (I assume you will probably have some off-cuts) and you will soon see how much effort is needed for this, and a technique can be developed. Once you have 'gone too far' with the baffles, themselves, there will be no going back (or at least not easily), so do take it slowly so that you don't risk spoiling your work.

Another thought which I might try if it was me doing this, would be to temporarily stick some abrasive paper on the back of a suitably-sized shallow dish-shaped article (maybe a saucer, or pan-lid or something similar) which overlaps the hole edge by a sensible amount. Placing this over the hole, and carefully rotating it concentrically a few times should give a nice 'professionally-finished' shallow bevel which will be even all around, if you are careful with this, and the depth of cut will be easier to control.

You won't need to cover the entire circumference of the saucer-shaped 'former', and just a strip of sandpaper will do for this, but the remainder of the 'former' will help to centralise everything and support things so you almost certainly couldn't get this chamfer wrong.

Regards,

I tend to agree with BlueWizard's suggestion here, and unless the baffle is extremely hard wood, I think that any mechanical sanding will tend to run away with you if you are not very careful.

I would do this with some fine abrasive paper wrapped around a piece of wood of a suitable size and shape. You will have far more control over doing it this way, and I reckon that just a few 'wipes' in a circular manner around the edge of the aperture will be all that you will need here.

Why not practice a bit on some scrap wood of a similar type (I assume you will probably have some off-cuts) and you will soon see how much effort is needed for this, and a technique can be developed. Once you have 'gone too far' with the baffles, themselves, there will be no going back (or at least not easily), so do take it slowly so that you don't risk spoiling your work.

Another thought which I might try if it was me doing this, would be to temporarily stick some abrasive paper on the back of a suitably-sized shallow dish-shaped article (maybe a saucer, or pan-lid or something similar) which overlaps the hole edge by a sensible amount. Placing this over the hole, and carefully rotating it concentrically a few times should give a nice 'professionally-finished' shallow bevel which will be even all around, if you are careful with this, and the depth of cut will be easier to control.

You won't need to cover the entire circumference of the saucer-shaped 'former', and just a strip of sandpaper will do for this, but the remainder of the 'former' will help to centralise everything and support things so you almost certainly couldn't get this chamfer wrong.

Regards,

Why don't you make a cardboard "washer" to put between the tweeter flange and the wood? Just use 0.5mm cardboard.

Simple and reversable.

It would probably help make the cabinet more airtight too.

Simple and reversable.

It would probably help make the cabinet more airtight too.

dublin78 said:Why don't you make a cardboard "washer" to put between the tweeter flange and the wood? Just use 0.5mm cardboard.

Simple and reversable.

It would probably help make the cabinet more airtight too.

Hi,

If this was a front-mounted tweeter, something like this would work very well.

However, this tweeter is rear-mounted, so any 'packing out', will worsen the problem, unfortunately.

Regards,

Why don't you make a cardboard "washer" to put between the tweeter flange and the wood? Just use 0.5mm cardboard.

I was thinking something like that until I followed the link that samtny provided - it's a rear-mounted device; so he can't just shim it forward.

Samtny, what is your baffle made of? If it's MDF or plywood, it may be possible to carefully work it down where the flange sits, so that the tweeter protrudes a bit more to be flush at the front.

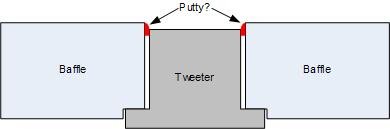

If I understand it correctly, though, you have two concerns: one is the mounting depth, the other is the gap between the tweeter and the baffle. You may be able to solve both problems by building up the gap with some sort of putty (non-stick, ideally) like the red in the drawing?

If it were mine, though, I'd listen for a while and see what it sounds like before worrying about it.

Regards.

Aengus

[edit: Bobken posted while I was drawing

)

)Attachments

Does the friend who did your woodworking have a router? If so, he should be able to use that to put a slight bevel on the edge of the hole.

That's probably more tool than you need, but it would make a perfect bevel; absolutely uniform.

I think I would be incline to just wrap some 300 grit black sandpaper over my thumb and work the edge by hand.

If there is a gap that concerns you, as illustrated in Aengus's drawing, I wouldn't worry about it. The gap should be reasonably sealed at the back. So, it's presence in the front should have no effect.

Again, the amount you need to remove is so slight, the even the mildest flair or roll should be enough to over come it.

You could wrap sandpaper around a funnel, put the funnel in the hole and rotate it until you have the bevel you want. Then fine sand it with ultra-fine sandpaper (400 or 600) by hand, and you should have what you want.

It's not a big problem, and the solution simply takes a little imagination.

Steve/bluewizard

That's probably more tool than you need, but it would make a perfect bevel; absolutely uniform.

I think I would be incline to just wrap some 300 grit black sandpaper over my thumb and work the edge by hand.

If there is a gap that concerns you, as illustrated in Aengus's drawing, I wouldn't worry about it. The gap should be reasonably sealed at the back. So, it's presence in the front should have no effect.

Again, the amount you need to remove is so slight, the even the mildest flair or roll should be enough to over come it.

You could wrap sandpaper around a funnel, put the funnel in the hole and rotate it until you have the bevel you want. Then fine sand it with ultra-fine sandpaper (400 or 600) by hand, and you should have what you want.

It's not a big problem, and the solution simply takes a little imagination.

Steve/bluewizard

I wouldn't worry about it. 0.5mm is too small to be concerned. It will possibly affect frequencies (344 / 0.0005 / 8 = ) 86kHz which is well above human hearing range.

HiFiNutNut said:I wouldn't worry about it. 0.5mm is too small to be concerned. It will possibly affect frequencies (344 / 0.0005 / 8 = ) 86kHz which is well above human hearing range.

HiFiNutNut: If your calculation is correct, then you're right I'd rather not fuss with it and make a mess of the front of my baffle.

Could you tell me the source of your formula? I recognize 344 = speed of sound, .0005 = the step I'm concerned about, but what's the 8?

To all others; thanks for your suggestions! If anything, I may try sanding the backside of the baffle to get the tweeter to sit a little deeper, however if the frequency problems are in the 86kHz range I won't even bother with that.

Hi samtny,

Trying not to disagree with what some (most) others have said here, I reiterate my earlier comments in post #3, in that it is not for certain that you will notice the diffraction effects from such a small step as you have here.

However, I do not believe that these effects (nor the likely frequency) can be properly quantified by any calculation, whatever premise it is based upon, and the only way to find out for sure is to 'suck-it-and-see'.

Therefore, if it was me doing this, I would either attend to the step anyway by adopting one of the suggested means, or at least try the speakers out as they are now, before dismissing this potential problem. I imagine you wouldn't wish to start modifying the baffle fronts after you have applied any finishing process here, which might otherwise be the case if you are later dissatisfied with your sonic results.

To quote from " High Performance Loudspeakers" by Martin Colloms, an accepted authority (by most!) and long-time designer of HQ speaker systems:

"...in the case of small dome tweeters, a plane surface free of obstruction, cavities or steps is essential if irregularities in the axial frequency response caused by diffraction are to be avoided....should present a smooth contour from the edge of the dome to the front panel surface. Even the projecting screw-heads on the chassis can cause measurable changes at the higher frequencies.... produces ripples in the frequency response of typically +/- 1.5dB,... for a 25mm HF unit this can extend from 2kHz to 8kHz."

Having listened to and measured such effects many times before whilst developing speakers, and presently working with another high-end UK speaker manufacturer, I can confrim these findings and the effects do substantially spoil focus of sounds, and this impairs the overall soundstage and perceived imaging.

*IF*, the diffraction effects are audible, instead of having the HF sounds emanating from as close as possible to a single point-source, there will also be a 'shadow' of these sounds emanating from this 'ring' step around the baffle cutout, and I wouldn't think that this would be pleasing subjectively.

Regards,

Trying not to disagree with what some (most) others have said here, I reiterate my earlier comments in post #3, in that it is not for certain that you will notice the diffraction effects from such a small step as you have here.

However, I do not believe that these effects (nor the likely frequency) can be properly quantified by any calculation, whatever premise it is based upon, and the only way to find out for sure is to 'suck-it-and-see'.

Therefore, if it was me doing this, I would either attend to the step anyway by adopting one of the suggested means, or at least try the speakers out as they are now, before dismissing this potential problem. I imagine you wouldn't wish to start modifying the baffle fronts after you have applied any finishing process here, which might otherwise be the case if you are later dissatisfied with your sonic results.

To quote from " High Performance Loudspeakers" by Martin Colloms, an accepted authority (by most!) and long-time designer of HQ speaker systems:

"...in the case of small dome tweeters, a plane surface free of obstruction, cavities or steps is essential if irregularities in the axial frequency response caused by diffraction are to be avoided....should present a smooth contour from the edge of the dome to the front panel surface. Even the projecting screw-heads on the chassis can cause measurable changes at the higher frequencies.... produces ripples in the frequency response of typically +/- 1.5dB,... for a 25mm HF unit this can extend from 2kHz to 8kHz."

Having listened to and measured such effects many times before whilst developing speakers, and presently working with another high-end UK speaker manufacturer, I can confrim these findings and the effects do substantially spoil focus of sounds, and this impairs the overall soundstage and perceived imaging.

*IF*, the diffraction effects are audible, instead of having the HF sounds emanating from as close as possible to a single point-source, there will also be a 'shadow' of these sounds emanating from this 'ring' step around the baffle cutout, and I wouldn't think that this would be pleasing subjectively.

Regards,

Just a quickie update;

I ended up doing 2 things; sanded the *inner* face of the baffle to let the tweeter sit a little deeper, and also put a tiny chamfer on the front edge of the baffle, to make the tweeter housing *almost* flush. My biggest nitpick right now is the slightly ugly gap around the tweeter at about .25mm, but at least the housing is now essentially "flush mounted" to the best of my abilities.

Will post some pix soon; just had a chance to listen to the ZBM4's fully assembled last night, my observations so far;

1) "Boominess" is a problem, I know this is accentuated by my not stand-mounting the ZBM4's; they are sitting on my entertainment center, left and right of my 42" tv. I know I have options, as suggested by Zaph in his original specifications, such as blocking the port and/or introducing a BSC circuit to my crossover, but I am going to wait a bit before messin' with it. Just want to sit back and get a feel for any problems before taking corrective action. One option I do not have is stand-mounting ("No!" quoth the SO).

2) Speakers sound "small." Okay, with a 4" driver I do believe this is to be expected. This is not to say they sound "cheap," like little off-the-shelf plastic things; rather they just sound the size that they are. I have them crossed to a Dayton SUB-100, probably will play with the xover frequency as soon as I figure out how to change that on my Sony STR-DG910 receiver (any tips appreciated! the menu system doesn't seem to light up the option to change it).

3) Vocals lack emphasis compared with my old Sony 3" bass reflex cubes (not necessarily a bad thing); Soft and Wet and I Feel for You off Prince' The Hits/The B-Sides have almost inaudible vocals, and the synth backup on these tracks which seemed to "pop" before is almost non-existant. Various theories here, not passing judgement yet, again I'm going to listen carefully for a while before making any modifications. Queen's Death on Two Legs sounded fantastic by contrast, with perfect front-and-center vocals, so I'm wondering if I'm just hearing "more" of the Prince tracks, putting the vocals and synth in a different context.

4) Clarity on the top end is much better than the Sony cubes. The Sony's sound like they're being played through a telephone receiver compared to these Aura NT1 tweeters- there's just a lot more to the top-end.

Thanks again for all the tips,

Samtny

I ended up doing 2 things; sanded the *inner* face of the baffle to let the tweeter sit a little deeper, and also put a tiny chamfer on the front edge of the baffle, to make the tweeter housing *almost* flush. My biggest nitpick right now is the slightly ugly gap around the tweeter at about .25mm, but at least the housing is now essentially "flush mounted" to the best of my abilities.

Will post some pix soon; just had a chance to listen to the ZBM4's fully assembled last night, my observations so far;

1) "Boominess" is a problem, I know this is accentuated by my not stand-mounting the ZBM4's; they are sitting on my entertainment center, left and right of my 42" tv. I know I have options, as suggested by Zaph in his original specifications, such as blocking the port and/or introducing a BSC circuit to my crossover, but I am going to wait a bit before messin' with it. Just want to sit back and get a feel for any problems before taking corrective action. One option I do not have is stand-mounting ("No!" quoth the SO).

2) Speakers sound "small." Okay, with a 4" driver I do believe this is to be expected. This is not to say they sound "cheap," like little off-the-shelf plastic things; rather they just sound the size that they are. I have them crossed to a Dayton SUB-100, probably will play with the xover frequency as soon as I figure out how to change that on my Sony STR-DG910 receiver (any tips appreciated! the menu system doesn't seem to light up the option to change it).

3) Vocals lack emphasis compared with my old Sony 3" bass reflex cubes (not necessarily a bad thing); Soft and Wet and I Feel for You off Prince' The Hits/The B-Sides have almost inaudible vocals, and the synth backup on these tracks which seemed to "pop" before is almost non-existant. Various theories here, not passing judgement yet, again I'm going to listen carefully for a while before making any modifications. Queen's Death on Two Legs sounded fantastic by contrast, with perfect front-and-center vocals, so I'm wondering if I'm just hearing "more" of the Prince tracks, putting the vocals and synth in a different context.

4) Clarity on the top end is much better than the Sony cubes. The Sony's sound like they're being played through a telephone receiver compared to these Aura NT1 tweeters- there's just a lot more to the top-end.

Thanks again for all the tips,

Samtny

Hi Sam,

This sounds encouraging (no pun intended!) and you are very wise to live with these for a while before making any firm judgements.

There will be some small changes in the voicing, anyway, as new components settle in, and the voice coils, spiders and surrounds(especially the LF) will tend to 'loosen up' with some use.

I hope that you are pleased with the results after a week or so of listening to them.

Regards,

This sounds encouraging (no pun intended!) and you are very wise to live with these for a while before making any firm judgements.

There will be some small changes in the voicing, anyway, as new components settle in, and the voice coils, spiders and surrounds(especially the LF) will tend to 'loosen up' with some use.

I hope that you are pleased with the results after a week or so of listening to them.

Regards,

Here's what that sanded front edge looks like in my final enclosure;

And while we're at it, a flattering 3/4 view;

And in the wild;

Not bad for a first-ever build, if I do say so myself. Very pleased with the results, and am liking the sound more and more.

An externally hosted image should be here but it was not working when we last tested it.

And while we're at it, a flattering 3/4 view;

An externally hosted image should be here but it was not working when we last tested it.

And in the wild;

An externally hosted image should be here but it was not working when we last tested it.

Not bad for a first-ever build, if I do say so myself. Very pleased with the results, and am liking the sound more and more.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Tweeter not quite mounted flush