To keep the motor flux (and therefore the torque) constant, the variable speed method above also needs to apply V/f control that is, voltage needs to be decreased when frequency is reduced. Also, it is best not to depend on the mains frequency, as it is directly connected to the load (power) on the grid.

Those are very useful considerations, but is there a way to fix the speed issue on this turntable? Or at least find out what's causing the problem.

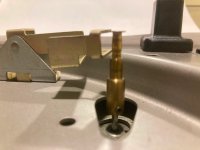

Could you attach a picture of the pulley with the belt removed? The data sticker says 50/60 Hz, an I suppose there must be some mechanical trick to change between the frequency used. Or the subplatter has a step in the diameter.

Edit:

Here is the Service Manual:

https://elektrotanya.com/sony_ps-1350_ps-2350_sm.pdf/download.html

It says the 50/60 Hz switchover is done by the pulley replacement. There is also some height adjustment. I assume if the height of the pulley is too high, the belt slips down from the 33 barrel centre towards the 45, but not fully. This could explain the slight speed increase.

Edit:

Here is the Service Manual:

https://elektrotanya.com/sony_ps-1350_ps-2350_sm.pdf/download.html

It says the 50/60 Hz switchover is done by the pulley replacement. There is also some height adjustment. I assume if the height of the pulley is too high, the belt slips down from the 33 barrel centre towards the 45, but not fully. This could explain the slight speed increase.

Attachments

Last edited:

A synchronous motor will always run at fmains*60/N RPM, where N is the number of poles. So there's no way for the motor to run fast unless the mains frequency is off, which it won't be.

Bummer about the "50 Hz pulley". Can you get one for 60 Hz? It looks like it has a set screw holding it to the motor shaft, so it should be trivial to replace ... if you can find a replacement.

I wouldn't try to file it down. A better approach would be to get to know someone with a lathe and just make a new one.

Tom

Bummer about the "50 Hz pulley". Can you get one for 60 Hz? It looks like it has a set screw holding it to the motor shaft, so it should be trivial to replace ... if you can find a replacement.

I wouldn't try to file it down. A better approach would be to get to know someone with a lathe and just make a new one.

Tom

An alternative... There are VFDs out there. Variable Frequency Drives. They're used to drive synchronous motors. You could get one of those and just feed 120 V, 50 Hz into the turntable. It might be cheaper to just get a different turntable, but I thought I'd throw it out there anyway.

... Or build one yourself. Get a 12 V oscillator going and back-feed a 120:12 V transformer to get 120 V, 50 Hz. You may have to use an audio amp like the LM3886 to drive the transformer, but it should be perfectly possible to make a 50 Hz source for the turntable.

Tom

... Or build one yourself. Get a 12 V oscillator going and back-feed a 120:12 V transformer to get 120 V, 50 Hz. You may have to use an audio amp like the LM3886 to drive the transformer, but it should be perfectly possible to make a 50 Hz source for the turntable.

Tom

No, don't do that. Try wrapping electrical tape around the platter where the belt runs, one wrap at a time and check the speed. Make sure you cut the tape diagonally with an xacto knife, so there's no gap or step. If that doesn't slow it down enough, than you're going to need the proper pulley.Maybe I can file it down to slow down the platter.

jeff

I tried a similar thing before. Used several layers of rubber belts. Did not notice much difference in speed. But now, when there is a clear understanding how that thing was designed - it may be easier to deal with. 👍

Mechanical speed changes are easy when carried out by adjusting the gear ratio. In this case, the 50Hz pulley diameter needs to be 60/50 = 1.2 times in order to bring the speed back to normal. That is a significant increase of 20%.

I'd still recommed the electronic drive as it can easily manage different RPMs for different records and remain independent of the P - f related control running on the grid.

I'd still recommed the electronic drive as it can easily manage different RPMs for different records and remain independent of the P - f related control running on the grid.

Last edited:

- Home

- Source & Line

- Analogue Source

- Turntable with a synchronous motor