Hi,

I have a Garrard 401, they did not come with AC ground, just only two wires.

I can connect a ground wire to the deck's chassis, do I connect the other end to the preamp's ground or to the ground in the IEC connector in the plinth?

Cheers,

I have a Garrard 401, they did not come with AC ground, just only two wires.

I can connect a ground wire to the deck's chassis, do I connect the other end to the preamp's ground or to the ground in the IEC connector in the plinth?

Cheers,

Common practce with the 401 would appear to be as follows:

The chassis point on a 401 should be connected to mains earth for safety reasons. You can do this via the IEC connector and connected three core mains lead.

The pickup arm base should not be connected to the chassis, but connected to the preamp ground via a separate wire.

This will give both a safe and a hum free connection.

The chassis point on a 401 should be connected to mains earth for safety reasons. You can do this via the IEC connector and connected three core mains lead.

The pickup arm base should not be connected to the chassis, but connected to the preamp ground via a separate wire.

This will give both a safe and a hum free connection.

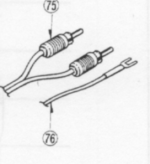

You know those 3 wire Video RCA's. Get one of good quality, not that cheap ones.

Use the Yellow wire for the ground wire. Cut the RCA and solder a fork. Join Hot & shield together. That's what I did on my old Pioneer turntable as the cable was intermittent.

Use the Yellow wire for the ground wire. Cut the RCA and solder a fork. Join Hot & shield together. That's what I did on my old Pioneer turntable as the cable was intermittent.

Ground arm to pre-amp, and TT chassis to AC mains safety earth. 😀 This is what I have done, it's also quieter than dumping the AC leakage currents from motor and switches into the pre-amp..

I have two TD-124 that are grounded this way. It's both safe and quiet.

I have two TD-124 that are grounded this way. It's both safe and quiet.

Kevin, your advice led me to modify the grounding scheme of my Thorens TD-160. I installed an IEC socket, connected the fixed chassis and the floating sub-chassis to the mains earth terminal. The original phono cable is somehow built in the arm base, the soldering points to the arm wires are not accessible. In any case, a separate ground wire is connected to the arm tube, and the other end is like JonSnell depicted. There is no continuity between the chassis and the arm ground wire. I connected the arm ground to the preamplifier, but there is still some hum in the right channel. I can see this on an oscilloscope in 1mV/div. The left channel is OK. If I turn on the motor, the ripple increases in both channels.Ground arm to pre-amp, and TT chassis to AC mains safety earth. 😀 This is what I have done, it's also quieter than dumping the AC leakage currents from motor and switches into the pre-amp..

I have two TD-124 that are grounded this way. It's both safe and quiet.

The hum is barely audible at normal listening volume, but I want to eliminate it completely.

Next step is to determine whether this partially magnetic induction into the cartridge, and wiring issues between cartridge and pre-amp.

It seems the SUT (2 x Lundahl LL1678 buit in an aluminium box picks up some magnetic field. I can reduce the hum by rotating it. Now at least I know the source.

"Aluminium box " ? according to Lundahi its screened by a MU-METAL can --its nickel-iron alloy .

Mu-metal is something I know about in RF equipment for shielding for RF front end radio equipment .

It requires careful manufacture to help suppress RF radiation --badly shaped and manufactured "cans " can leak radiation , not easy to make your own to 100 % reliability .

Mu-metal is something I know about in RF equipment for shielding for RF front end radio equipment .

It requires careful manufacture to help suppress RF radiation --badly shaped and manufactured "cans " can leak radiation , not easy to make your own to 100 % reliability .

- Home

- Source & Line

- Analogue Source

- Turntable ground to preamp or IEC connector?