Thought I would share. Feedback is appreciated.

I picked up a 12' stick of 12" sch40 PVC and decided to make a couple enclosures. I also happened to pick up a bunch of 3/4" MDF at work.

I started by cutting the PVC to length. Then I traced circles onto the MDF. I cut out four circles of MDF and carefully sanded them until they were a light press-fit. Then I cut some rectangular pieces of MDF and used marine epoxy to laminate the circle to the rectangles.

Then I dressed the inside of the PVC with a 100-grit disc on my angle grinder.

I used some leftover West Systems epoxy from a boat project. This is expensive stuff, but extremely foolproof and very high quality.

I mixed up a batch and added cotton fibers until the consistency of peanut butter. I slathered it all along the circumference of the MDF disc and the inside of the PVC. Then I simply assembled the disc by squishing the PVC down over the MDF. THen I just filetted the extra epoxy. It has formed an extremely tenacious bond to the PVC.

Here is one tube assembled with my toolbox on it for weight until it cures.

I will then use a router to cut the MDF flush with the PVC leaving one side squared for feet.

More updates and photos as I progress.

I picked up a 12' stick of 12" sch40 PVC and decided to make a couple enclosures. I also happened to pick up a bunch of 3/4" MDF at work.

I started by cutting the PVC to length. Then I traced circles onto the MDF. I cut out four circles of MDF and carefully sanded them until they were a light press-fit. Then I cut some rectangular pieces of MDF and used marine epoxy to laminate the circle to the rectangles.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Then I dressed the inside of the PVC with a 100-grit disc on my angle grinder.

An externally hosted image should be here but it was not working when we last tested it.

I used some leftover West Systems epoxy from a boat project. This is expensive stuff, but extremely foolproof and very high quality.

I mixed up a batch and added cotton fibers until the consistency of peanut butter. I slathered it all along the circumference of the MDF disc and the inside of the PVC. Then I simply assembled the disc by squishing the PVC down over the MDF. THen I just filetted the extra epoxy. It has formed an extremely tenacious bond to the PVC.

Here is one tube assembled with my toolbox on it for weight until it cures.

An externally hosted image should be here but it was not working when we last tested it.

I will then use a router to cut the MDF flush with the PVC leaving one side squared for feet.

More updates and photos as I progress.

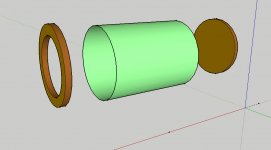

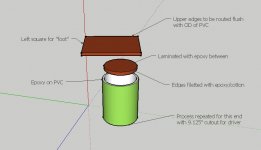

Here was the original design I had in mind seen in the first photo. I was going to just epoxy in some 3/4" MDF rings, but I had concerns about the integrity of just a single layer. So I modified it (with the advice of you folks) to include a full flat piece on the outside (second photo). This gives both baffles a full 1.5" of thickness, additional rigidity from being laminated with epoxy, and additional adhesion surface area.

With one of the tubes fully epoxied and ready for the router, I have to say it is heavy, acoustically dead, and kinda makes me a little moist. 🙂 This is the first time I've really built an enclosure with actual pride and effort instead of slapping some 3/4 MDF together with elmer's glue and some screws.

The third photo shows the first enclosure fully cured and ready for the router.

With one of the tubes fully epoxied and ready for the router, I have to say it is heavy, acoustically dead, and kinda makes me a little moist. 🙂 This is the first time I've really built an enclosure with actual pride and effort instead of slapping some 3/4 MDF together with elmer's glue and some screws.

The third photo shows the first enclosure fully cured and ready for the router.

Attachments

Need some suggestions. This will (obviously) be a sealed enclosure. The drivers for now are Kicker Comp VR 10" with dual 4-ohm coils. I had run these before in parallel/parallel with a 1-ohm stable amp and they were loud but SQ sucked. I think I'll run them this time parallel/series for 4 ohms. Sound wiser for an SQ setup?

The walls of the PVC are 3/8" thick. I can sit on them and they don't flex. I will be filling with polyfil, but should I line the ID of the PVC with something to scatter the sound waves? I never did with the matte-finish of plain old MDF boxes, but would I benefit (giving up a wee bit of volume) to line the inside with something?

The walls of the PVC are 3/8" thick. I can sit on them and they don't flex. I will be filling with polyfil, but should I line the ID of the PVC with something to scatter the sound waves? I never did with the matte-finish of plain old MDF boxes, but would I benefit (giving up a wee bit of volume) to line the inside with something?

Got em all done. Outside is coated with bedliner. I scuffed the PVC with 80 grit and cleaned it with acetone so hopefully it will adhere. I sprayed the inside with a couple coats of undercoating.

Only thing left is to put the speaker wire connectors in, polyfil, and test them.

Only thing left is to put the speaker wire connectors in, polyfil, and test them.

I have been using PVC for over 20 years for speaker enclosures. I used to sel my woofers made of 18" with 12" dual voice coil drivers for $800 and count make them fast enough. I even talked to Bob Carver about them. The tubular design isn't new but I believe it takes care of all problems with WOOD and Square/flat sided boxes. and the PVC mnaterial is nearly impervious to absorbing your sound.Then yo can hide them inside any kind of box you might want. Make sure the ends are thik enough and many layers of laminant also only minimal enough to fill up the HOLE.Yo can' tsee the tubes in my mains which I call Tomb Stones. THiese are built wiht8" Peerless 850136 woofer, Eton 4-206 Hex mids, and Vifa D19TD-05-08 3/4" Dome Tweets. I have 10" grills on the Woofs and people are amazed that I can get that much bass out of a 10" woofer and then I takke the grills off and show them the 8" Cones. YOU have never played Jazz through a better set of speaks. I see yo bolt from the ends into the PVC, WRONG methid. Put the wood inside the tubes and screw through the PVC into the Wood. I use a combo of Solen and Mundorf Caps and ONLY use RIBBON Coils. Currently I am feeding them wiht Cardis 101 wires 5 1/2 ft long, from a NAD amp. The littel one next to the mains are traditionaly built surround speqakers. If yo look closely at the BIG woofer, I have castilated the top and bottom. Down firing. Reflex. Has naugahide stiched to it and a butcherblock top deck. it is aprox 3ft tall and MUST be put in a corner to simulate a horn. Without the corner horn effect you can't hardly hear it. but with the corner i have to turn my 300W amp almost off to kee it from breaking the windows. Sorry for the poor quality photos on the spur of the moment.

Attachments

The extra set of terminals you see on the upper deck of the mains is for some OLD. RS

LINAEUM TWEETERs that I plug in when the mood hits me. Don't let the RS name distract you from the quality of these well know ribbons forrom the early days. They are TRUE ribbons and noting like the modern ribbons they sell today.

LINAEUM TWEETERs that I plug in when the mood hits me. Don't let the RS name distract you from the quality of these well know ribbons forrom the early days. They are TRUE ribbons and noting like the modern ribbons they sell today.

I appreciate the reply. I built these in 2014 and they're still pounding today. Yours are prettier than mine 🙂

If you look back over the pictures, I didn't bolt them into the ends of the PVC. There are two layers of 3/4" MDF - one is cut as a press-fit inside the tube and the other is laminated to the outside. There are no screws at all, just epoxy. Like this:

If you look back over the pictures, I didn't bolt them into the ends of the PVC. There are two layers of 3/4" MDF - one is cut as a press-fit inside the tube and the other is laminated to the outside. There are no screws at all, just epoxy. Like this:

I have 2 give-away woofer projects here for giveaway (if you can pick them up). Pairs of woofers in each case. Come with active XO (needs a little TLC).

A cylinder is a very stiff enclosure, the ends are the weakest, so a double layer like you are showing is recommended. I do not use MDF thou.

One of mine uses 4 12" in a push-push push-pull isobaric configuration, it was inspired by things like this, a nice chunk of free 12” PVC pipe, and 16-some Foster woofers.

dave

A cylinder is a very stiff enclosure, the ends are the weakest, so a double layer like you are showing is recommended. I do not use MDF thou.

One of mine uses 4 12" in a push-push push-pull isobaric configuration, it was inspired by things like this, a nice chunk of free 12” PVC pipe, and 16-some Foster woofers.

dave

I totally approve of the method and reasoning behind the double ends. I prefer wood glue or Gorilla glue, to Epoxy though. Pretty much doesn't make anything sound good, but it doesn't hurt. My speakers are from about 2000. I like the options. of putting the tubes into something attractive as I was designing for other people. I don't think Martin Logans or B & Ws would sell very well if they didn't have nice-looking cabinets. I try to use only BRASS screws just in case steel screws might influence the magnetic fields of the speaker magnets. Not that there would actually be much influence, but I always try to OVER engineer everything I do. I am really happy to see someone else that had a similar thought to me independently. I don't like trying to take credit for such a simple idea. Sound waves are ROUND (emanating pattern) and in air pressure, so the air pressure in the cabinet is as equal as possible. also when you consider sound as pressure and vibrations, 'I' don't want my cabinet absorbing those waves in a wooden enclosure so YES the PVC is perfect.

- Home

- General Interest

- Car Audio

- tubular sub enclosure build thread

![20220714_135247[1].jpg](/community/data/attachments/980/980106-ca69c325c969c17905410e0c75457bf6.jpg?hash=ymnDJclpwX)

![20220714_135220[1].jpg](/community/data/attachments/980/980107-f18d9de7b8a7832089ec2cd42655fdd7.jpg?hash=8Y2d57ingy)

![20220714_135225[1].jpg](/community/data/attachments/980/980108-5ec6449c7821559a87db507b1d281536.jpg?hash=XsZEnHghVZ)