Magnetic amplifier - Wikipedia

Are there many amps that use tube followed by the final output transformer operating as an amplifier driven by the power supply?

I'm assuming there's some gotchas?

These previously had been run at mains frequencies, with the growth of SMPS higher frequencies, I'm wondering if it's possible to combine the two (I'm going to a flaming pit I know by one sentence).

With the SMPS half-bridge, this could provide a fast 200KHz driving frequency with a saturated transformer. A tube could then provide the control through separate windings for the output followed by a filter to remove SMPS noise.

Essentially this is a tube modulated power supply.

Are there many amps that use tube followed by the final output transformer operating as an amplifier driven by the power supply?

I'm assuming there's some gotchas?

These previously had been run at mains frequencies, with the growth of SMPS higher frequencies, I'm wondering if it's possible to combine the two (I'm going to a flaming pit I know by one sentence).

With the SMPS half-bridge, this could provide a fast 200KHz driving frequency with a saturated transformer. A tube could then provide the control through separate windings for the output followed by a filter to remove SMPS noise.

Essentially this is a tube modulated power supply.

Last edited:

"Magnetic amplifiers introduce substantial harmonic distortion to the output waveform consisting entirely of the odd harmonics"

So symmetric distortion of from the transformer :/

However...

Power reduction of odd harmonics with PWM is used: http://www.iosrjournals.org/iosr-jeee/Papers/Vol10-issue4/Version-3/P010439497.JEEE%20[ZSEP02].pdf so this means we could adjust the PWM, or even chain PWM, to reduce the odd harmonics.

Additionally this https://www.rose-hulman.edu/class/ee/HTML/ECE471/PDFs/Lect15.pdf seems to highlight the use of multiple phases reduces odd harmonics.

So instead of two phases, could we make a multi-phase amp?

(PMP7969 High-Efficiency 4 Phase Synchronous Boost Conv for Automotive Trunk Amplifier App Reference Design | TI.com is a digital example I've just found doing something similar)

So symmetric distortion of from the transformer :/

However...

Power reduction of odd harmonics with PWM is used: http://www.iosrjournals.org/iosr-jeee/Papers/Vol10-issue4/Version-3/P010439497.JEEE%20[ZSEP02].pdf so this means we could adjust the PWM, or even chain PWM, to reduce the odd harmonics.

Additionally this https://www.rose-hulman.edu/class/ee/HTML/ECE471/PDFs/Lect15.pdf seems to highlight the use of multiple phases reduces odd harmonics.

So instead of two phases, could we make a multi-phase amp?

(PMP7969 High-Efficiency 4 Phase Synchronous Boost Conv for Automotive Trunk Amplifier App Reference Design | TI.com is a digital example I've just found doing something similar)

Last edited:

Excellent idea, post your own design and we´ll comment on it.Magnetic amplifier - Wikipedia

Are there many amps that use tube followed by the final output transformer operating as an amplifier driven by the power supply?......

With the SMPS half-bridge, this could provide a fast 200KHz driving frequency with a saturated transformer. A tube could then provide the control through separate windings for the output followed by a filter to remove SMPS noise.

Essentially this is a tube modulated power supply.

Be certain to show full schematic, pictures, tests,scope captures, etc.

Otherwise ....

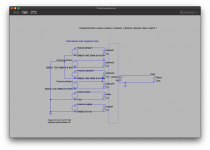

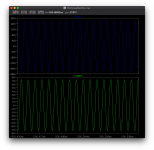

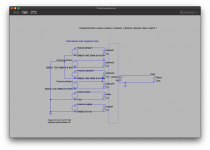

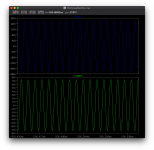

This seems to be working- first run after making the spice model - would appreciate comments.

Current this is using 200KHz sine wave, I will alter the model for 200Khz switch pulses today - just have my vaccine shot today so I'll get more time this evening.

LTSpice

View attachment TheHeresyMachine .asc

Current this is using 200KHz sine wave, I will alter the model for 200Khz switch pulses today - just have my vaccine shot today so I'll get more time this evening.

LTSpice

View attachment TheHeresyMachine .asc

Last edited:

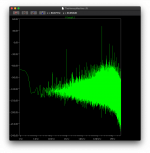

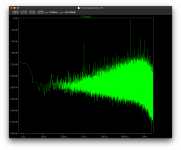

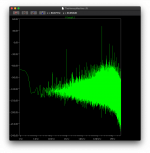

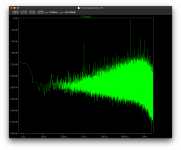

The key here is that the transformer switches in and out of saturation. Saturation creates a lot of odd harmonics which is where the SMPS switching rate allows this to be targeted.

I'll have to expand the test to a multi-tone signal to ensure this isn't just operating in one-frequency.

I'll have to expand the test to a multi-tone signal to ensure this isn't just operating in one-frequency.

Seems to be some prior amps existing with this, the Lars Lundahl Magnetic amp: MagAmp

PCB using tubes: http://www.auditorium-23.de/MagAmp/MagAmp.pdf

Patent 1950s, expired 1980s: US3131360A - Magnetic amplifier

- Google Patents

Even a thread on this here: Headphone magamp ?

The name sounds very familiar 🙂

PCB using tubes: http://www.auditorium-23.de/MagAmp/MagAmp.pdf

Patent 1950s, expired 1980s: US3131360A - Magnetic amplifier

- Google Patents

Even a thread on this here: Headphone magamp ?

The name sounds very familiar 🙂

Hard to get a linear response from something that is either on or off.

Here is an idea for a smooth control device. Take a fair size toroid core and wind a (control) winding on it, except leave two bare sections of core 180 degrees apart, about an inch wide. Now take two C section cores of the same size and wind the inductor winding on each, (50-50) split between halves.

Now butt the C section halves up against the sides of the toroid core (one on each side) at the bare spots. Forming a "cross" in the magnetic pathes where the core types meet. A big tie wrap around the C sections to hold this together.

The inductor windings now have a complete "toroid like" magnetic path that

passes thru the control toroid at the two "cross" locations.

By passing DC current thru the control toroid winding, the magnetic domains in the "cross" sections will be tilted away from the inductor magnetization path when that is active. So you now have "Vector" control of the magnetization in the "cross" sections. The effectve permeability of the "cross" sections will be the cosine of the angle tilted away from the inductor magnetic path. The two fields remain isolated due to the orthogonality of pathes. So you now have a smoothly varying controlled inductor. (to use in series with HF power to make a magnetic amplifier, audio signal applied to the higher permeability control toroid winding to control the C winding inductance)

Using two such variable inductor devices one could make a P-P output assembly. HF power converted to + or - by full wave Shottky rectifiers and those each connected with a dual voice coil speaker in opposition or some type of bridge arrangement. (there are difficulties in combining + and - rectified sources to get AC)

Here is an idea for a smooth control device. Take a fair size toroid core and wind a (control) winding on it, except leave two bare sections of core 180 degrees apart, about an inch wide. Now take two C section cores of the same size and wind the inductor winding on each, (50-50) split between halves.

Now butt the C section halves up against the sides of the toroid core (one on each side) at the bare spots. Forming a "cross" in the magnetic pathes where the core types meet. A big tie wrap around the C sections to hold this together.

The inductor windings now have a complete "toroid like" magnetic path that

passes thru the control toroid at the two "cross" locations.

By passing DC current thru the control toroid winding, the magnetic domains in the "cross" sections will be tilted away from the inductor magnetization path when that is active. So you now have "Vector" control of the magnetization in the "cross" sections. The effectve permeability of the "cross" sections will be the cosine of the angle tilted away from the inductor magnetic path. The two fields remain isolated due to the orthogonality of pathes. So you now have a smoothly varying controlled inductor. (to use in series with HF power to make a magnetic amplifier, audio signal applied to the higher permeability control toroid winding to control the C winding inductance)

Using two such variable inductor devices one could make a P-P output assembly. HF power converted to + or - by full wave Shottky rectifiers and those each connected with a dual voice coil speaker in opposition or some type of bridge arrangement. (there are difficulties in combining + and - rectified sources to get AC)

Last edited:

To build a magamp you need special transductor cores. You may google "lundahl", "transductor" "magamp" if you are interested in more details about this tecqnique that has been of some interest during ww2. Even the German manufacturer "Vacuumschmelze" do not produce these materials anymore. So this is another dead horse among many others to ride in audio forums.

The usual saturating type mag-amps need sharply saturating square loop material.

The Vector control type I mentioned above will work with conventional "linear" magnetics.

The Vector control type I mentioned above will work with conventional "linear" magnetics.

By passing DC current thru the control toroid winding, the magnetic domains in the "cross" sections will be tilted away from the inductor magnetization path when that is active. So you now have "Vector" control of the magnetization in the "cross" sections. The effectve permeability of the "cross" sections will be the cosine of the angle tilted away from the inductor magnetic path. The two fields remain isolated due to the orthogonality of pathes. So you now have a smoothly varying controlled inductor. (to use in series with HF power to make a magnetic amplifier, audio signal applied to the higher permeability control toroid winding to control the C winding inductance)

This is basically how industrial welders are controlled for constant current. I know this because I have been a welder-fabricator for decades. The industrial machines ordinarily use a 3-phase E-I core, with a DC control winding in the bottom layer. The DC winding varies the saturation, (and hence the inductance) being designed to stay on the "knee" of the saturation curve gives a constant current effect. The machine I use at work will happily put 200 amperes at 26 volts all day long into what amounts to a dead short. But I've wondered for a long time about feeding some AC into the DC control winding... say the output from a radio.

Could you provide any specs of real vector type magamps?

They just got invented. Obviously some ferrite type material will be needed to get audio modulation bandwidths.

The main drawback would be the cosine control law, instead of linear control. One could bias the control current up around 45 degree field (ie, equal HF and control bias amp turn currents x eff. permeability) to get a modest range of control that would be close to linear.

But then Cuk switching converters and related ripple free switch-mode designs have a similar control issue.

Last edited:

Turns out that the magnetics still need to operate near saturation for Vector control to work, otherwise the magnetiization would just vary in each orthogonal direction mostly independently. When the domains are saturated, then there is only so much material magnetization available, so rotating the material "induction" vector off axis by the control field will necessarily reduce the effective permeability for the induction field by the cosine of the angle. This may not look like "amplification" much if the signal has to produce saturation like levels, but the turns ratio can favor the signal highly. Likely not going to take the amplification field by storm in any case, but an interesting DIY project. Tube power can obviously amplify the signal to operate the Vector modulator, but power gain may be low in the modulator ferrite due to saturation like levels, and then one has to demodulate and combine the modulated HFs and sum them somehow, and linearize (N Fdbk loop) the whole thing. Tube power also needed to produce the carrier HF used in it. So two tube amps required. Probably going end up on the shelf after a lot of work to reach a proof of concept level.

In any case, I suggest the OP take a look at the David Berning scheme for a HF ferrite impedance converter OT. Very straightforward to design and implement. Only down side is that leakage L is suffered at the HF carrier, and filtering is needed to remove the HF carrier from the output audio which will complicate any global N Fdbk loop. And no magnetic amplification is involved, just conventional tube power.

In any case, I suggest the OP take a look at the David Berning scheme for a HF ferrite impedance converter OT. Very straightforward to design and implement. Only down side is that leakage L is suffered at the HF carrier, and filtering is needed to remove the HF carrier from the output audio which will complicate any global N Fdbk loop. And no magnetic amplification is involved, just conventional tube power.

Last edited:

Looking at the Berning HF impedance converter, I see some room to expand the idea to "magnetic" amplification as well.

Now the HF switching (done by Mosfets) is nominally not frequency dependent, it just has to be above the audio band enough to be filtered out easily.

Suppose we -intentionally- put leakage L into the ferrite xfmrs and then vary the switching frequency using the audio signal V level in a complementary way.

Ie, when one xfmr switching goes up in frequency, the other xfmr (one xfmr for each P-P tube) goes down in freq. This way the two tubes become more or less coupled to the output versus signal thru the leakage Ls. Now if each tube were just a short, we would have a conventional (complementary) PWM scheme. But we can drive the tubes as well, and incorporate N Fdbk into that drive as well. So we have a magnetically assisted amplifier. Notice that the tubes are always connected to the output in corrent phase, (just the ferrite xfmr is being flipped around in polarity by the HF) so there is no PWM like dead time here.

The ferrite xfmrs will have to handle the freq range of the HF modulation. They do still maintain DC neutrality for each tube/xfmr via the switching, so audio band is kept out of them. And the HF voltage developed across them will be proportional to the switching frequency. Ie, when a tube is conducting heavily, the voltage across the tube/xfmr becomes lower, and the switching frequency becomes lower (via control) to better couple to the output. So peak magnetization within the ferrite xfmr becomes constant versus signal. This will help remove any magnetic distortion due to the ferrite HF magnetization current.

One could also tailor the switching freq. control to help remove tube non-linear distortion. This may occur almost naturally. As a tube turns off, the gm goes down, but the higher switching freq also decouples the tube more. Effectively making the tube gm seem more constant by increasing the effect, I think. Well some analysis needed for optimal switching freq. control.

Well, just an idea. No magnetic saturation involved in this scheme, so will remain efficient.

Now the HF switching (done by Mosfets) is nominally not frequency dependent, it just has to be above the audio band enough to be filtered out easily.

Suppose we -intentionally- put leakage L into the ferrite xfmrs and then vary the switching frequency using the audio signal V level in a complementary way.

Ie, when one xfmr switching goes up in frequency, the other xfmr (one xfmr for each P-P tube) goes down in freq. This way the two tubes become more or less coupled to the output versus signal thru the leakage Ls. Now if each tube were just a short, we would have a conventional (complementary) PWM scheme. But we can drive the tubes as well, and incorporate N Fdbk into that drive as well. So we have a magnetically assisted amplifier. Notice that the tubes are always connected to the output in corrent phase, (just the ferrite xfmr is being flipped around in polarity by the HF) so there is no PWM like dead time here.

The ferrite xfmrs will have to handle the freq range of the HF modulation. They do still maintain DC neutrality for each tube/xfmr via the switching, so audio band is kept out of them. And the HF voltage developed across them will be proportional to the switching frequency. Ie, when a tube is conducting heavily, the voltage across the tube/xfmr becomes lower, and the switching frequency becomes lower (via control) to better couple to the output. So peak magnetization within the ferrite xfmr becomes constant versus signal. This will help remove any magnetic distortion due to the ferrite HF magnetization current.

One could also tailor the switching freq. control to help remove tube non-linear distortion. This may occur almost naturally. As a tube turns off, the gm goes down, but the higher switching freq also decouples the tube more. Effectively making the tube gm seem more constant by increasing the effect, I think. Well some analysis needed for optimal switching freq. control.

Well, just an idea. No magnetic saturation involved in this scheme, so will remain efficient.

Last edited:

One note on using intentional xfmr leakage L and switching freq. to modulate output (as in the above scheme). The tube must be a near V source, not a current source for xfmr leakage L reactance (at the variable switching freq.) to make any difference in conduction (by variable voltage drop). So beam type tubes would need local N Fdbk to lower their output Z.

I should point out that this variable switching freq scheme can also be looked at as a variable ratio OT, since the voltage referred back to the tube can be varied within some range. Although the current transform ratio remains the same, determined by the turns ratio.

The leakage reactance (suffered at the HF carrier freq) acts to raise the output Z as well. Not so attractive there. Global N Fdbk would be required to bring it back down.

I should point out that this variable switching freq scheme can also be looked at as a variable ratio OT, since the voltage referred back to the tube can be varied within some range. Although the current transform ratio remains the same, determined by the turns ratio.

The leakage reactance (suffered at the HF carrier freq) acts to raise the output Z as well. Not so attractive there. Global N Fdbk would be required to bring it back down.

Last edited:

I was researching this - feeling pretty under the weather yesterday following the covid jab.

1. It seems that for the best performance that you need specific core composition which is different to the standard composition.

2. For AC use the rectangular loops, however it can be made to work for DC input using a gapped transformer (same form used for flyback)

3. I did find a DIY version here: The Magnetic Amplifier | Nuts & Volts Magazine

I'll have to have a look at the vectorisation.

1. It seems that for the best performance that you need specific core composition which is different to the standard composition.

2. For AC use the rectangular loops, however it can be made to work for DC input using a gapped transformer (same form used for flyback)

3. I did find a DIY version here: The Magnetic Amplifier | Nuts & Volts Magazine

I'll have to have a look at the vectorisation.

Many years ago I wandered down a road toward something I called the Solid State output Transformer. Fortunately, before I got too far down that road, I was informed that what I was doing would likely violate the patents and IP of someone who had already invented something similar and was using that technology in commercial products. These patents have since expired, so everyone is now able to play in that sandbox.

Attachments

Most anything that can convert from LV to HV can be configured to do impedance conversion. With some finesse, some schemes can be configured to do variable impedance controlled amplification too.

For example, the Greinacher / Cockcroft-Walton voltage multiplier schemes can be used. Take the LV Mosfet switching scheme from the Berning design and substitute a capacitor/diode voltage multiplier in place of the HF Ferrite xfmr normally used there. 10 capacitor/diode stages will give 10X voltage boost ( 100X impedance ), but will reduce the bandwidth to 1/10 the switching frequency as the signal propagates thru. The tube(s) go across the HV terminals to draw current at the high Z end, while the low Z (Mosfet switches end ) will draw 10X the current thru the speaker from the + and - LV supplies. ( + and -, so two converter units, each with a tube ) A full wave V multiplier is preferred for minimal ripple.

It can be refined further to use a resonant scheme, with both a moderately low ratio Ferrite xfmr -and- a moderate ratio cap/diode multiplier in cascade (C multiplier above the xfmr, product of the ratios then ). This allows the leakage inductance of the xfmr to be resonated with the effective series capacitance of the multiplier at the switching frequency. So effectively removing the parasitic series capacitance of the C multiplier and the leakage L of the Ferrite xfmr to give a very high damping factor output. (the Berning scheme suffers the xfmr leakage L at the carrier freq. and then needs N Fdbk around the conversion to fix that, to get V output instead of I output )

------------------------------

The Vector saturating field scheme can be done for electric fields besides magnetic fields. Take two long strips of thin metal with a saturable high permittivity dielectric film between them. (an un-wound capacitor essentially). Wires from each strip at one end (or side) for the capacitor leads. Then wind the elongated capacitor assembly on a large core area Ferrite xfmr core, with a secondary copper wire control winding wound on the core too. Placing HV HF voltage on the copper winding induces voltage along the cap strip length, and through the dielectric, without producing a voltage across the "capacitor". If the voltage along the length of the dielectric is sufficient to saturate the dielectric dipoles, then the capacitance between the strips will fall significantly. So varying the HF voltage controls the capacitance.

Varactor bridges are used for a somewhat similar capacitance modulation effect (but not orthogonal fields ). Too small a capacitance for audio I think.

For example, the Greinacher / Cockcroft-Walton voltage multiplier schemes can be used. Take the LV Mosfet switching scheme from the Berning design and substitute a capacitor/diode voltage multiplier in place of the HF Ferrite xfmr normally used there. 10 capacitor/diode stages will give 10X voltage boost ( 100X impedance ), but will reduce the bandwidth to 1/10 the switching frequency as the signal propagates thru. The tube(s) go across the HV terminals to draw current at the high Z end, while the low Z (Mosfet switches end ) will draw 10X the current thru the speaker from the + and - LV supplies. ( + and -, so two converter units, each with a tube ) A full wave V multiplier is preferred for minimal ripple.

It can be refined further to use a resonant scheme, with both a moderately low ratio Ferrite xfmr -and- a moderate ratio cap/diode multiplier in cascade (C multiplier above the xfmr, product of the ratios then ). This allows the leakage inductance of the xfmr to be resonated with the effective series capacitance of the multiplier at the switching frequency. So effectively removing the parasitic series capacitance of the C multiplier and the leakage L of the Ferrite xfmr to give a very high damping factor output. (the Berning scheme suffers the xfmr leakage L at the carrier freq. and then needs N Fdbk around the conversion to fix that, to get V output instead of I output )

------------------------------

The Vector saturating field scheme can be done for electric fields besides magnetic fields. Take two long strips of thin metal with a saturable high permittivity dielectric film between them. (an un-wound capacitor essentially). Wires from each strip at one end (or side) for the capacitor leads. Then wind the elongated capacitor assembly on a large core area Ferrite xfmr core, with a secondary copper wire control winding wound on the core too. Placing HV HF voltage on the copper winding induces voltage along the cap strip length, and through the dielectric, without producing a voltage across the "capacitor". If the voltage along the length of the dielectric is sufficient to saturate the dielectric dipoles, then the capacitance between the strips will fall significantly. So varying the HF voltage controls the capacitance.

Varactor bridges are used for a somewhat similar capacitance modulation effect (but not orthogonal fields ). Too small a capacitance for audio I think.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Tube driving magnetic amp?