I have a small 6 watt custom amp head I bought years ago from an individual on craigslist, and have never had a problem with it until recently. I've had a couple times where it would turn on but not generate any sound, but I believe this was due to the power tube being not seated properly. I recently bought a set of replacement tubes, and today it was working fine when suddenly after a few minutes I heard a quiet pop and hiss then it went totally silent. The only tube I didn't replace yet is the rectifier tube. All tubes light up, the fuse looks find, and I've tried using another speaker cabinet. Any ideas where I should start?

Life expectancy for an ELectrolytic is 10 years service, especially if underrated.

With power off, and AC disconnected, discharge any large caps in the powersupply.

WEAR SAFETY GLASSES WHEN DISCHARGING CAPS.

First visually inspect all electrolytics, looking for bulging or leakage.

If you find anything replace those caps with equal sizes and maybe a higher voltage rating if you have room.

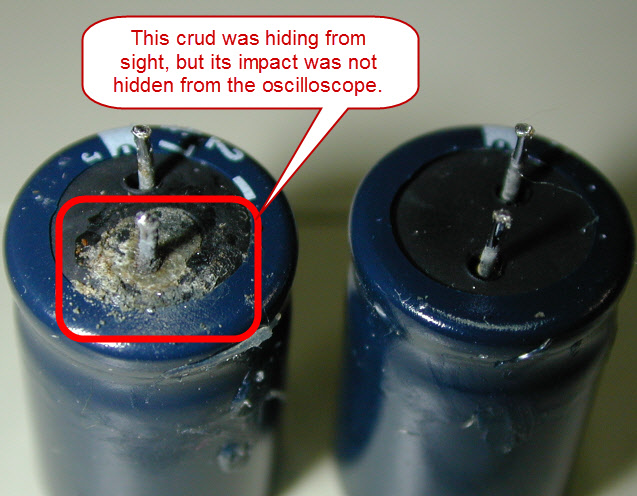

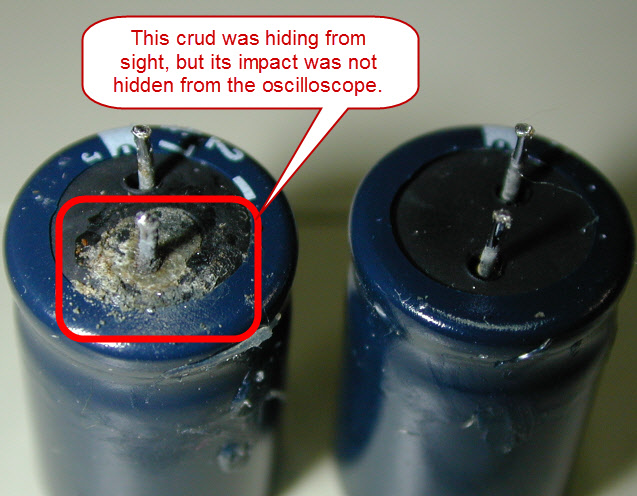

Many modern electrolytics are designed to safely "explode" (split at top):

Old leaky caps

Make a quick sketch of the powersupply circuit, as best you can,

and sort out where you think the B+ and other voltages are and what they should be.

After unplugging all the tubes,

Take a voltmeter (and also take some precautions for not getting electrocuted! like keeping one hand in your pocket),

take some voltage measurements in the power supply,

with the power turned on briefly.

Check the voltage at the center-tap of the output transformer.

Also check the voltages on the plate-pins of the preamp tubes.

Shut power off again quickly, unplug AC chord,

and discharge the large PS capacitors again.

With power off, and AC disconnected, discharge any large caps in the powersupply.

WEAR SAFETY GLASSES WHEN DISCHARGING CAPS.

First visually inspect all electrolytics, looking for bulging or leakage.

If you find anything replace those caps with equal sizes and maybe a higher voltage rating if you have room.

Many modern electrolytics are designed to safely "explode" (split at top):

An externally hosted image should be here but it was not working when we last tested it.

Old leaky caps

An externally hosted image should be here but it was not working when we last tested it.

Make a quick sketch of the powersupply circuit, as best you can,

and sort out where you think the B+ and other voltages are and what they should be.

After unplugging all the tubes,

Take a voltmeter (and also take some precautions for not getting electrocuted! like keeping one hand in your pocket),

take some voltage measurements in the power supply,

with the power turned on briefly.

Check the voltage at the center-tap of the output transformer.

Also check the voltages on the plate-pins of the preamp tubes.

Shut power off again quickly, unplug AC chord,

and discharge the large PS capacitors again.

Take notes, report back.[FONT=Arial, Helvetica, sans-serif]An externally hosted image should be here but it was not working when we last tested it.[SIZE=+1]How To Discharge The High Voltage Capacitor in Microwave Ovens [/SIZE][/FONT]

[FONT=Arial, Helvetica, sans-serif]First Method: The capacitor is discharged by creating a short circuit (direct connection) between the two capacitor terminals and from each terminal to chassis ground (bare metal surface).[/FONT]

[FONT=Arial, Helvetica, sans-serif]

- [FONT=Arial, Helvetica, sans-serif] Do this by touching the blade of an insulated-handled screw driver to one terminal, then slide it toward the other terminal until it makes contact and hold it there for a few seconds. (This can result in a rather startling "pop!")[/FONT]

- [FONT=Arial, Helvetica, sans-serif] Repeat the procedure to create a short between each capacitor terminal and chassis ground.[/FONT]

- [FONT=Arial, Helvetica, sans-serif] If the capacitor has three terminals, use the same procedure to create a short circuit between each terminal and then from each terminal to ground.[/FONT]

- [FONT=Arial, Helvetica, sans-serif] Older Amana-made models (generally those manufactured before 1977) have red, round filter capacitors mounted in the base of the magnetron tube which can also hold a charge. Ground each magnetron terminal by creating a short circuit to chassis ground using the blade of a screwdriver as explained above.[/FONT]

An externally hosted image should be here but it was not working when we last tested it.[/FONT] [FONT=Arial, Helvetica, sans-serif]Although most manufacturers specify the above procedure in their service manuals, some prefer the following alternate method involving the use of a resistor to slow the discharge rate.[/FONT] [FONT=Arial, Helvetica, sans-serif]Alternate Method: As shown in the illustration to the right, attach one end of a 100K - 150K ohm, 25 watt resistor to the bare metal chassis with an alligator clip. Attach the other end of the resistor to the blade of a well insulated screwdriver.[/FONT]

[FONT=Arial, Helvetica, sans-serif]

- [FONT=Arial, Helvetica, sans-serif]Touch the blade of the screwdriver to one of the capacitor terminals and hold it there for a few seconds. Then repeat the procedure for the other terminal.[/FONT]

- [FONT=Arial, Helvetica, sans-serif]To ensure that the capacitor is fully discharged, follow the first method (shown above). [/FONT]

An externally hosted image should be here but it was not working when we last tested it.[/FONT]An externally hosted image should be here but it was not working when we last tested it.[FONT=Arial, Helvetica, sans-serif]Warning - Death on Contact

Never attempt to measure the High Voltage at a magnetron or HV transformer terminals.[/FONT]

[FONT=Arial, Helvetica, sans-serif]An externally hosted image should be here but it was not working when we last tested it.[/FONT]

Last edited:

The above safety posters are wonderful but don't explain the one hand rule (so no electricity crosses your heart) and the never work alone rule. I use a 470-1000 ohm 3 watt or above resistor with leads soldered to 600v wire to discharge caps, amps under 100 Watts usually don't have above 600 V power supplies or caps. I put heat shrink over the resistor- wire terminals. When I take measurements with power on (on amps, not microwaves) I attach a clip lead from P.S. negative (usually chassis) to meter negative, so I only have to use one hand. In case I've forgotten something, read the High Voltage for newbies sticky thread at the top of the tube amp thread. A useful tube amp theory website is aikenamps.com.

After the caps are discharged, the cheapest ones can go bad in 6 years or less. I would just replace them all, freight is a minimum of $7 and the tools will be >$50. ESR checking meters that will check caps up to 10000 uf are $150, so I don't own one. Try to buy 3000 hour rated life or up caps. farnell.com has the cap life in the selector table, other vendors make you download the manufacturers datasheet and read it. Some vendors don't have links to the manufacturers datasheet, and some won't tell you the part number or vendor of the cap. Old stale e-caps are a waste of money, the air has been attacking the rubber seal since the day they were made.

I use old stranded wire dipped in Oatey #5 solder paste to soak up the old solder before removing. Wash the area with a damp paper towel after removal, this stuff makes an acid. I use a Weller WP25 iron with 7/32 screwdriver tip, but if your amp has silver ROHS solder you'll need something hotter, maybe a WP35. Use safety glasses removing solder, it can splash. R***** S***** irons are **** including the solder sucking one that worked three times. Their tin-lead solder was okay, as were their alligator clip leads. You need needle nose pliers, slip joint pliers, a miller wire stripper, a steel pick like Sear has or General Tools, and diagonal cutters. Xcelite or Diamond Tools make the best cutters, if you don't lose things. Mine are 40 years old.

Usually a short time short won't damage a rectifier tube too badly, but they are the ones that are most likely to wear out. 6x4, 5AR4 etc. If you have any semiconductor rectifiers like 1n4007 etc, they can be blown up by a shorted caps. Some designers use low watt resistors as cheap fuses, look for any burned cinders near the transformer.

After the caps are discharged, the cheapest ones can go bad in 6 years or less. I would just replace them all, freight is a minimum of $7 and the tools will be >$50. ESR checking meters that will check caps up to 10000 uf are $150, so I don't own one. Try to buy 3000 hour rated life or up caps. farnell.com has the cap life in the selector table, other vendors make you download the manufacturers datasheet and read it. Some vendors don't have links to the manufacturers datasheet, and some won't tell you the part number or vendor of the cap. Old stale e-caps are a waste of money, the air has been attacking the rubber seal since the day they were made.

I use old stranded wire dipped in Oatey #5 solder paste to soak up the old solder before removing. Wash the area with a damp paper towel after removal, this stuff makes an acid. I use a Weller WP25 iron with 7/32 screwdriver tip, but if your amp has silver ROHS solder you'll need something hotter, maybe a WP35. Use safety glasses removing solder, it can splash. R***** S***** irons are **** including the solder sucking one that worked three times. Their tin-lead solder was okay, as were their alligator clip leads. You need needle nose pliers, slip joint pliers, a miller wire stripper, a steel pick like Sear has or General Tools, and diagonal cutters. Xcelite or Diamond Tools make the best cutters, if you don't lose things. Mine are 40 years old.

Usually a short time short won't damage a rectifier tube too badly, but they are the ones that are most likely to wear out. 6x4, 5AR4 etc. If you have any semiconductor rectifiers like 1n4007 etc, they can be blown up by a shorted caps. Some designers use low watt resistors as cheap fuses, look for any burned cinders near the transformer.

Last edited:

Great details Indianajo.

In the shop at recording studio, we always replace all electrolytic caps on vintage gear as the first step to restoring their function and sound. Old caps go in garbage.

Checking any diodes (maybe just replacing bridge with a higher rating) is good advice too. Power Supply Rectifier tubes should be checked on a tube-checker, before firing up anything.

Don't try to burn in a guitar amp with a variac (this will affect the tube-heaters too, a bad thing).

In the shop at recording studio, we always replace all electrolytic caps on vintage gear as the first step to restoring their function and sound. Old caps go in garbage.

Checking any diodes (maybe just replacing bridge with a higher rating) is good advice too. Power Supply Rectifier tubes should be checked on a tube-checker, before firing up anything.

Don't try to burn in a guitar amp with a variac (this will affect the tube-heaters too, a bad thing).

- Status

- Not open for further replies.