Hello Guys.

I'm trying to fix a peavey PVi 4B powered mixing console (4 channel in 1 powered out). Made in China.

Initially, one power transistor (2SA1943), 2 power resistors (33 ohm/5W) and a voltage regulator (7915, for the preamp section) had gone bad.

I replaced both power transistors (2SA1943 and 2SC5200) with exactly the same type, put 2 new 39 ohm/5W resistors (I couldn't get the 33 ohm ones) and put a new 7915 regulator in place. I checked all other transistors, diodes, resistors, caps, etc and they all seems to be OK.

When I turn it on, the outcoming sound is very low and distorted, as if a transistor is not working. I have to say that I did not replace the driver transistors (C2073 and A1837) since they measured OK on my DVM outside the PCB. At least the power amp doesn't blow up ...

When using the direct output, the preamp section works fine, except for the onboard digital reverb (it works but sounds absolutely nasty. It does not deserve the name "reverb"). I can't find the appropriate words to describe it, other than absolute crap...

I know that I'm missing something. Any help?

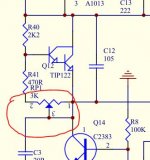

Here is a schematic of this amp. It's not a 100% accurate but that's all I could find.

I'm trying to fix a peavey PVi 4B powered mixing console (4 channel in 1 powered out). Made in China.

Initially, one power transistor (2SA1943), 2 power resistors (33 ohm/5W) and a voltage regulator (7915, for the preamp section) had gone bad.

I replaced both power transistors (2SA1943 and 2SC5200) with exactly the same type, put 2 new 39 ohm/5W resistors (I couldn't get the 33 ohm ones) and put a new 7915 regulator in place. I checked all other transistors, diodes, resistors, caps, etc and they all seems to be OK.

When I turn it on, the outcoming sound is very low and distorted, as if a transistor is not working. I have to say that I did not replace the driver transistors (C2073 and A1837) since they measured OK on my DVM outside the PCB. At least the power amp doesn't blow up ...

When using the direct output, the preamp section works fine, except for the onboard digital reverb (it works but sounds absolutely nasty. It does not deserve the name "reverb"). I can't find the appropriate words to describe it, other than absolute crap...

I know that I'm missing something. Any help?

Here is a schematic of this amp. It's not a 100% accurate but that's all I could find.

Attachments

With 3300 uf rail caps, this must be about a 75 to 100 w powered mixer,

Are you sure the 33 ohm 5 w resistors aren't 0.33 ohm? that is a typical value for an emitter resistor on the output transistor, which often blows with the OT.

When output transistors fail in a power amp, they often take out the drivers, predrivers, and sometimes the input op amp.

Transistor testers at 2 v will not show the damaged parts most times. A Vceo test at 50 v or even 12 v will make a damaged transistor break down. I use a 12v car battery charger, series a 47k resistor, series the low ma scale of the dvm. 12/47k is about 300 microamp. If that much flows from c to e with the base disconnected, then the transistor is not holding off anything. Reverse polarity for pnp.

Warning, voltage above 24 across your heart can stop it. Use clip leads for the test above 24 v. Use no jewelry on hands or neck, 1 v at high current through metal can burn your flesh to charcoal.

Peavey stuff I own sounds very pure after repair. Own 2 PV8 mixers, a PV-4c power amp, a CS800s power amp. Sound like you still have some blown up stuff. If you have a scope, music should look like nice waves, no flat tops. If not, protect a cheap amp input with a voltage clamp and use it as a sound probe. Voltage clamp is .047 uf caps + and -, series 10000 ohm resistors + and -, those connect to two led back to back. Output of that goes to the amp, clamps the signal to 1.2 vac .

Instead of a scope, I fix most things with a 5kohm/v AC voltmeter, analog. Needs a series .047 uf cap to prevent DC from showing up as AC. 2.5 vac is useful for the front end, 20 vac scale useful for the op amp stages. Cheap DVM make up random numbers on music other than 50 and 60 hz. Fluke RMS meter misses any oscillation over 7 khz, is totally not worth the $180 IMHO.

With sound probe or scope or AC voltmeter, look for the first stage where the music from a radio input goes to ****. There your problems are. Sometimes even 50 v .1 uf ceramic supply caps blow open or short due to rail voltage rampaging forwards from the output transistors. Again capacitance testers may not show the problem since they test at 1 to 2 volts. Leakage test at 12 v or higher shows a broken down cap. Of course, resistors you can measure with DVM.

In peavey stuff after 1986? look for punch down blocks and or ribbon cables that have lost contact. Sometimes pushing down on the wire will make them work temporarily. Also, hand built Peaveys from US factories sometimes have bad solder joints that look good, passed visual inspection, but don't connect when cold.

Are you sure the 33 ohm 5 w resistors aren't 0.33 ohm? that is a typical value for an emitter resistor on the output transistor, which often blows with the OT.

When output transistors fail in a power amp, they often take out the drivers, predrivers, and sometimes the input op amp.

Transistor testers at 2 v will not show the damaged parts most times. A Vceo test at 50 v or even 12 v will make a damaged transistor break down. I use a 12v car battery charger, series a 47k resistor, series the low ma scale of the dvm. 12/47k is about 300 microamp. If that much flows from c to e with the base disconnected, then the transistor is not holding off anything. Reverse polarity for pnp.

Warning, voltage above 24 across your heart can stop it. Use clip leads for the test above 24 v. Use no jewelry on hands or neck, 1 v at high current through metal can burn your flesh to charcoal.

Peavey stuff I own sounds very pure after repair. Own 2 PV8 mixers, a PV-4c power amp, a CS800s power amp. Sound like you still have some blown up stuff. If you have a scope, music should look like nice waves, no flat tops. If not, protect a cheap amp input with a voltage clamp and use it as a sound probe. Voltage clamp is .047 uf caps + and -, series 10000 ohm resistors + and -, those connect to two led back to back. Output of that goes to the amp, clamps the signal to 1.2 vac .

Instead of a scope, I fix most things with a 5kohm/v AC voltmeter, analog. Needs a series .047 uf cap to prevent DC from showing up as AC. 2.5 vac is useful for the front end, 20 vac scale useful for the op amp stages. Cheap DVM make up random numbers on music other than 50 and 60 hz. Fluke RMS meter misses any oscillation over 7 khz, is totally not worth the $180 IMHO.

With sound probe or scope or AC voltmeter, look for the first stage where the music from a radio input goes to ****. There your problems are. Sometimes even 50 v .1 uf ceramic supply caps blow open or short due to rail voltage rampaging forwards from the output transistors. Again capacitance testers may not show the problem since they test at 1 to 2 volts. Leakage test at 12 v or higher shows a broken down cap. Of course, resistors you can measure with DVM.

In peavey stuff after 1986? look for punch down blocks and or ribbon cables that have lost contact. Sometimes pushing down on the wire will make them work temporarily. Also, hand built Peaveys from US factories sometimes have bad solder joints that look good, passed visual inspection, but don't connect when cold.

Last edited:

Okay, first, lets be sure you have the necessary test gear... You will need a multimeter for voltage checks and either a small amplifier or an oscilloscope for signal checks.

(You can easily make an audio probe for an amplifier by putting a .1uf 100v cap and 10k resistor in series with the signal lead.)

Some preliminary checks...

1) Recheck all your work so far. Pay special attention to the orientation of parts

and the quality of solder work. I've been at this a long time and I still mess up occasionally.

2) check the cables and connectors to make sure you have clean and proper connections throughout.

3) Check all the power rails V+ V- etc. and make sure they are correct.

4) Check those two resistors you changed (R44 and R45 on sheet PV4B_5) 33 ohms doesn't make much sense in that position. They are marked as R33 which actually means 0.33 ohms. (It most correctly should have said 0R33)

If all that is good...

I'm guessing the low output is from the power amplifier used for speakers?

So you need to first check for DC offsets at the amplifier's output... R47 to ground on page PV4B_5. This should read no more than a few millivolts.

If that's all good, check to see if the protection relay is pulling in a few seconds after you turn it on. You should hear it click.

If all this is good, you need to test the Amp IN (J5 pin 4 or R31 on sheet PV4B_5) ... in this case you need to either hear or see a clean signal.

If the amp IN is clean we know the problem is in the power amp. If it's not we need to look at the rest of the mixer sections.

Let me know how you make out, please...

(You can easily make an audio probe for an amplifier by putting a .1uf 100v cap and 10k resistor in series with the signal lead.)

Some preliminary checks...

1) Recheck all your work so far. Pay special attention to the orientation of parts

and the quality of solder work. I've been at this a long time and I still mess up occasionally.

2) check the cables and connectors to make sure you have clean and proper connections throughout.

3) Check all the power rails V+ V- etc. and make sure they are correct.

4) Check those two resistors you changed (R44 and R45 on sheet PV4B_5) 33 ohms doesn't make much sense in that position. They are marked as R33 which actually means 0.33 ohms. (It most correctly should have said 0R33)

If all that is good...

I'm guessing the low output is from the power amplifier used for speakers?

So you need to first check for DC offsets at the amplifier's output... R47 to ground on page PV4B_5. This should read no more than a few millivolts.

If that's all good, check to see if the protection relay is pulling in a few seconds after you turn it on. You should hear it click.

If all this is good, you need to test the Amp IN (J5 pin 4 or R31 on sheet PV4B_5) ... in this case you need to either hear or see a clean signal.

If the amp IN is clean we know the problem is in the power amp. If it's not we need to look at the rest of the mixer sections.

Let me know how you make out, please...

Last edited:

I changed back R44 / R45 to the original 0.33 ohm resistors which were actually working. I checked all soldering and connectors. Then I plugged it in and listened...

I used an instrument cable and touched the tip (this usually works just fine). Then I turned the main volume pot to 12 o'clock. For a very brief moment I heard sound coming out of my speaker box with just the volume that one would expect at main vol knob half way up. Then there was silence.

I bought a pair of the 2SC5200 and 2SA1943 transistors online at half the price as in other stores. Pirate transistors, maybe that's one problem.

And I should have changed the drivers as well...

I'll give it another shot.

I used an instrument cable and touched the tip (this usually works just fine). Then I turned the main volume pot to 12 o'clock. For a very brief moment I heard sound coming out of my speaker box with just the volume that one would expect at main vol knob half way up. Then there was silence.

I bought a pair of the 2SC5200 and 2SA1943 transistors online at half the price as in other stores. Pirate transistors, maybe that's one problem.

And I should have changed the drivers as well...

I'll give it another shot.

I'll give it another shot.

Rather than changing parts more or less at random, perhaps a bit of directed troubleshooting is in order to isolate the exact failure.

Do you have a multimeter?

Alright then ... start with a voltage check on all the supply rails ... check DC voltage, then on the AC scale check for ripple. I suspect they're pretty much OK but it can't hurt to be sure.

Looking at sheet PV4B_5 (the power amplifier)...

No speakers, no inputs, all levels at 0.

All readings with respect to ground.

Take a reading at R47 ... this is your DC offset. It should read almost 0, just a few milivolts. Any big offsets here (more than a volt) indicate a problem in the amplifier.

If that is okay, take a reading at the anode of D16... It should be near 0, if not, this will tell us if the amp is in protection mode.

Let me know what you find and we'll move to the next step...

Looking at sheet PV4B_5 (the power amplifier)...

No speakers, no inputs, all levels at 0.

All readings with respect to ground.

Take a reading at R47 ... this is your DC offset. It should read almost 0, just a few milivolts. Any big offsets here (more than a volt) indicate a problem in the amplifier.

If that is okay, take a reading at the anode of D16... It should be near 0, if not, this will tell us if the amp is in protection mode.

Let me know what you find and we'll move to the next step...

Last edited:

Thanks, Douglas.

I will do these procedures, as soon as I get a new 2SA1943...

Okey dokey ... You mentioned that you've changed both Q9 and Q16 ... you might want to consider getting a new set.

I don't know where you've been buying your parts but I suggest you go the "trusted sources" route. It will be a bit more expensive than eBay or Ali but at least you know you're getting good parts.

I don't have a picture of the inside of that amp, but I imagine those transistors are on heat sinks, so be sure to wipe up the old white grease and put some fresh stuff in when you put in the new parts.

Buying counterfeit power transistors will just destroy more parts in your amp when they inevitable fail, Mouser, Digikey, Farnell/Element14 etc, the trusted sources are the place to go. And if you need a transistor, get at least one spare too, cheaper in the long run, and you can keep them for future repairs.

OK. I will get a new pair of MOSFETs and a pair of drivers from a trusted source. I'm buying all my electronics parts locally in Caracas / Venezuela. Usually they offer their stuff as the best of the best, and when you ask whether the parts are original or pirated merchandise, the get cranky...

But there are a few stores that are trustworthy.

But there are a few stores that are trustworthy.

Buying counterfeit power transistors will just destroy more parts in your amp when they inevitable fail.

Yeah ... in my shop we used to call it "Bargain Backfire"... 🙂

Hello, I'm back.

I installed a new pair of 2SA1943/2SC5200 MOSFETs and A1837/C2073 drivers.

Then I proceeded as Douglas suggested:

With the amp powered, power rails measure +45.5 / -45.2 VDC and +14.8/-14.7VDC, respectively.

I wasn't able to find R47 on the PCB, since there are no markings for components, just there values, but since it is in parallel to coil L1, I took the offset reading on this coil. It reads 4.0mV when no speaker is connected and 8.1mV with just a plug inserted into the output connector.

Relay does activate after afew seconds.

For the next step "checking if power amp in is clean" I would have to insert a speaker.

Is this correct? I don't have any scope.

I installed a new pair of 2SA1943/2SC5200 MOSFETs and A1837/C2073 drivers.

Then I proceeded as Douglas suggested:

With the amp powered, power rails measure +45.5 / -45.2 VDC and +14.8/-14.7VDC, respectively.

I wasn't able to find R47 on the PCB, since there are no markings for components, just there values, but since it is in parallel to coil L1, I took the offset reading on this coil. It reads 4.0mV when no speaker is connected and 8.1mV with just a plug inserted into the output connector.

Relay does activate after afew seconds.

For the next step "checking if power amp in is clean" I would have to insert a speaker.

Is this correct? I don't have any scope.

I think I mentioned before that schematic and real PCB assembly do not match entirely.

For example, on the schematic +/-15V is regulated by Q18 TIP122 and Q19 TIP127, on the real deal they use 7815 and 7915 regulators.

For example, on the schematic +/-15V is regulated by Q18 TIP122 and Q19 TIP127, on the real deal they use 7815 and 7915 regulators.

For the next step "checking if power amp in is clean" I would have to insert a speaker. Is this correct? I don't have any scope.

With no scope you don't really have much choice. There's no harm in hooking up a speaker... but until we are sure it's ok, keep the volume very low. This isn't the time for a full power test.

The final step is the bias setting... You want just a few milliamps of current in the output stages with no signal coming in. This prevents increasing distortion at lower levels, called a "Crossover Notch". Sadly there is no spec for this so we're going to keep it very conservative...

No inputs, no speaker, volume at zero...

Connect your meter across one of the 0R33 resistors (R44 or R45).

Dc voltage scale on your meter.

Now turn on the amplifier and get a voltage reading... it should be in the area of 25 millivolts.

Now check everything to be sure it's running nice and cool. Then let the amp idle for an hour or so and recheck your reading... it should be stable.

If all that is ok, you're done.

If you are getting less than 20 or more than 30 millivolts, you will need to adjust RP1 for 25mv. then repeat the set and check a couple of times to be sure it's remaining stable.

Last edited:

With amp on, the anode side of D16 it reads 791 mV (cathode side is 14.77V). R44 (0R33) reads 16mV/116mV, R45 reads -7.8mV/-97mV.

The 25 mV are not present.

What do you suggest now?

The 25 mV are not present.

What do you suggest now?

With amp on, the anode side of D16 it reads 791 mV (cathode side is 14.77V). R44 (0R33) reads 16mV/116mV, R45 reads -7.8mV/-97mV.

The 25 mV are not present.

What do you suggest now?

Ok, given that the amp is now out of protection, we can stop worrying about D16 and it's buddies. That was just a check to see if it thought it was pulling in the relay or not.

For the measurement on R44 or R45 ... this is not a to ground reading. It is a reading taken directly across the resistor itself. What we are doing is checking current by reading voltage.

For example...

If we have a 10 ohm resistor with 6 volts across it. Ohm's law tells us that I = E / R == 6 / 10 == .66 amps is flowing.

Conversely in an adjustment scenario if we want 0.6 amps we can calculate that we should see E = I x R == 0.6 x 10 == 6 volts.

So, in this case we want some small current flowing something in the order of 8 to 10 milliamps we can calculate E = I x R == 0.010 x 0.33 == 33millivolts across that resistor.

To be a bit conservative without the service manual to guide us we go for 20 to 30 with an ideal about 25 millivolts... read directly across the resistor leads. We sell it a bit short, because we don't actually know the design parameters.

If you are outside this range there is a trimpot on the board, RP1, that should let you adjust it.

Was that confusing enough? 😀

Attachments

Last edited:

I measured across each resistor R44 and R45. It kept slowly rising (same reading on both transistors) and when it hit 100 mV i turned the amp off.

Should I still try to adjust with the trimpot? Or should I check something else before I adjust?

Should I still try to adjust with the trimpot? Or should I check something else before I adjust?

I measured across each resistor R44 and R45. It kept slowly rising (same reading on both transistors) and when it hit 100 mV i turned the amp off.

Should I still try to adjust with the trimpot? Or should I check something else before I adjust?

At 100 mv a0r33 resistor is passing : .1 / .33 == .30 amps ... that's 300ma way over our goal of 10 ma.

Nothing personal here, just being thorough...

Were things getting warm?

How often did you adjust the pot?

If you adjust it now, will that voltage go down?

Try cleaning the trimmer with a bit of rubbing alcohol, spin it end to end a few times and then let it dry... then try it again.

When you put in the new outputs did you use heat sink grease?

Are you sure the new outputs are correctly mounted on the heatsink?

Check the new parts you put in... are they hot?

How about the drivers right before them in the circuit?

What is the DC offset doing, is it drifting too?

Some parts to check ...

D7, D8, D9 and D10 ... make sure they are still diodes

Q7 and Q14 ... make sure they're not heating and not shorted.

Q12 ... Monitor the voltage from it's collector to emitter and see if it's creeping up and be sure it's not heating.

Check the voltages across r26 and r27 ... they should be stable and pretty much equal.

Tests like this should really be done on reduced voltage rather than risk frying it again... I don't suppose you have a variac or dimbulb tester, do you?

Last edited:

Hello Again.

All of the transistors were getting warm but not extremely hoy.

I did not adjust the pot, yet. Since the reading is 4 times the expected value, I figured that something else must be wrong.

This is a sealed multiturn trimpot, with a little screw on top. I don't think I can apply alcohol to the inside (tried this before on other sealed pots with little hole in it. didn't work)

I did use heatsink grease, and all transistors are mounted correctly on the heatsink.

I'll give it another inspection later today and keep you informed...

All of the transistors were getting warm but not extremely hoy.

I did not adjust the pot, yet. Since the reading is 4 times the expected value, I figured that something else must be wrong.

This is a sealed multiturn trimpot, with a little screw on top. I don't think I can apply alcohol to the inside (tried this before on other sealed pots with little hole in it. didn't work)

I did use heatsink grease, and all transistors are mounted correctly on the heatsink.

I'll give it another inspection later today and keep you informed...

Attachments

- Home

- Amplifiers

- Solid State

- Trying to fix a peavey PVi 4B