I'll preface this with saying that I'm reasonably new at this, and I'm doing the best I can with a multimeter and what little knowledge I have. But essentially I'm troubleshooting an Elekit 8600 where one of the 300B tubes is consistently running hotter than the other. This is a problem that has (maybe) been happening since I built this amp 6 years ago, but the voltages at a few test points fell within normal fluctuation ranges though a few were a little high, but the amp played fine, and I didn't really focus on it.

That said, I started having issues with distortion, and a channel cutting out occasionally (after 4-5 years), until finally one channel would pop and stop altogether. I would swap tubes from side to side, but ultimately it never seemed to change the performance, and once one of the tubes (I think) became damaged, tube swapping didn't help because if it's the tube AND the amp, it becomes difficult to diagnose. Finally, I just replaced the two 300B tubes, (not the ECC82s or the ECC83) with a matched set. and put them on the amp. I turned on the amp and it sounded OK-ished but I noticed one tube seemed a lot brighter. After a minute or so of playing, one tube was significantly hotter than the other (one was measuring 86F and the other was 136F). I didn't let it keep running because I didn't want to damage the tubes, so I shut it off.

So here are the actions I've taken:

1. Initially when I had the problem, I reflowed the connections for the tube sockets and visually inspected the PCB, problem seemed to be better, but after a while persisted, honestly the problems were intermittent anyway, so not even sure this had an impact

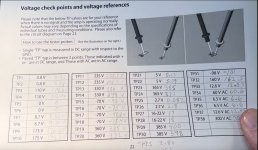

2. Retested all test points. All voltages were fine, except for two fairly close to the channel - these were unusually high, but fell within the 10% range of acceptable according to instructions, but by then, one of my tubes were probably fried so I am not sure of the cause

3. Purchased a matched set of new 300Bs - but in my first try one channel got so much hotter than the other, I shut it off

4. Taken apart the amp, to visually reinspect to make sure that I put it together in the first place, resistors, transistors all in the proper place and orientation.

5. I also visually inspected solder joints - and started doing some continuity tests, but honestly don't know how to do this effectively. I have a Fluke 87 Multimeter which I think is a pretty decent machine, but when it came to resistors, it was hit or miss whether the continuity was registering.

6. I took a multimeter and tested each resistor for the correct value. I realize that IN A PCB, the circuit is going to impact how these measured, and some of the resistors seemed way off, but when they were way off, they were off in pairs, meaning the readings were similar channel to channel - which seems like that means they're correct

I've reached out to the local Elekit partner, and he's working to help out, but honestly, I'd love to learn how to understand this a bit better, and I want to see if there are any other common sense checks I've left out. So here are some questions:

1. How can I test, or should I just replace the ECC82s and ECC83 in the amp?

2. Aside from visually inspecting solder joints (they all look fine) - what else can I do to test components here? I have the schematic but would love directionally some idea of potential areas to chase.

3. Can anyone share a good PCB troubleshooting 101 I can watch/read?

4. What other potentially silly or simple thing am I missing here? Could there be some unwanted issue with any connections downstream? Speaker polarity? Pre-amp?

That said, I started having issues with distortion, and a channel cutting out occasionally (after 4-5 years), until finally one channel would pop and stop altogether. I would swap tubes from side to side, but ultimately it never seemed to change the performance, and once one of the tubes (I think) became damaged, tube swapping didn't help because if it's the tube AND the amp, it becomes difficult to diagnose. Finally, I just replaced the two 300B tubes, (not the ECC82s or the ECC83) with a matched set. and put them on the amp. I turned on the amp and it sounded OK-ished but I noticed one tube seemed a lot brighter. After a minute or so of playing, one tube was significantly hotter than the other (one was measuring 86F and the other was 136F). I didn't let it keep running because I didn't want to damage the tubes, so I shut it off.

So here are the actions I've taken:

1. Initially when I had the problem, I reflowed the connections for the tube sockets and visually inspected the PCB, problem seemed to be better, but after a while persisted, honestly the problems were intermittent anyway, so not even sure this had an impact

2. Retested all test points. All voltages were fine, except for two fairly close to the channel - these were unusually high, but fell within the 10% range of acceptable according to instructions, but by then, one of my tubes were probably fried so I am not sure of the cause

3. Purchased a matched set of new 300Bs - but in my first try one channel got so much hotter than the other, I shut it off

4. Taken apart the amp, to visually reinspect to make sure that I put it together in the first place, resistors, transistors all in the proper place and orientation.

5. I also visually inspected solder joints - and started doing some continuity tests, but honestly don't know how to do this effectively. I have a Fluke 87 Multimeter which I think is a pretty decent machine, but when it came to resistors, it was hit or miss whether the continuity was registering.

6. I took a multimeter and tested each resistor for the correct value. I realize that IN A PCB, the circuit is going to impact how these measured, and some of the resistors seemed way off, but when they were way off, they were off in pairs, meaning the readings were similar channel to channel - which seems like that means they're correct

I've reached out to the local Elekit partner, and he's working to help out, but honestly, I'd love to learn how to understand this a bit better, and I want to see if there are any other common sense checks I've left out. So here are some questions:

1. How can I test, or should I just replace the ECC82s and ECC83 in the amp?

2. Aside from visually inspecting solder joints (they all look fine) - what else can I do to test components here? I have the schematic but would love directionally some idea of potential areas to chase.

3. Can anyone share a good PCB troubleshooting 101 I can watch/read?

4. What other potentially silly or simple thing am I missing here? Could there be some unwanted issue with any connections downstream? Speaker polarity? Pre-amp?

It's always best practice to include a schematic, so folk will have somewhere to start.

All good fortune,

Chris

All good fortune,

Chris

Have they found some new and as yet undiscovered secret to valve amplification?

I would suspect an issue with the autobias regulator circuit. Continuing to buy/swap tubes probably won't help.

You'll want to ask Victor if this is ok before posting anything.Is it kosher to share the schematic, it being a kit? I don't want to share anything proprietary?

+1.I would suspect an issue with the autobias regulator circuit.

jeff

When Victor says 'no' then he should back it up by helping this poor guy out directly. Otherwise post the schematic. I agree with Hornbeck - nothing new in single ended 300b land since 1969... This kit is not pricy so it could easily be a regulator.You'll want to ask Victor if this is ok before posting anything.

But - People forget that one way a tube can overheat quickly is to apply the wrong heater voltage, which is a quick way to destroy your pricy 300b.

Seems like I'm stuck a little between a rock and a hard place - I'll reach out to Victor, but in the past he's mentioned not to post the manual or instructions online, I have a paper copy. On the one hand, Victor has been pretty supportive and responsive. On the other, it sounds like my options are potentially shipping it overseas to get it corrected, posting the schematic anyway, or sitting at home with a 50 lb brick I've invested a fair amount of money and time in.

While I wait for his response, I'm looking at the schematic, and nothing in particular is being called out as the bias correction, but there's a section called "Repple Filter". I won't post the schematic unless Victor says it's OK - but I did find another thread with a section about this, I don't know if the portion of the schematic is related to the bias or not : https://www.diyaudio.com/community/threads/tu-8600-voltage-check.338569/

While I wait for his response, I'm looking at the schematic, and nothing in particular is being called out as the bias correction, but there's a section called "Repple Filter". I won't post the schematic unless Victor says it's OK - but I did find another thread with a section about this, I don't know if the portion of the schematic is related to the bias or not : https://www.diyaudio.com/community/threads/tu-8600-voltage-check.338569/

I see that Victor - vkung is a member here too. He even has a sub-forum: https://www.diyaudio.com/community/forums/elekit.134/

I would post the problem you are having THERE so he can address it ASAP.

Seriously, there should be no need to ship it overseas or to Vancouver. If you are really lost, you should be able to just remove the circuit board and ship it to him so he can fix it. You built it as a kit right? This should be possible...

OR he can tell you where to measure some reference voltages, to tell which regulator needs replacing, or maybe a coupling cap has gone, etc.

Who knows, maybe he will write a response here in this forum... but he might not even be aware of this thread yet.

I would post the problem you are having THERE so he can address it ASAP.

Seriously, there should be no need to ship it overseas or to Vancouver. If you are really lost, you should be able to just remove the circuit board and ship it to him so he can fix it. You built it as a kit right? This should be possible...

OR he can tell you where to measure some reference voltages, to tell which regulator needs replacing, or maybe a coupling cap has gone, etc.

Who knows, maybe he will write a response here in this forum... but he might not even be aware of this thread yet.

Last edited:

The Elekit 300B employs self bias with 810 ohm resistor at cathode. Please measure the voltage at cathode and grid relative to ground. Then, we may able to find the cause of the problem.

Thanks @soulmerchant ive been talking to Victor - but even though im sure hes much more technical than me - I thought the collective brain here might be able to clue me into something I’ve been missing.

@kmtang thanks for digging that up. I assume I need to measure the voltage with the tubes in and since these are new I don’t want to damage them. I’ll see if I can dig up the old ones.

@kmtang thanks for digging that up. I assume I need to measure the voltage with the tubes in and since these are new I don’t want to damage them. I’ll see if I can dig up the old ones.

He’s going to sort it one way or another. I’ll say this for Victor, he’s extremely responsive.

Honestly I sort of wanted to fix it myself so I could understand it better but without being able to share the circuit diagram it’s going to be rough.

I guess I’ll have to build my own next?

Honestly I sort of wanted to fix it myself so I could understand it better but without being able to share the circuit diagram it’s going to be rough.

I guess I’ll have to build my own next?

- Home

- Amplifiers

- Tubes / Valves

- Troubleshooting one Hot Tube 300B