First, you should know:

I am a seafarer and I spend fully half of my adult life out at sea. I'd like to say it's just a job, but it really does qualify as a life.

Second thing: I built a powered speaker system to suit my job and I'll tell you the things it needed to achieve in order to even make it aboard a ship with me.

The completed package.

The completed package.

More later.

I am a seafarer and I spend fully half of my adult life out at sea. I'd like to say it's just a job, but it really does qualify as a life.

Second thing: I built a powered speaker system to suit my job and I'll tell you the things it needed to achieve in order to even make it aboard a ship with me.

- Minimum weight: check in luggage has weight limits if you aren't filthy rich. I think the whole setup (2 speakers, MiniDSP Flex & cables) is around 25lbs.

- Small box dimensions: keeping things small is actually a good way to keep weight down as well...less wood, less weight...and Small box means small suitcase witch might also weigh less.

- Nothing stands proud of the box: it's soo much easier to protect the drive units if the surrounds or domes aren't sticking out into harms way. Just tape a protective piece of cardboard over delicate drivers and done!

- Wide bandwidth at the expense of SPL: staterooms aboard ship are tiny so no need to get crazy loud....but I still like bass.

More later.

If you haven't heard of the Reference Minis by forum member Bcodemz, you should check it out, it was a big inspiration for this project even though my creation has none of the features that make his project special aside from small size.

https://www.diyaudio.com/community/...the-reference-mini-post-mortem-thread.340260/

Anyway the parts list is as follows:

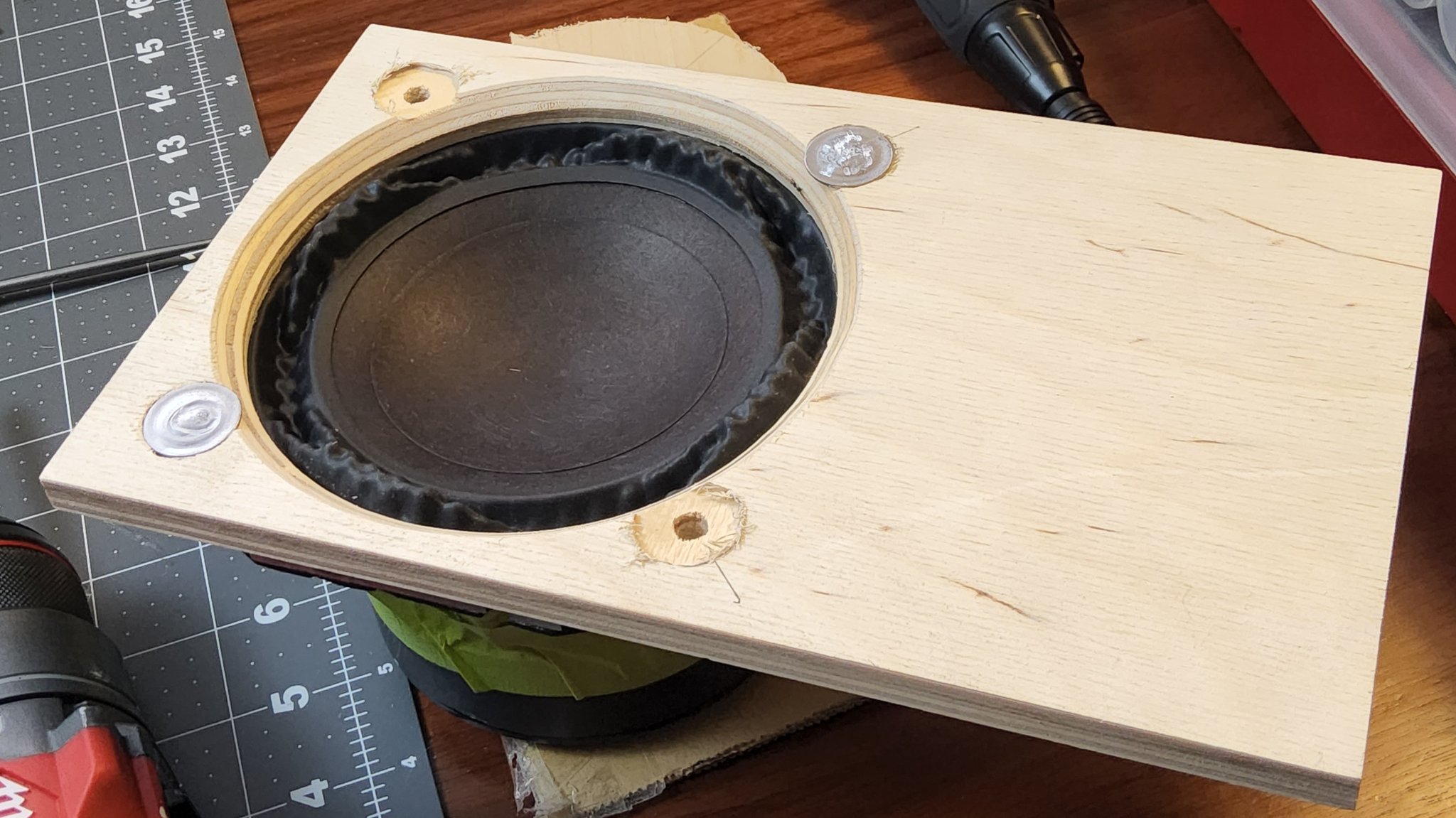

I made a jig to lop off the corners of the drivers and also punch two extra holes in the woofer frame to make it a normal 4 hole setup. Be sure to tape off the woofer perfectly to avoid metal crumbs from getting in the motor!

Woofer mountings where achieved with PE hurricane nuts with tig welded studs.

Woofer mountings where achieved with PE hurricane nuts with tig welded studs.

3/8" front baffle was barely counter sunk for the hurricane studs.

3/8" front baffle was barely counter sunk for the hurricane studs.

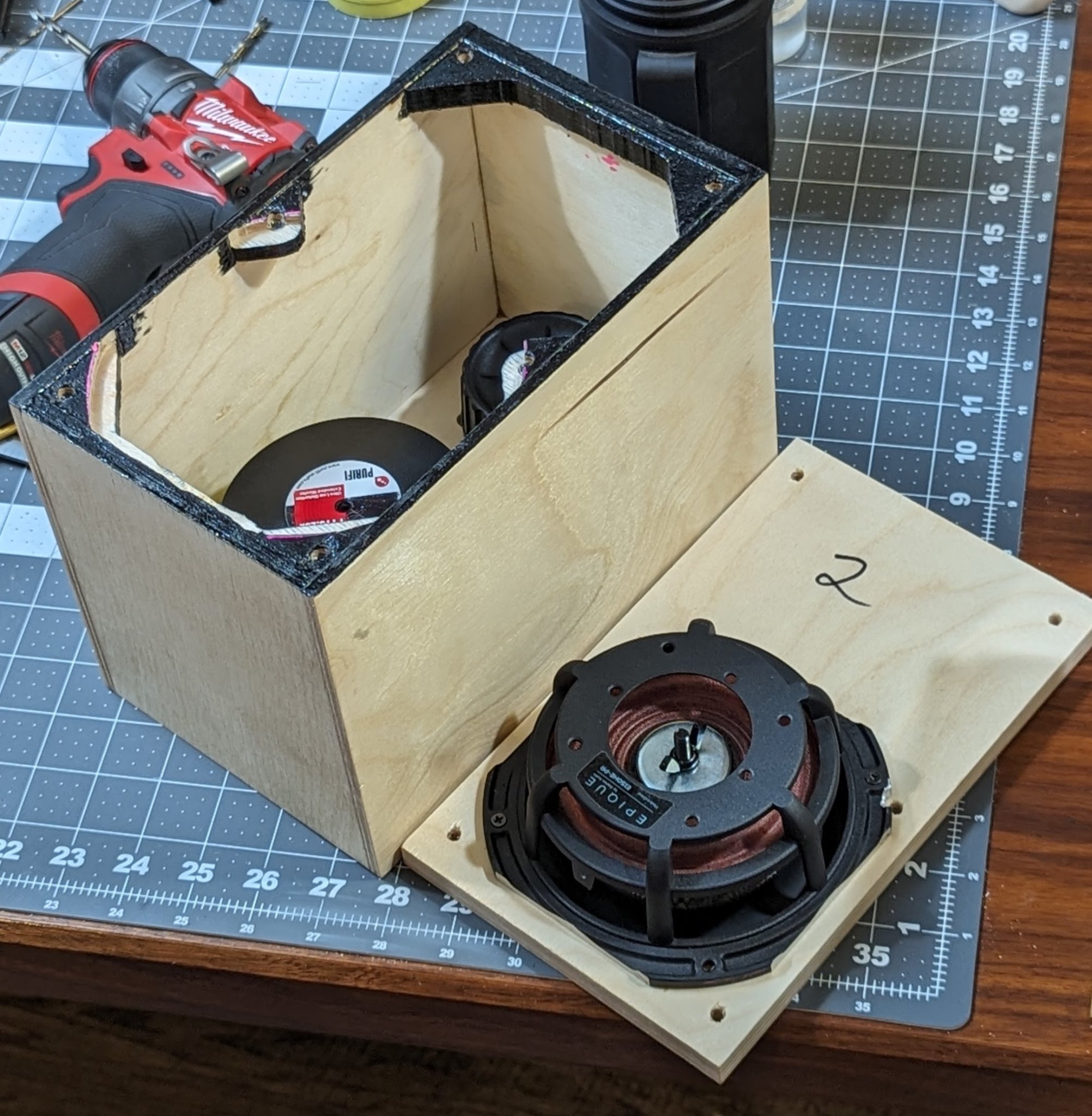

Box 90% structurally finished: rear baffle is 1/2" thick...top, bottom & front baffle are 3/8" thick and side are 1/4"

Box 90% structurally finished: rear baffle is 1/2" thick...top, bottom & front baffle are 3/8" thick and side are 1/4"

More to come

https://www.diyaudio.com/community/...the-reference-mini-post-mortem-thread.340260/

Anyway the parts list is as follows:

- Purifi 5.25 4ohm woofers

- Seas DXT tweeters

- Dayton Epique 5.25 passive radiators

- ICEpower 170w (4ohms) amps, two per speaker.

- Minidsp Flex balanced

- Loads of small bits I don't have the energy to list...unless somebody gets very interested.

I made a jig to lop off the corners of the drivers and also punch two extra holes in the woofer frame to make it a normal 4 hole setup. Be sure to tape off the woofer perfectly to avoid metal crumbs from getting in the motor!

More to come

The rear baffle has a single sheet of 1/16" PSA closed cell foam gasket to seal everything. Also note wires can be easily disconnected for service or mods.

More later.

Super easy to pack!

I'm actually aboard my ship now and have been for nearly two months (I'm in port, so I have internet).

Fun facts:

1. Active crossovers are soo easy it feels like cheating.

2. Crossover is set to 1200hz with 48db/Oct because why not.

3. weight is around 9lbs per speaker.

4. Front baffle and top & bottom are 3/8" thick, sides are 1/4" and rear is 1/2" to keep the PR surround flush. (Repeating myself

5. H=9-3/4" D=7-3/8" W=6"

6. Lost the measurements but no matter, ill have to redo them because I think more tuning is in order.

Final thoughts: these are very intelligible, clean and have amazing vertical off axis sound. Bass output also exceeds expectations for a desktop speaker. Im pretty sure they have more potential.

Thank you for reading and don't be shy about questions.

Those speakers look incredible, and I’m sure the amps will be a nice match.

What will be your source?

One thing I would fortify would be the vhb attachment, that adhesive isn’t meant for porous surfaces, and hot melt will release as it absorbs moisture in fairly short time on nearly anything but paper/fabric.

What will be your source?

One thing I would fortify would be the vhb attachment, that adhesive isn’t meant for porous surfaces, and hot melt will release as it absorbs moisture in fairly short time on nearly anything but paper/fabric.

Will definetely be following the thread with interest if you decide to update.

In the meantime how low would you say that these go? I've been thinking about making some small desktop speakers and would really like for them to go as low as possible. I'm trying to decide if going the DSP route is best for small enclosures with nice bass.

In the meantime how low would you say that these go? I've been thinking about making some small desktop speakers and would really like for them to go as low as possible. I'm trying to decide if going the DSP route is best for small enclosures with nice bass.

I have set them up with a huge amount of LF boost (16db?) at 30Hz and it is shocking how amazing they sound at those frequencies...and how powerful the output is if you stay reasonably close to them (let's say within three meters). Honestly, it's a little unnecessary, I've tried much less boost (7db) and found the output down to 30hz is still very good for movies and such. The fact that the MiniDSP Flex has presets is really helpful to try new settings even without measurements.Will definetely be following the thread with interest if you decide to update.

In the meantime how low would you say that these go? I've been thinking about making some small desktop speakers and would really like for them to go as low as possible. I'm trying to decide if going the DSP route is best for small enclosures with nice bass.

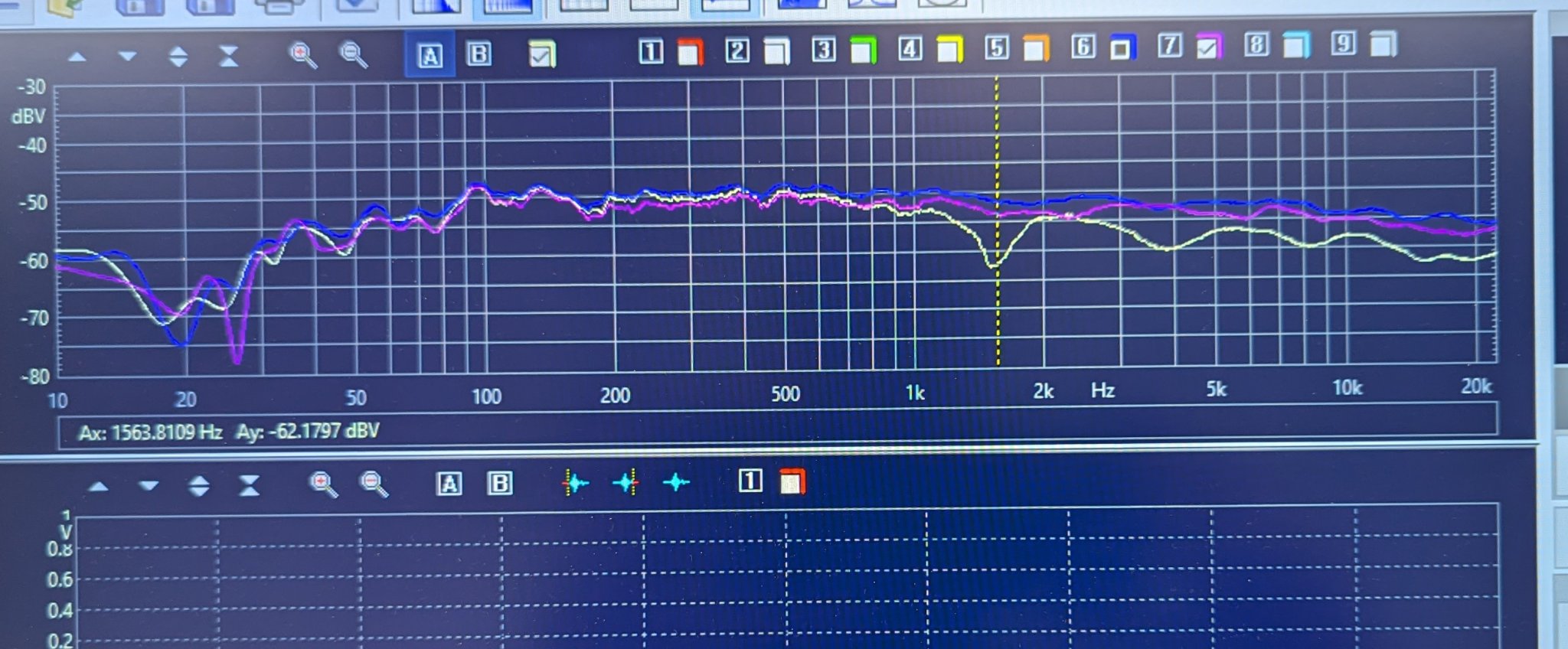

Measurements are in!

The above is horizontal measurements taken at 0, 22.5, 45, and 77.5 degrees.

The above is horizontal measurements taken at 0, 22.5, 45, and 77.5 degrees.

Vertical measurements taken at 0, 22.5, and -22.5 degrees. The large dips are occurring on the below axis measure, so perhaps not too terrible.

Vertical measurements taken at 0, 22.5, and -22.5 degrees. The large dips are occurring on the below axis measure, so perhaps not too terrible.

And here is the rig. I'm using Clio Pocket.

And here is the rig. I'm using Clio Pocket.

Thanks mate! It's been lots of fun listening to these little guys. Just a couple minor improvements to go...I don't know how I missed this thread when it first went up... Great build, and great design!

- Home

- Loudspeakers

- Multi-Way

- Travel speaker build