…Ceramica....

A good example of braces going the least effective way. Given it is a translam, these will have minimum benefit.

dave

Attachments

Where?

I can't find any on the link, and I can't see any on this thread either from people who have never done a translam build. I have. Dave has. Wesayso has. Cal (I believe) has. So I'm not quite sure who you're referring to? It would be worth seeing their comments so they can be assessed, although in fairness to whoever they are, it isn't actually necessary to build an enclosure using this approach to assess its basic mechanical features characteristics.

I can't find any on the link, and I can't see any on this thread either from people who have never done a translam build. I have. Dave has. Wesayso has. Cal (I believe) has. So I'm not quite sure who you're referring to? It would be worth seeing their comments so they can be assessed, although in fairness to whoever they are, it isn't actually necessary to build an enclosure using this approach to assess its basic mechanical features characteristics.There are gray sharks, yellow fin tuna, red snapper and bluefish there. Not to mention the assortment of sea life on the bottom and perching birds in the upper right.

No new wood was used in that wall.

I like it. Oh yes indeed, I like it. 🙂

Makes me think I should do something with the garage wall...

Scott, he may have been referring to the Audio Circle forum when speaking of comments from virgins.

I think the advantage of a laminate build is you really only need a saw, a jig saw and a sander for unusual shapes.

If you can use bendy ply or similar, you don't need to waste all that wood.

I did mine just as an experiment.

I love to play with new things and after about 50 pairs of speakers that was the right thing to do.

If you can use bendy ply or similar, you don't need to waste all that wood.

I did mine just as an experiment.

I love to play with new things and after about 50 pairs of speakers that was the right thing to do.

Ah, that would be it. I only had a look at the direct link to the images etc., but I didn't look any further.

I'm still lousy at building things though. Colin has banned me from all future use of woodworking tools, for my health and that of others. 😉

I'm still lousy at building things though. Colin has banned me from all future use of woodworking tools, for my health and that of others. 😉

...If you can use bendy ply or similar, you don't need to waste all that wood...

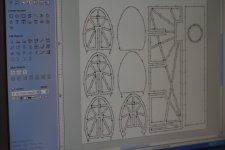

A lot of time went into these (mostly by chris):

But alot of the work was reused. The curved bit was also used to make a set of curved back Pensil7.3 (before they were veneered and finished.

dave

A good example of braces going the least effective way. Given it is a translam, these will have minimum benefit.

dave

Most definitely no problems related to bracing. In the areas of most concern the cabinet is very thick and sounded by sand filled voids. They are also made of moisture resistant HDF. They must weigh More than 100lbs each.

Most definitely no problems related to bracing. In the areas of most concern the cabinet is very thick and sounded by sand filled voids. They are also made of moisture resistant HDF. They must weigh More than 100lbs each.

So brute force instead of finesse. With the sand filled thick walls the brace sare probably doing little.

dave

Just to be clear, neither of the designs Dave posted photos of were translams. While CNC routing was used to machine a few curved rib components, the curved panels were all vacuum bag formed rubber ply - very rigid when laminated 3 layers thick with yellow carpenters glue (Titebond 2, or Dural equivalent, IIRC). Even if we could have convinced ourselves of the merit of wasting that much material on a proof of. Inception build, the CNC time on the commercial machine at work would have cost dearly.

No matter how you go about it, CCM - curves cost money.

No matter how you go about it, CCM - curves cost money.

Whilst there's no denying translam builds can be expensive in terms of wasted material (although not necessarily so as Wesayso has demonstrated), they are an attractive option for anyone wanting to build a curved cabinet without access to tools or the required skills.

One of our customers has just built one which is featured on out blog. From his description, it passed all the skilled part to the CNC shop, leaving him with a set of components which resulted in a Lego-like build.

One of our customers has just built one which is featured on out blog. From his description, it passed all the skilled part to the CNC shop, leaving him with a set of components which resulted in a Lego-like build.

Very nice job Timbre. The insides of the curved Pensil7s Chris built may have been similar, here is the skeleton for the Ellipsa which used the same curved panels, but front & back.

dave

dave

A question regarding the last two posts rather than the translam approach - sorry.

I'm contemplating a curved cabinet build and plan to have an internal structure not dissimilar to that used in the pictures on the last couple of posts - do I need to increase the internal volume to compensate for the volume of the internal structure?

Thanks

I'm contemplating a curved cabinet build and plan to have an internal structure not dissimilar to that used in the pictures on the last couple of posts - do I need to increase the internal volume to compensate for the volume of the internal structure?

Thanks

Of course. Any calculated box volume must have volume taken up by the drivers, port and bracing added on top.

do I need to increase the internal volume to compensate for the volume of the internal structure?

Yes.

dave

- Home

- Loudspeakers

- Full Range

- translam cabinets