I have almost completed Legend Stage Mk2 I just need the power supply to power it up So i need wind my transformer ............ So here r the data for the transformer winding as i am not very sure that my calculations r very correct plz help me out with this:-

CORE TYPE = EI

VA=1300

WIDTH OF CENTRAL LIMB=2 INCH

TURN PER VOLT = 1

PRIMARY CURRENT = 6.64A

PRIMARY CONDUCTOR DIAMETER =1.9mm(15 SWG)

NO OF PRIMARY WINDING = 230

SECONDARY WINDING CURRENT = 10A

SECONDARY CONDUCTOR DIAMETER = 2.488 (13 SWG)

NUMBER OF SECONDARY WINDING = 68 + 68

WINDOW AREA = 1699mm^2

PLZ HELP ME WITH THE CALCULATIONS CORRECT ME IF I AM WRONG

REGARDS

SEKHAR

CORE TYPE = EI

VA=1300

WIDTH OF CENTRAL LIMB=2 INCH

TURN PER VOLT = 1

PRIMARY CURRENT = 6.64A

PRIMARY CONDUCTOR DIAMETER =1.9mm(15 SWG)

NO OF PRIMARY WINDING = 230

SECONDARY WINDING CURRENT = 10A

SECONDARY CONDUCTOR DIAMETER = 2.488 (13 SWG)

NUMBER OF SECONDARY WINDING = 68 + 68

WINDOW AREA = 1699mm^2

PLZ HELP ME WITH THE CALCULATIONS CORRECT ME IF I AM WRONG

REGARDS

SEKHAR

IN my country the EI cores have numbers such as 6,7,8 i have no idea about EI-200 the spec of the EI core i intend to uses is

core no 43

the core no 43 as shown has a window area of 1905mm^2 but the required window area is 2043mm^2 by any means is it possible to build the transformer in the given core??????????????????????

regards

sekhar

core no 43

An externally hosted image should be here but it was not working when we last tested it.

the core no 43 as shown has a window area of 1905mm^2 but the required window area is 2043mm^2 by any means is it possible to build the transformer in the given core??????????????????????

regards

sekhar

Last edited:

errorI have almost completed Legend Stage Mk2 I just need the power supply to power it up So i need wind my transformer ............ So here r the data for the transformer winding as i am not very sure that my calculations r very correct plz help me out with this:-

CORE TYPE = EI

VA=1300

WIDTH OF CENTRAL LIMB=2 INCH

TURN PER VOLT = 1

PRIMARY CURRENT = 6.64A

PRIMARY CONDUCTOR DIAMETER =1.9mm(15 SWG)

NO OF PRIMARY WINDING = 230

SECONDARY WINDING CURRENT = 10A

SECONDARY CONDUCTOR DIAMETER = 2.488 (13 SWG)

NUMBER OF SECONDARY WINDING = 68 + 68

WINDOW AREA = 1699mm^2

PLZ HELP ME WITH THE CALCULATIONS CORRECT ME IF I AM WRONG

REGARDS

SEKHAR

window area=2043mm^2

regards

sekhar

ok, that is EI-200, i can not shake off the imperial units in my head.....i do however use both at the same time...

so you have a window of 1 inch x 3 inches, or 25mm x 75 mm.

80% of available window is for the copper wires, 50% of which is for primary coil and 50% for secondary coils.

these are your guides, the actual number of primary turns will depend on these guidelines.....

so you have a window of 1 inch x 3 inches, or 25mm x 75 mm.

80% of available window is for the copper wires, 50% of which is for primary coil and 50% for secondary coils.

these are your guides, the actual number of primary turns will depend on these guidelines.....

as u see tony the given core has a window area of 1875mm^ but the needed area is 2043mm^2 so how do i cope up with that is there any other way without using a bigger core..................??????????????????

regards

sekhar

regards

sekhar

hey cant an body help me with the design of this transformer i am newbie ,,,,,,,,,, I have done most of the calculations kindly help me in selecting the right core .................

regards

sekhar

regards

sekhar

are you using grain oriented or non-oriented steel? i ask becasue there is significant difference between two types...

ok, you need 4inch stack of 2 inch center leg core.

#15 primary will have 44turns per layer so 5 layers are needed and the copper build-up is 7.25 mm...

#13 secondary will have about 35 turns per layer, 4 layers are needed and coil build-up will be 7.6 mm..

total build-up is 14.85, so that you will still have 10mm for bobbin and insulations to play with...

i strongly reccomend you wind your secondary biffiliar so as to have exactly the same secondary voltage....

#15 primary will have 44turns per layer so 5 layers are needed and the copper build-up is 7.25 mm...

#13 secondary will have about 35 turns per layer, 4 layers are needed and coil build-up will be 7.6 mm..

total build-up is 14.85, so that you will still have 10mm for bobbin and insulations to play with...

i strongly reccomend you wind your secondary biffiliar so as to have exactly the same secondary voltage....

ok, you need 4inch stack of 2 inch center leg core.

#15 primary will have 44turns per layer so 5 layers are needed and the copper build-up is 7.25 mm...

#13 secondary will have about 35 turns per layer, 4 layers are needed and coil build-up will be 7.6 mm..

total build-up is 14.85, so that you will still have 10mm for bobbin and insulations to play with...

i strongly reccomend you wind your secondary biffiliar so as to have exactly the same secondary voltage....

I am using CRGO core or commonly refered to white core at my place .........

tony ur and my calculation does nt match

No of turns per layers in primary=3*2.54/1.9=40

no of layers required =230/40=5.75 ~ 6

Coil build up = 6 x 1.9 = 11.4mm

No of turns per layer secondary = 30

NO of layers required = 4.5 ~ 5

Coil build up = 5 x 2.488 = 12.44

total coil build up in primary & secondary = 12.44 + 11.4 = 23.8

That quite a narrow margin I think........................

And how did reach the figures that u mentioned above cause according to ur calculation

#15 primary will have 44turns per layer so 5 layers are needed and the copper build-up is 7.25 mm...(5 x 1.9 = 9.5mm)& how r u placing 44 turn in a 3inch bobin it could accomodate max 40 turn

#13 secondary will have about 35 turns per layer, 4 layers are needed and coil build-up will be 7.6 mm..(2.488 x 4= 9.952)

total build up =9.952+9.5= 19.452mm

regards

sekhar

sekhar,

i use the wire table from my ARRL 1960 handbook....they are accurate.....and magnet wires in manila conforms to dimensions from that handbook..

i used 2.75 inch winding length per layer, you should be able to fit the coils in....

i use the wire table from my ARRL 1960 handbook....they are accurate.....and magnet wires in manila conforms to dimensions from that handbook..

i used 2.75 inch winding length per layer, you should be able to fit the coils in....

could u kingly post the diameter of the 15 & 13SWG wire from the ARRL hand book 1960 so that i could cross check........................

regards

sekhar

regards

sekhar

I have not checked the arithmetic, but the consensus is that there is too much copper in your proposal to fit the window area.

You have to:

reduce the copper diameter

or

reduce the number of turns.

Where does your assumption of 1Turn/Volt on the primary come from?

Is this in any way related to ampere turns for that size of core?

BTW,

65Vac on maximum load and 68Vac on zero load indicates a regulation of 4.5%.

This seems unusually low for an EI, even a big one.

You have to:

reduce the copper diameter

or

reduce the number of turns.

Where does your assumption of 1Turn/Volt on the primary come from?

Is this in any way related to ampere turns for that size of core?

BTW,

65Vac on maximum load and 68Vac on zero load indicates a regulation of 4.5%.

This seems unusually low for an EI, even a big one.

As this is a 1300VA transformer turn per volt as indicated by tony is near to 1.083 so i assumed turn per volt to be 1 .......

And 68+68 turns on the secondary side is a bit more than needed as i have kept 5 % extra to compensate for copper loss heating lose etc......

any idea how to decrease copper diameter or reduce number of turn......by any means is it possible to make this 1300VA transformer............

regards

sekhar

And 68+68 turns on the secondary side is a bit more than needed as i have kept 5 % extra to compensate for copper loss heating lose etc......

any idea how to decrease copper diameter or reduce number of turn......by any means is it possible to make this 1300VA transformer............

regards

sekhar

do you know the ampere turns required for this core?

Or, is Tony's information all you have for your proposal?

Or, is Tony's information all you have for your proposal?

sekhar,

this table is very simmilar to mine : Copper Wire Table

for #15 wire, diameter is 1.45, then for #13, diameter is 1.824, so that if you go back to my post # 9, the numbers should add up...

besides a i have done a 2 inch center leg transformer a few months back, i used #15 primary....

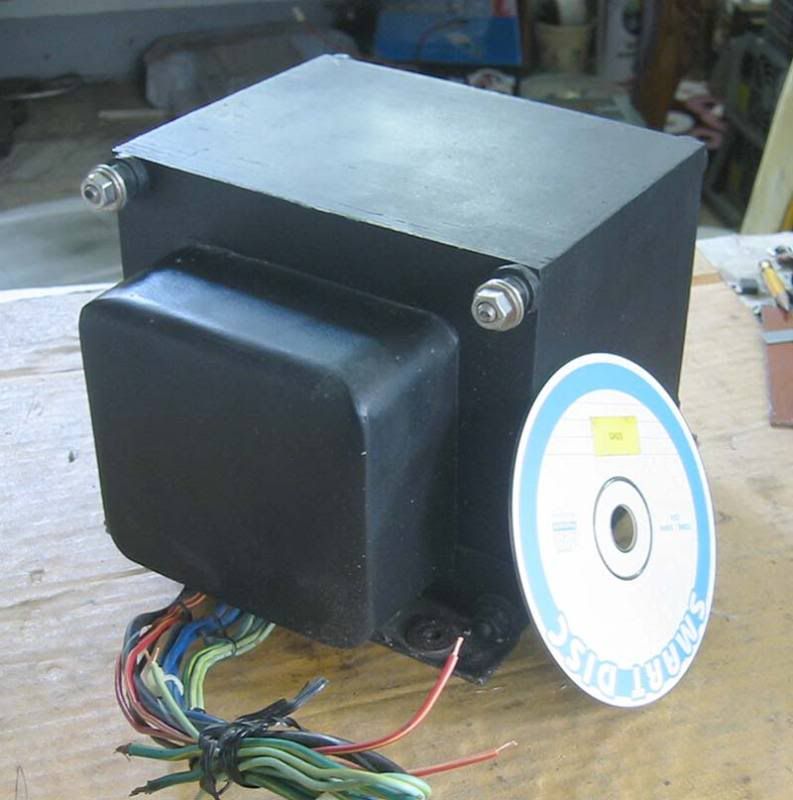

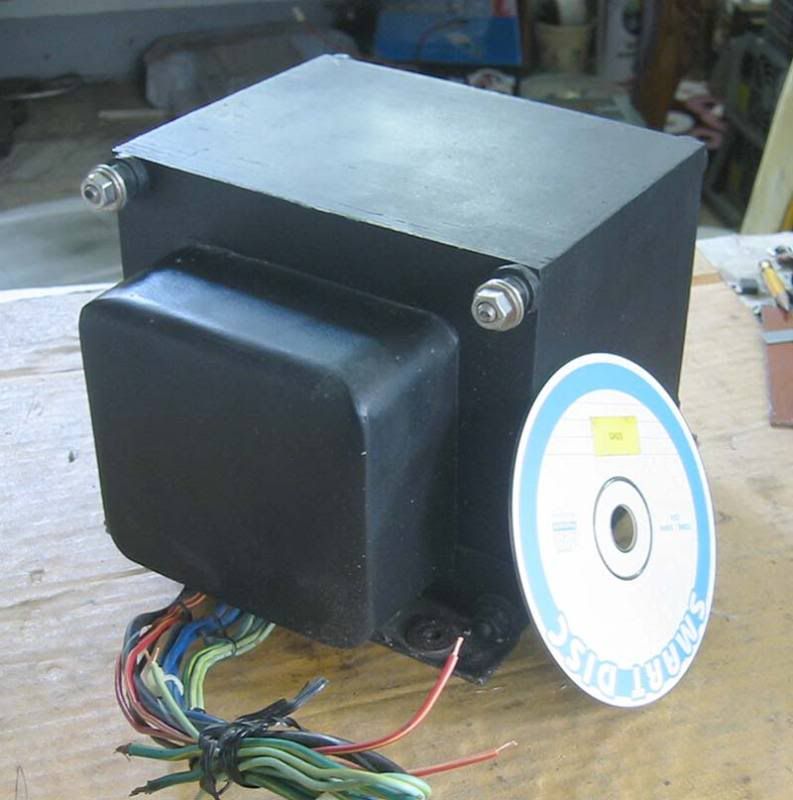

this traffo uses a 2 1/4 inch x 5 1/2 inch stack...

this table is very simmilar to mine : Copper Wire Table

for #15 wire, diameter is 1.45, then for #13, diameter is 1.824, so that if you go back to my post # 9, the numbers should add up...

besides a i have done a 2 inch center leg transformer a few months back, i used #15 primary....

An externally hosted image should be here but it was not working when we last tested it.

this traffo uses a 2 1/4 inch x 5 1/2 inch stack...

in case you wires are different, you can check it out here: http://upload.wikimedia.org/wikipedia/en/2/28/Gauge_Chart.pdf

ok, i get it now, you are using the British standard, i am using American standard, therefore your wire sizes are bigger than mine....

so what you need actually is #17 instead of #15, then #17 instead of #15...in terms of British standard sizes.....

so what you need actually is #17 instead of #15, then #17 instead of #15...in terms of British standard sizes.....

design sheet for a 220volt primary, 65-0-65 volt @10 amp secondary power transformer:

1. Choose core size equals 2 inch center leg stacked 4 inches in height.

2. Core area equals 2 x 4 inches = 8 inches squared.

3. Core VA rating per RDH4, chapter5 = VA= (Ax5.58)^2 = (8*5.58)^2 = 1992,

4. Secondary VA = 130 x 10 = 1300,

5. Primary VA = 1300/0.8 = 1625, choice of core dimensions are validated.

6 Primary turns Np = 1700/= 212.5 turns, reffer to RDH4 chapter5

7. Primary coil:

7.1 Choose AWG # 15, (american wire gauge), diam. = 1.45mm.;

16.5 turns per inch; 104 ft/lb.; 3.247ohms/kFeet

7.2 Use coil width of 2.75 inches, turns per layer = 2.75 x 16.5 = 45.375, use 44 tpl.

7.3 number of layers = 44 x 5 = 220 turns. (we use this number instead of in #6)

7.4 Lenght of primary winding = (220 x 13)/12 = 238ft.

7.5 Weight of primary coil = 238 / 104 = 2.28lb. ~ 1kg.

7.6 Resistance of primary coil = (3.247 x 238)/1000 = 0.77 ohms

8. Secondary coil:

8.1 Secondary windings use 2 coils wound biffiliar with 65 turns of AWG #13,;

diam. = 1.9mm.; 13.5 turns per inch; 63.5 ft./lb.; 2.012 ohms/kFeet

8.2 Use coil width of 2.75 inches, turns per layer = 2.75 x 13.5 = 37, use 35 tpl.

8.3 Number of layers = 130/35 = 3.57 ~ 4 layers,

8.4 You have space to use 2 x 66 turn coils.

8.5 Lenght of secondary winding = (130 x 14)/12 = 151ft.

8.6 Weight of secondary coil = 151 / 63.5 = 2.38lb. ~ 1.+kg.

8.7 Resistance of secondary coil = (151 x 2.012)/1000 = 0.304 ohms

9. Weight of built-up transformer:

9.1 Weight of copper : 5.66lbs or 2.57kgs.

9.2 Weight of iron core : 25.92lbs or 11.78kgs, ~12kgs(you can not buy a fraction of a kg.)

9.3 Total wieght of transformer = 5.66 + 25.92 = 31.58lbs. or 14.35kgs.

10. Efficiency:

10.1 Copper losses: @ 1300watts ouput = (5.9^2 x 0.77) = 24.7 watts;

10.2 Iron core loss ; @1.5watts per kg = 21.05watts

10.3 total losses = 45.75 watts

10.4 Full load efficiency = [(1300-45.75)/1300] x 100% = 96.4%

1. Choose core size equals 2 inch center leg stacked 4 inches in height.

2. Core area equals 2 x 4 inches = 8 inches squared.

3. Core VA rating per RDH4, chapter5 = VA= (Ax5.58)^2 = (8*5.58)^2 = 1992,

4. Secondary VA = 130 x 10 = 1300,

5. Primary VA = 1300/0.8 = 1625, choice of core dimensions are validated.

6 Primary turns Np = 1700/= 212.5 turns, reffer to RDH4 chapter5

7. Primary coil:

7.1 Choose AWG # 15, (american wire gauge), diam. = 1.45mm.;

16.5 turns per inch; 104 ft/lb.; 3.247ohms/kFeet

7.2 Use coil width of 2.75 inches, turns per layer = 2.75 x 16.5 = 45.375, use 44 tpl.

7.3 number of layers = 44 x 5 = 220 turns. (we use this number instead of in #6)

7.4 Lenght of primary winding = (220 x 13)/12 = 238ft.

7.5 Weight of primary coil = 238 / 104 = 2.28lb. ~ 1kg.

7.6 Resistance of primary coil = (3.247 x 238)/1000 = 0.77 ohms

8. Secondary coil:

8.1 Secondary windings use 2 coils wound biffiliar with 65 turns of AWG #13,;

diam. = 1.9mm.; 13.5 turns per inch; 63.5 ft./lb.; 2.012 ohms/kFeet

8.2 Use coil width of 2.75 inches, turns per layer = 2.75 x 13.5 = 37, use 35 tpl.

8.3 Number of layers = 130/35 = 3.57 ~ 4 layers,

8.4 You have space to use 2 x 66 turn coils.

8.5 Lenght of secondary winding = (130 x 14)/12 = 151ft.

8.6 Weight of secondary coil = 151 / 63.5 = 2.38lb. ~ 1.+kg.

8.7 Resistance of secondary coil = (151 x 2.012)/1000 = 0.304 ohms

9. Weight of built-up transformer:

9.1 Weight of copper : 5.66lbs or 2.57kgs.

9.2 Weight of iron core : 25.92lbs or 11.78kgs, ~12kgs(you can not buy a fraction of a kg.)

9.3 Total wieght of transformer = 5.66 + 25.92 = 31.58lbs. or 14.35kgs.

10. Efficiency:

10.1 Copper losses: @ 1300watts ouput = (5.9^2 x 0.77) = 24.7 watts;

10.2 Iron core loss ; @1.5watts per kg = 21.05watts

10.3 total losses = 45.75 watts

10.4 Full load efficiency = [(1300-45.75)/1300] x 100% = 96.4%

ok, i get it now, you are using the British standard, i am using American standard, therefore your wire sizes are bigger than mine....

so what you need is actually #17 instead of #15, then #15 instead of #13...in terms of British standard sizes.....

corrected to read right...😀

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- transformer for Legend Stage MK2 (65-0-65V)@10A