as above.

I was browsing audiophonics.fr and came across these: https://www.audiophonics.fr/en/tran...for-toroidal-transformer-120x65mm-p-8969.html

unsure if it's for aesthetics only or it actually works to shield the transformer from the rest of the device.

Thanks

I was browsing audiophonics.fr and came across these: https://www.audiophonics.fr/en/tran...for-toroidal-transformer-120x65mm-p-8969.html

unsure if it's for aesthetics only or it actually works to shield the transformer from the rest of the device.

Thanks

The first thing that came to my mind seeing this transformer cover is the fact a transformer needs to be kept cool. This cover prevents the air from circulating around the transformer making cooling more difficult to achieve. Old transformers had metal covers for the coils but the core was left uncovered.

I experienced serious issues with transformers inducing mains related garbage into my amplification circuitry inside my tightly packed amplifier chassis.

I put such covers over the toroid transformers hoping to reduce mains induction into the audio circuitry.

Note that there are also matching base plates available, yielding somewhat better shielding.

The measured effect from shielding the toroid transformers (cheap industry standard ones) was rather low (~3dB).

It turned out that the main offenders were some small E-I core transformers (5VA to 10VA) used for auxiliary power supplies.

Shielding the E-I core transformers had far more dramatic impact and removing some of them improved the situation even more.

However, those covers look very nice.

As pointed out by edbarx, such covers likely hinder cooling of the transformers.

However, amplifier transformers used in domestic environments are rather unlikely to run into thermal issues unless you party hard.

I put such covers over the toroid transformers hoping to reduce mains induction into the audio circuitry.

Note that there are also matching base plates available, yielding somewhat better shielding.

The measured effect from shielding the toroid transformers (cheap industry standard ones) was rather low (~3dB).

It turned out that the main offenders were some small E-I core transformers (5VA to 10VA) used for auxiliary power supplies.

Shielding the E-I core transformers had far more dramatic impact and removing some of them improved the situation even more.

However, those covers look very nice.

As pointed out by edbarx, such covers likely hinder cooling of the transformers.

However, amplifier transformers used in domestic environments are rather unlikely to run into thermal issues unless you party hard.

If your transformer is getting that hot for any home related application, I would first seriously reconsider some other things.The first thing that came to my mind seeing this transformer cover is the fact a transformer needs to be kept cool. This cover prevents the air from circulating around the transformer making cooling more difficult to achieve. Old transformers had metal covers for the coils but the core was left uncovered.

Because that is not normal behavior. At home levels, a transformer should be getting just about a bit warm at worst.

Most toroidal transformers have an efficiency of about 90-95%, some even higher.

All that being said, if you're still worried about heat, just drilling a few small holes will be good enough to get rid of most of the "heat" while still working fine as a shield.

Last edited:

If they work and how well they work, depends quite a bit on the transformer that is been in use.as above.

I was browsing audiophonics.fr and came across these: https://www.audiophonics.fr/en/tran...for-toroidal-transformer-120x65mm-p-8969.html

unsure if it's for aesthetics only or it actually works to shield the transformer from the rest of the device.

Thanks

If the transformer itself already has a electrostatic screen as well as a magnetic screen, there isn't much to gain anymore.

From a personal experience, based on quite some years of experience in production, I would say it's mostly aesthetics.

Mostly also, because an open hex mesh structure would be fine for most high frequency interference.

Toiroidal transformers need to be shielded even better than the EI transformers, since they nearly radiate at 360° for electric field disturbance, not to say magnetic too... They are very far from their urban legend of quietness and low radiation attributed to them ! I discovered this the hard way on previous projects...

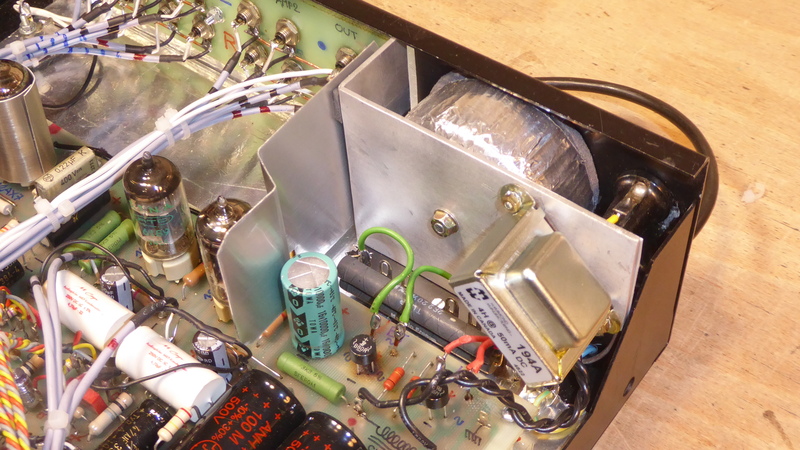

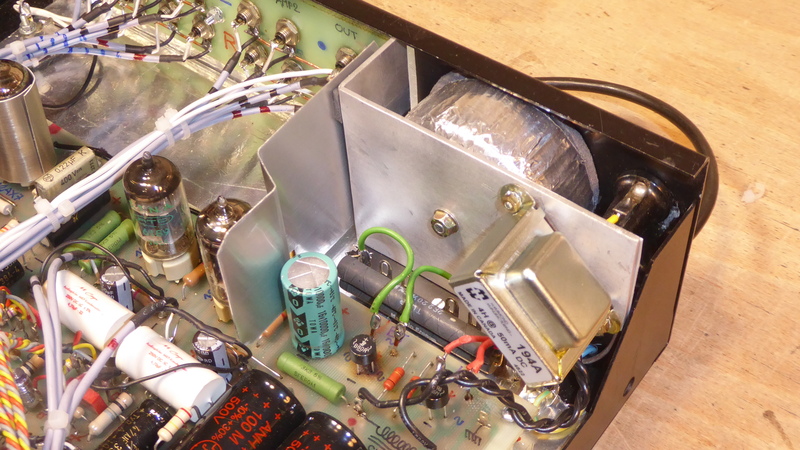

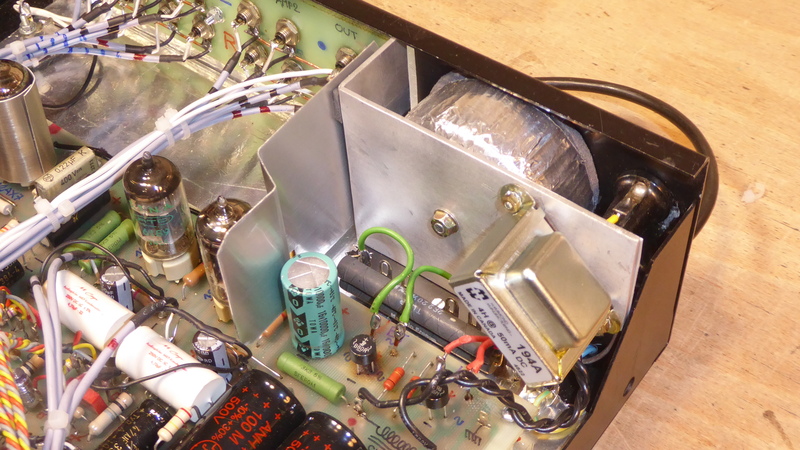

Here's what I did on the small toroidal transformer of my tube preamplifier :

I wrapped he transformer itself in a 3-layers aluminium adhesive foil all around - EXCEPT THE CENTRE of the toiroid, in order to avoid the fatal short loop - to kill electric/electrostatic radiation.

The center screw is brass - non magnetic.

I also put 2mm alumium screen to cut any remaining magnetic radiation, plus a second screen (0.5mm) around the tubes and circuits that are close.

Aluminium is much more efficient than steel for shielding a transformer because it is a paramagnetic metal. I also discovered this the hard way on previous projects...

If the cover you presented us was made from aluminium, I would have said go without any hesitation (please add a bottom to close it !), but since it is steel, I'm not sure that it will be very efficient - as pointed by @Lee Knatta in his post - so you must test to know if it is enough !

Nonetheless, you can try to cover the exterior and interior of that steel cap with adhesive aluminium foil : it could certainly improve the shielding effect...

T

Here's what I did on the small toroidal transformer of my tube preamplifier :

I wrapped he transformer itself in a 3-layers aluminium adhesive foil all around - EXCEPT THE CENTRE of the toiroid, in order to avoid the fatal short loop - to kill electric/electrostatic radiation.

The center screw is brass - non magnetic.

I also put 2mm alumium screen to cut any remaining magnetic radiation, plus a second screen (0.5mm) around the tubes and circuits that are close.

Aluminium is much more efficient than steel for shielding a transformer because it is a paramagnetic metal. I also discovered this the hard way on previous projects...

If the cover you presented us was made from aluminium, I would have said go without any hesitation (please add a bottom to close it !), but since it is steel, I'm not sure that it will be very efficient - as pointed by @Lee Knatta in his post - so you must test to know if it is enough !

Nonetheless, you can try to cover the exterior and interior of that steel cap with adhesive aluminium foil : it could certainly improve the shielding effect...

T

Last edited:

Actually, the whole point of the toroidal wounding shape, is that they are self shielding.Toiroidal transformers need to be shielded even better than the EI transformers, since they nearly radiate at 360° for electric field disturbance, not to say magnetic too...

https://en.wikipedia.org/wiki/Toroidal_inductors_and_transformers

The advantage of the toroidal shape is that, due to its symmetry, the amount of magnetic flux that escapes outside the core (leakage flux) can be made low, potentially making it more efficient and making it emit less electromagnetic interference (EMI).

sample pic? Thanks a lot.Mostly also, because an open hex mesh structure would be fine for most high frequency interference.

Actually, the whole point of the toroidal wounding shape, is that they are self shielding.

https://en.wikipedia.org/wiki/Toroidal_inductors_and_transformers

Very far from that, for sure : they are simply hum, dzzz and parasitic spreaders, sensitive to all sort of disturbances coming on the mains network (RF, spikes, DC offset). They are ideal transformer wannabees, that just work perfectly on a perfect situation at the secondary and primary, and this never arises. They need indeed to be shielded ! And if yes, then they can be used in sensitive circuits...

In comparison, an EI transformer is much less prone to mains network disturbances, radiates much less magnetic and electric induction if it is fitted with a flux band, correctly impregnated, and moreover, the magnetic induction is identified in direction, following the center core of the laminations.

This induction flux is easy to counteract, simply with a 2 to 4mm aluminium screen placed in the right direction. It's not even necessary to encase the whole transformer to be efficient. Here's what I did on a High-Gain 100WRMS guitar amplifier, by the two "wings" around the power transformer :

Before that, I used a first toroidal transformer : a total hum and buzzz nightmare...

To the extent that I suspected it to be defective, and replaced it by another one installed under a cover (made of steel, similar to the one the OP speaks about) :

Some little improvement was noted with the new transformer under its shield, but the amp was still not S/N ratio acceptable for me as is, even the guitar pickups (humbuckers) picked the induction at a 2m distance, at home volume. The induction could be also heard in the EVM12L speaker...

All these disturbances completely disappeared when I shifted to the EI transformer, with added copper flux band and aluminium shielding wings. The amp is now definetly hum and buzzz dead-silent, no hum picked by guitars anymore...

Now you understand why I am suspicious about toroidal and R-core transformers quietness, absence of radiation and self-shielding properties, despite what can be written about them on the subject !

T

Last edited:

Guess all electronics books an wikipedia are wrong than?Very far from that, for sure : they are simply hum, dzzz and parasitic spreaders,

Time to write some people ta ask if they can change these things in the literature.

Any electrically conductive metal looping through the toroid will conduct current giving you a shorted turn. Brass is conductive.I wrapped he transformer itself in a 3-layers aluminium adhesive foil all around - EXCEPT THE CENTRE of the toiroid, in order to avoid the fatal short loop - to kill electric/electrostatic radiation.

The center screw is brass - non magnetic.

Any bolt through the center must be elecrtrically isolated on one side.

Duke

Be careful that the bolt, aluminum mounting panel and rear panel don't form the equivalent of a shorted turn around the toroid.Toiroidal transformers need to be shielded even better than the EI transformers, since they nearly radiate at 360° for electric field disturbance, not to say magnetic too... They are very far from their urban legend of quietness and low radiation attributed to them ! I discovered this the hard way on previous projects...

Here's what I did on the small toroidal transformer of my tube preamplifier :

I wrapped he transformer itself in a 3-layers aluminium adhesive foil all around - EXCEPT THE CENTRE of the toiroid, in order to avoid the fatal short loop - to kill electric/electrostatic radiation.

The center screw is brass - non magnetic.

I also put 2mm alumium screen to cut any remaining magnetic radiation, plus a second screen (0.5mm) around the tubes and circuits that are close.

Aluminium is much more efficient than steel for shielding a transformer because it is a paramagnetic metal. I also discovered this the hard way on previous projects...

If the cover you presented us was made from aluminium, I would have said go without any hesitation (please add a bottom to close it !), but since it is steel, I'm not sure that it will be very efficient - as pointed by @Lee Knatta in his post - so you must test to know if it is enough !

Nonetheless, you can try to cover the exterior and interior of that steel cap with adhesive aluminium foil : it could certainly improve the shielding effect...

T

I never had problems with toroid transformers giving hum or buzz from inductive coupling - but don't use them in guitar amps.

The main reason for useing this form is a tight coupling of primary to secondary side. And in addition you get huge capacitive coupling between them. That's exactly what you DON'T want from a mains transformer - you want it to block every high frequency as good as possible, esp nowadays.

Use toroid for signal transformers, but not in sensitive audio circuits as mains transformers.

The main reason for useing this form is a tight coupling of primary to secondary side. And in addition you get huge capacitive coupling between them. That's exactly what you DON'T want from a mains transformer - you want it to block every high frequency as good as possible, esp nowadays.

Use toroid for signal transformers, but not in sensitive audio circuits as mains transformers.

Member

Joined 2009

Paid Member

As far as I know, there’s a few options (assuming you can’t move the transformers further away)

a) minimize radiating loops, look at the wires coming off the transformer, especially anything carrying high current spikes, and make sure they are short and twisted together; put rectifiers and first caps close to the transformer.

b) minimize receiving loops in nearby circuits

c) add a ‘belly strap’ to the transformer with copper sheet (google it for details) to reduce leaking flux

d) use steel (not stainless) or iron shields for magnetic containment

d) if you can, rotate the transformer (maybe a new mounting plate on top of the original mounting holes)

e) if desperate try injecting an adjustable cancelling hum into the circuit (tube guys)

I suspect lightweight Al covers are mostly going to be useful for cosmetic reasons only?

a) minimize radiating loops, look at the wires coming off the transformer, especially anything carrying high current spikes, and make sure they are short and twisted together; put rectifiers and first caps close to the transformer.

b) minimize receiving loops in nearby circuits

c) add a ‘belly strap’ to the transformer with copper sheet (google it for details) to reduce leaking flux

d) use steel (not stainless) or iron shields for magnetic containment

d) if you can, rotate the transformer (maybe a new mounting plate on top of the original mounting holes)

e) if desperate try injecting an adjustable cancelling hum into the circuit (tube guys)

I suspect lightweight Al covers are mostly going to be useful for cosmetic reasons only?

and i thought that toroids ought to have lower radiated fields due the the fact the it has no air gaps to speak of compared to EI's that have three....

oh well, things are not so dandy with toroids after all...people still find things to complain about them...

oh well, things are not so dandy with toroids after all...people still find things to complain about them...

Last edited:

Hello, did you have to connect the cover to earth ground? (I'm guessing yes only because it's outside the chassis? what if it's inside the chassis?)To the extent that I suspected it to be defective, and replaced it by another one installed under a cover (made of steel, similar to the one the OP speaks about) :

Thanks again

Last edited:

Be careful that the bolt, aluminum mounting panel and rear panel don't form the equivalent of a shorted turn around the toroid.

Indeed : there's a rubber insulation between the two faces, avoiding the short turn. I used a shielded toroid here because I did not have enough room to install suitably a good quality EI transformer...

Hello, did you have to connect the cover to earth ground? (I'm guessing yes only because it's outside the chassis? what if it's inside the chassis?)

Thanks again

On my Serial Tone Killer guitar amp, the cover of that second todoid test was grounded de facto. But it had no significant influence on the radiations, unfortunately... The problem was eradicated by shifting to the EI high-grade lamination transformer, plus its added two aluminium wings :

T

- Home

- Amplifiers

- Power Supplies

- transformer covers - do these work?