while I was doing research, I met this website with the toroidal question asked on the forum. I realized later that there was a site related to sound systems. I would like to ask a question about toroidal transformers. i want to use the toroidal transformer with a dc motor. but I don't know how many amps this transformer has. there are only volt values on the label on the transformer. how can I find the ampere value of the toroidal transformer? i want to connect a 24v 5a dc motor to a transformer, does this cause problems?

To much guessing what there is written on that toroid, cannot see it clearly. But from the picture, this transformer looks quite small, nothing close to what you need for a 24V/5A dc powersupply. With cap input, you will need a 200VA transformer at least.

Last edited:

Dunker motors are good quality and id there is no restriction (at least there is nothing i can see on the picture)on the duty cycle they are usually usable with 100% duty cycle.

For low duty cycle, like adjusting a bed, this 0.95kg transformer could be enough, it will not burn up.

The continous load rating of your transformer is ca 80VA.

For low duty cycle, like adjusting a bed, this 0.95kg transformer could be enough, it will not burn up.

The continous load rating of your transformer is ca 80VA.

Last edited:

The toroid looks a little small. No more than 50 VA, judging by size. What’s needed is 24V/5A, or 120 VA for continuous duty. At intermittent duty a smaller one can be used.To much guessing what there is written on that toroid, cannot see it clearly. But from the picture, this transformer looks quite small, nothing close to what you need for a 24V/5A dc powersupply. With cap input, you will need a 200VA transformer at least.

No need for a cap input supply. Just stick a rectifier between the trafo and the motor and as long as voltage is compatible you’re good to go. The motor’s inductance is all the filtering needed. I run winch motors (ones found on Jeeps) with a 15 V/600 VA toroid and rectifier. Works perfectly. Even if it draws more than 40A under heavy load for a few seconds raising a 240 pound speaker cab up to the 2nd level in the shop.

Wg_ski, 0.95kg toroids are normally rated 80VA. Also, raw dc works but is tuffer on collector and brushes

Okutkan, the 40V motor is the same power but seems to have a 10:1 reduction gearbox so more suitable i thinck.

I have a small russian lathe, 80mm chuck, has a 0.55kW motor, 100-2500rpm, but i got tired of changing belts and pulleys.

I mostly run it now without pulleys and directdrive the mainshaft with a powerfull cordless drill. Works okay turning smallish diam. parts and threading brassrods up to M10.

Okutkan, the 40V motor is the same power but seems to have a 10:1 reduction gearbox so more suitable i thinck.

I have a small russian lathe, 80mm chuck, has a 0.55kW motor, 100-2500rpm, but i got tired of changing belts and pulleys.

I mostly run it now without pulleys and directdrive the mainshaft with a powerfull cordless drill. Works okay turning smallish diam. parts and threading brassrods up to M10.

Last edited:

Less current load YES, less power load NOI will use a drill cap as a header. there are only those who write in the photo on the engine. the second engine is rated at 40v and 3amper. if I use this motor, will there be less load on the transformer?

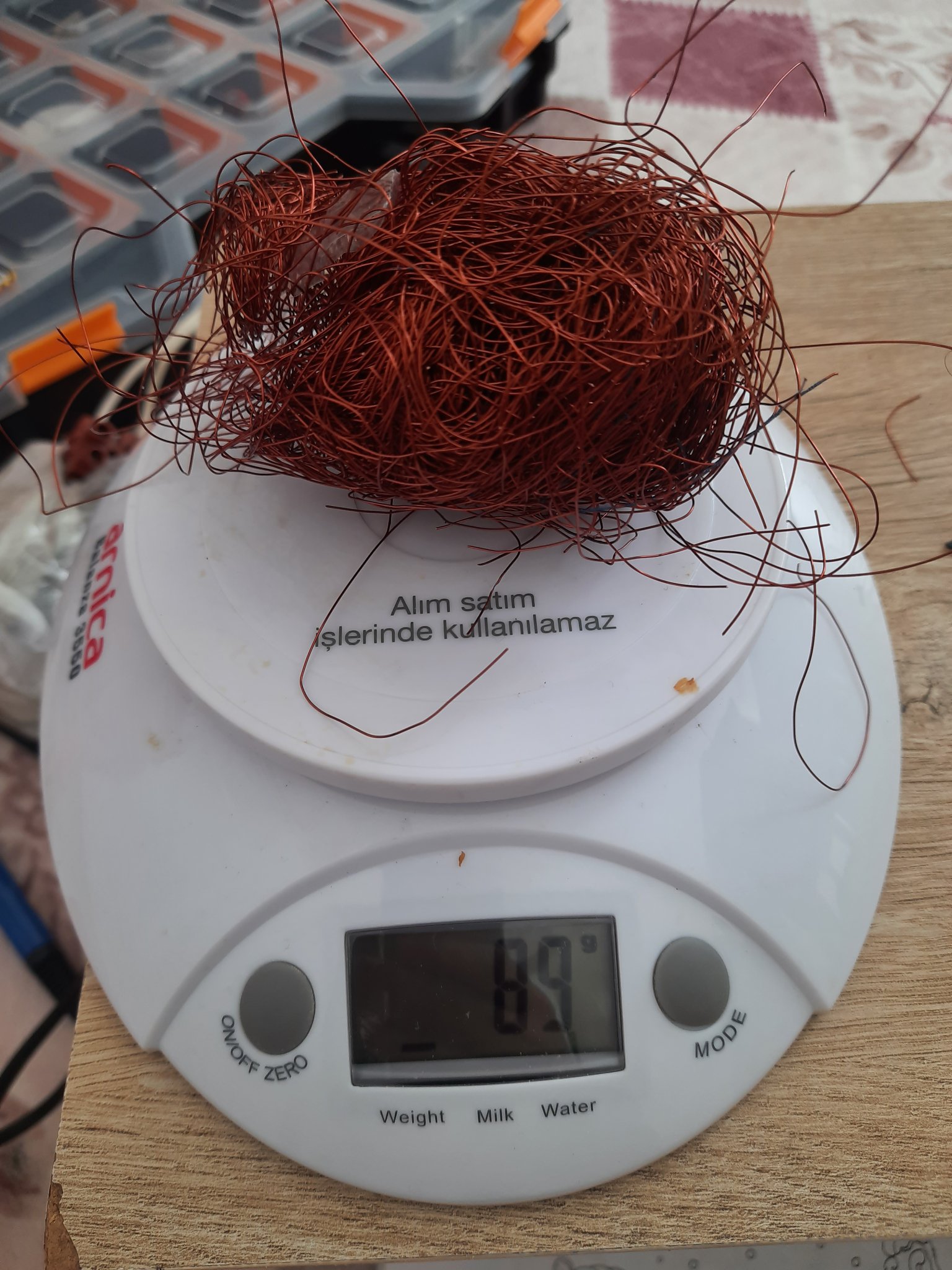

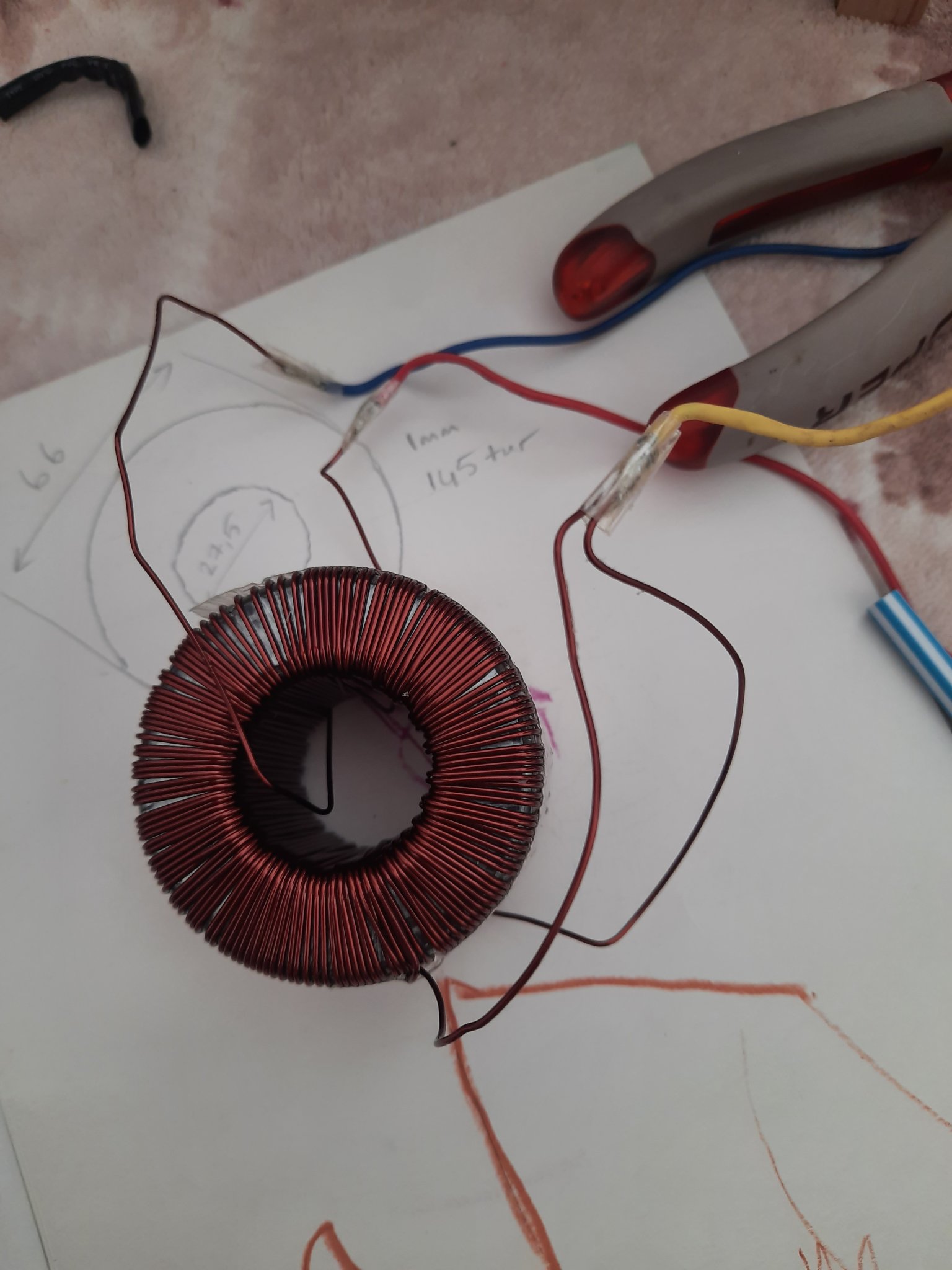

I took apart a transformer whose wires were damaged. the measurements are as they appear in the photo.

(thick cable with inner winding 1mm, yellow-red: 12meter, yellow-blue:4.2mt, total:16.2meters, weight:100gram, number of winding turns:145)

(thin cable with outer winding thickness 0.3mm, weight: 90gram)

(core inner diameter 31mm, outer diameter 63, weight: 680gram)

(inner diameter 17, thickness 30mm, height when the winding is not disassembled)

(inner diameter 17, thickness 30mm, height 49.5mm)

(output voltage values: yellow-red 23v, yellow-blue 7.7v, red-blue 31v)

sorry for the mispronunciations because I use yandex translate.

(thick cable with inner winding 1mm, yellow-red: 12meter, yellow-blue:4.2mt, total:16.2meters, weight:100gram, number of winding turns:145)

(thin cable with outer winding thickness 0.3mm, weight: 90gram)

(core inner diameter 31mm, outer diameter 63, weight: 680gram)

(inner diameter 17, thickness 30mm, height when the winding is not disassembled)

(inner diameter 17, thickness 30mm, height 49.5mm)

(output voltage values: yellow-red 23v, yellow-blue 7.7v, red-blue 31v)

sorry for the mispronunciations because I use yandex translate.

Attachments

16.2m of 1mm Cull should weigth 115g, so something does not add up. If secondary weigth and lenngth are correct your wire could be single isolated 0.95mm.

If so, that would give a nominal area of 0.70882 squ mm, and at current density of 4A/squ mm, max secondary current is 2.83A.

Secondary seems to be a nominal rated 28V 80VA.

With output taken at the unloaded 23V tap current density would be 5.6A/squ mm with 4A=80VA load.

Primary seems to be 157-162m of 0.28mm so current density at the outside primary winding is also a bit high, but should be ok because cooling is better.

Regulation is about 10%.

Alltough, the secondary has at 25°C only a resistance of 0.39ohm, at full load the voltage will drop around 10% because the primary loss is comparable higher..

So, all secondary windings serial connected, 28V, 2.8A, not enough for continous operation of your motor, but maybe ok for intermittend use if you watch the temperature.

If so, that would give a nominal area of 0.70882 squ mm, and at current density of 4A/squ mm, max secondary current is 2.83A.

Secondary seems to be a nominal rated 28V 80VA.

With output taken at the unloaded 23V tap current density would be 5.6A/squ mm with 4A=80VA load.

Primary seems to be 157-162m of 0.28mm so current density at the outside primary winding is also a bit high, but should be ok because cooling is better.

Regulation is about 10%.

Alltough, the secondary has at 25°C only a resistance of 0.39ohm, at full load the voltage will drop around 10% because the primary loss is comparable higher..

So, all secondary windings serial connected, 28V, 2.8A, not enough for continous operation of your motor, but maybe ok for intermittend use if you watch the temperature.

Last edited:

I correct, primary of over 150m length seems a bit to long even it is wound on top.

If the wire is actually 0.3mm without isolation (actual diam can vary from 0.319-0.334mm for single isolated, to 0.335-0.352mm for double) only 135-140m would be needed to giv a weigth a 90g. 25°C primary resistance would drop from the 0.28mm 42-43ohm to much more reasonable 33-34 ohm

This would also bring the primary current density to the same level as the tapped secondary.

If the wire is actually 0.3mm without isolation (actual diam can vary from 0.319-0.334mm for single isolated, to 0.335-0.352mm for double) only 135-140m would be needed to giv a weigth a 90g. 25°C primary resistance would drop from the 0.28mm 42-43ohm to much more reasonable 33-34 ohm

This would also bring the primary current density to the same level as the tapped secondary.

For continous full load operation everything in that PS is undersized but its ok for a test drive i guess.

With 2A heat losses will be 16 times, and with full load 2.95A ca. 35 times higher than with the no load current of 0.5A.

Add to this 1% additional loss for every 2.5°C temperature increase of the windings and 35 becomes easely 50 or more,

With 2A heat losses will be 16 times, and with full load 2.95A ca. 35 times higher than with the no load current of 0.5A.

Add to this 1% additional loss for every 2.5°C temperature increase of the windings and 35 becomes easely 50 or more,

Last edited:

- Home

- Amplifiers

- Power Supplies

- Toroidal & DC motor